Preparation method of solvent-resistant high-dielectric-constant insulating layer capable of being simply and conveniently patterned

A high dielectric constant, patterned technology, applied in circuits, electrical components, transistors, etc., can solve problems such as less mention, and achieve the effect of reducing operating voltage, reducing solvent entry, and increasing dielectric constant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] An embodiment of the present invention provides a method for preparing a solvent-resistant high dielectric constant insulating layer material that can be easily patterned, including the following steps:

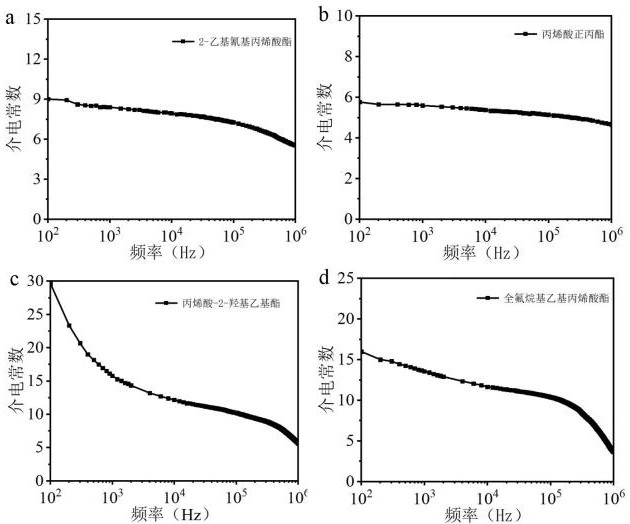

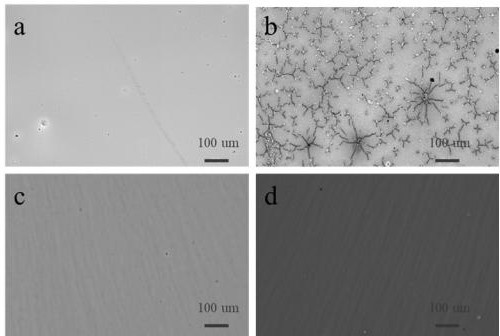

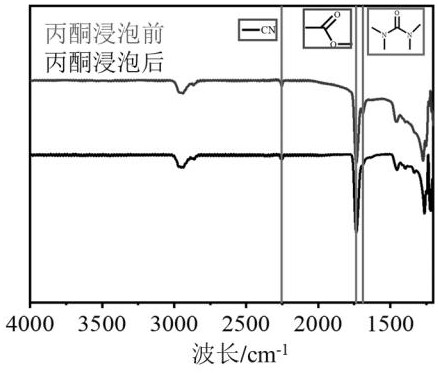

[0053] (1) Dissolve 2-ethylcyanoacrylate (CEA) (0.07 g) and 1,6-hexanediol diacrylate (HDDA) (0.03 g) at a mass ratio of 7:3 into 1 mL THF solvent In , a solution with a mass fraction of CEA and HDDA of 10 wt% was prepared, and then azobisisobutyronitrile (0.003 g) with a mass sum of CEA and HDDA of 3 wt% (0.003 g) was added to obtain a mixed solution. The mixed solution was degassed by ultrasonic oscillation for 2 min, and then placed in a 40 mw / cm 2 Under 365 nm ultraviolet light for 60 min, the premix was obtained.

[0054] (2) Heat the premix in a water bath at 60 °C for 2 h, then add triallyl isocyanurate, benzoin dimethyl ether, benzophenone, and triethylamine, then dilute with a solvent, and ultrasonically oscillate to obtain a clear solution , the mass fracti...

Embodiment 2

[0057] A method for preparing a solvent-resistant high dielectric constant insulating layer material that can be easily patterned. The difference from Example 1 is that CEA is not added in step (1), and 2-hydroxyethyl acrylate is used instead of CEA Dissolve in tetrahydrofuran solvent.

Embodiment 3

[0059] A method for preparing a solvent-resistant high dielectric constant insulating layer material that can be easily patterned, the difference from Example 1 is that CEA is not added in step (1), and CEA is replaced by perfluoroalkyl ethyl acrylate Dissolve in tetrahydrofuran solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com