Preparation method of disperse scarlet

A scarlet and dispersing technology, applied in the field of preparation of disperse scarlet, can solve the problems of increasing production cost, generation of three wastes, dust generation, etc., and achieve the effect of reducing waste water discharge, reducing side reactions, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

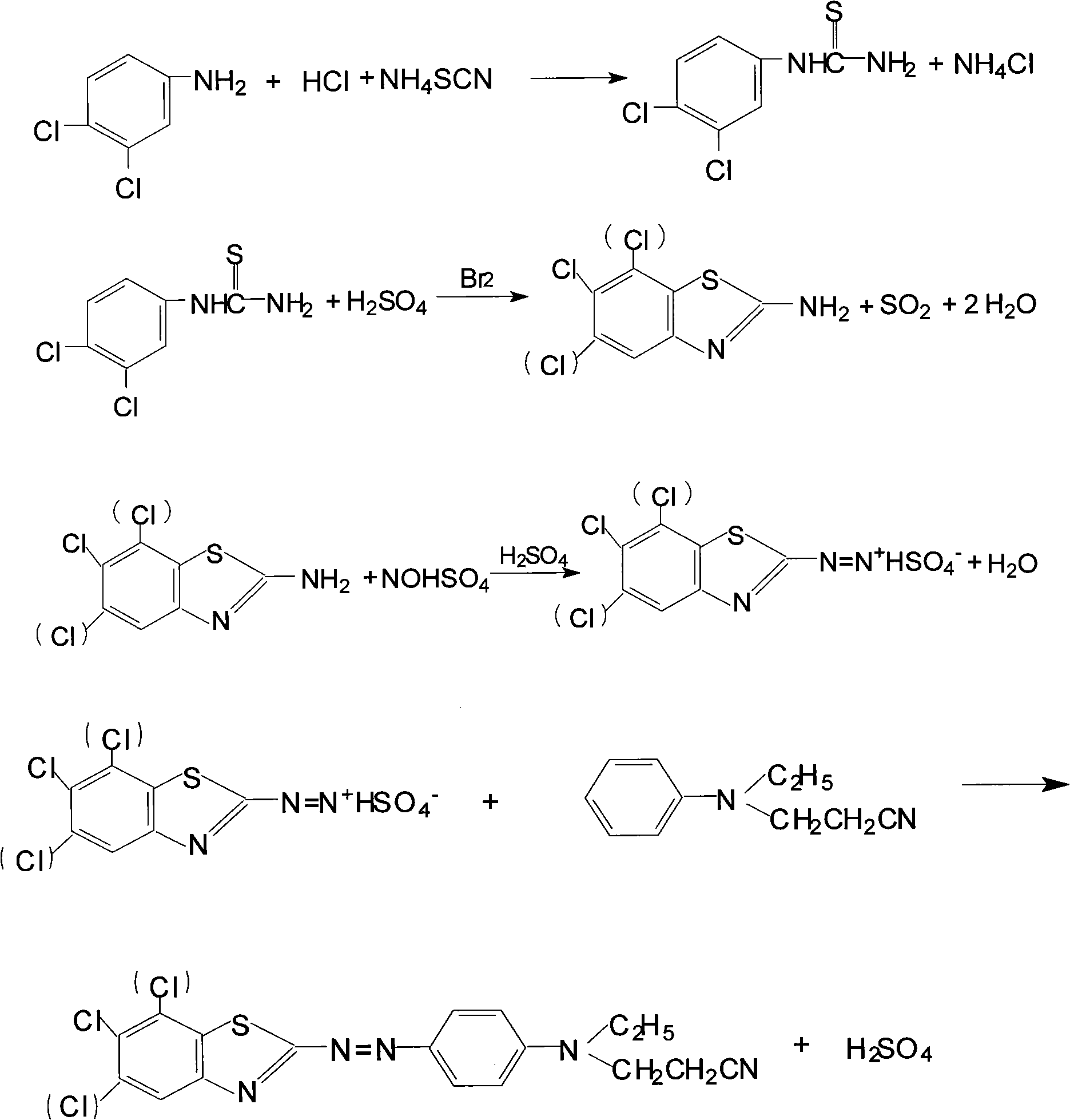

Image

Examples

Embodiment 1

[0030] Example 1. A preparation method for dispersing scarlet, the steps are as follows:

[0031] (1) Preparation of thiourea: Pour appropriate amount of tap water into the reaction kettle, put in 3,4-dichloroaniline after heating up to 60°C, and stir to fully dissolve the material after throwing in, and the dissolution temperature is 60°C; Add hydrochloric acid to the kettle dropwise, immediately after dropping, add ammonium thiocyanate aqueous solution, and immediately add the remaining hydrochloric acid; then raise the temperature to 80°C and keep warm for reaction, and cool and crystallize after the reaction; discharge and filter to obtain thiourea and mother liquor water 1, thiourea is washed with water to neutrality, and dried to obtain thiourea; the weight ratio of the 3,4-dichloroaniline, hydrochloric acid, and ammonium thiocyanate is 1: 0.5: 0.4; the hydrochloric acid added dropwise for the first time is hydrochloric acid 3 / 4 of the total weight;

[0032] (2) Closed...

Embodiment 2

[0035] Example 2. A preparation method for dispersing scarlet, the steps are as follows:

[0036](1) The preparation of thiourea: pour into the reaction kettle the mixed liquor that an amount of mother liquor water I and tap water mix; Drop into 3,4-dichloroaniline after being warmed up to 90 ℃, throw and stir and make material fully dissolve, The dissolution temperature is 90°C; then add hydrochloric acid dropwise to the reaction kettle for the first time, and immediately put in ammonium thiocyanate aqueous solution after dropping, and immediately add the remaining hydrochloric acid; then raise the temperature to 100°C, keep warm for reaction, and cool to crystallize after the reaction; Blowing and filtering to obtain thiourea and mother liquor water I, washing thiourea with water to neutrality, and drying to obtain thiourea; the weight ratio of the 3,4-dichloroaniline, hydrochloric acid, and ammonium thiocyanate is 1: 1.0 : 0.7; The hydrochloric acid that drops for the firs...

Embodiment 3

[0040] Example 3. A preparation method for dispersing scarlet, the steps are as follows:

[0041] (1) The preparation of thiourea: pour into the reaction kettle the mixed liquor that an amount of mother liquor water I and tap water are mixed; Drop into 3,4-dichloroaniline after being warmed up to 75 ℃, throw and stir and make material fully dissolve, The dissolution temperature is 75°C; then add hydrochloric acid dropwise to the reaction kettle for the first time, immediately put in ammonium thiocyanate aqueous solution after dropping, and immediately add the remaining hydrochloric acid; then raise the temperature to 90°C, keep warm for reaction, and cool to crystallize after the reaction; Blowing and filtering to obtain thiourea and mother liquor water I, washing thiourea with water to neutrality, drying to obtain thiourea; the weight ratio of the 3,4-dichloroaniline, hydrochloric acid, ammonium thiocyanate is 1: 0.75 : 0.55; the hydrochloric acid that drops for the first ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com