Method for preparing double-epoxy modified biochip substrate

A technology of bis-epoxy and biochips, applied in biochemical equipment and methods, measurement/inspection of microorganisms, instruments, etc., can solve the problems of not improving the binding force and detection signal strength, and achieve simple preparation methods Easy to operate, regular spotting, and strong binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

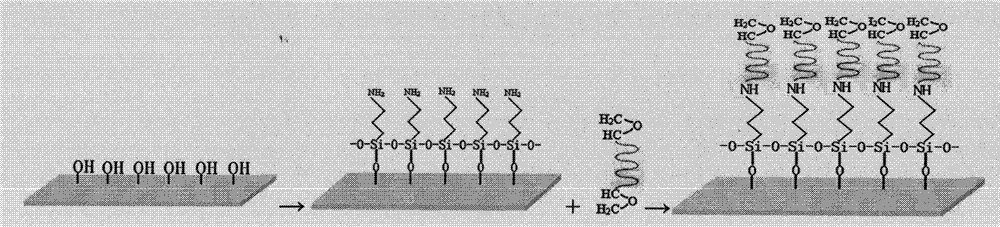

Method used

Image

Examples

Embodiment 1

[0024] (1) Measure 115.7ml of 99.8% absolute ethanol, 7.5ml of silane coupling agent, and 1.8ml of glacial acetic acid into a three-necked flask, and stir magnetically for 60 minutes at room temperature.

[0025] (2) Put the glass piece into a dyeing jar filled with ultrapure water and ultrasonically for 10 minutes, wash it twice with ultrapure water, and then soak it in concentrated sulfuric acid, hydrogen peroxide and ultrapure water (volume ratio is 4:1:20 ) in a mixed solution of 130°C for 30 minutes, cooled, rinsed 3 times with ultrapure water; then immersed in a mixed solution of concentrated hydrochloric acid and ethanol (1:1 by volume) for 24 hours, Wash with ultrapure water 5 times, dry at 110°C for 30 minutes, and cool to room temperature.

[0026] (3) Put the surface-treated glass sheet into the aminosilane coupling agent solution, then put it into a constant temperature and humidity box, control the relative humidity at 50%, set the temperature at 30°C, and place i...

Embodiment 2

[0029] (1) Measure 122.5ml of 99.8% absolute ethanol, 1.9ml of silane coupling agent, and 0.5ml of glacial acetic acid into a three-necked flask, and stir magnetically at room temperature for 90 minutes.

[0030] (2) Put the glass piece into a dyeing jar filled with ultrapure water and ultrasonically for 5 minutes, wash it twice with ultrapure water, and then soak it in concentrated sulfuric acid, hydrogen peroxide and ultrapure water (volume ratio is 4:1:20 ) in a mixed solution of 80°C for 60 minutes, cooled, rinsed 3 times with ultrapure water; then soaked in a mixed solution of concentrated hydrochloric acid and ethanol (1:1 by volume) for 3 hours, Wash with ultrapure water three times, dry at 140°C for 15 minutes, and cool to room temperature.

[0031] (3) Put the surface-treated glass sheet into the aminosilane coupling agent solution, then put it into a constant temperature and humidity box, control the relative humidity at 30%, set the temperature at 25°C, and place it...

Embodiment 3

[0034] Detection of Immobilization Ability of Diepoxide-Modified Biochip Substrate

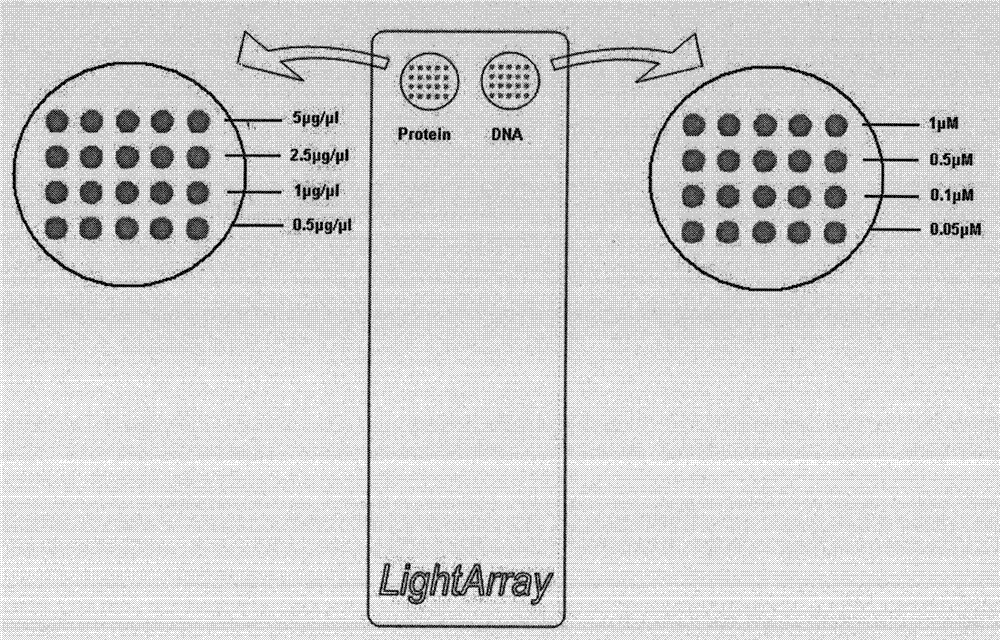

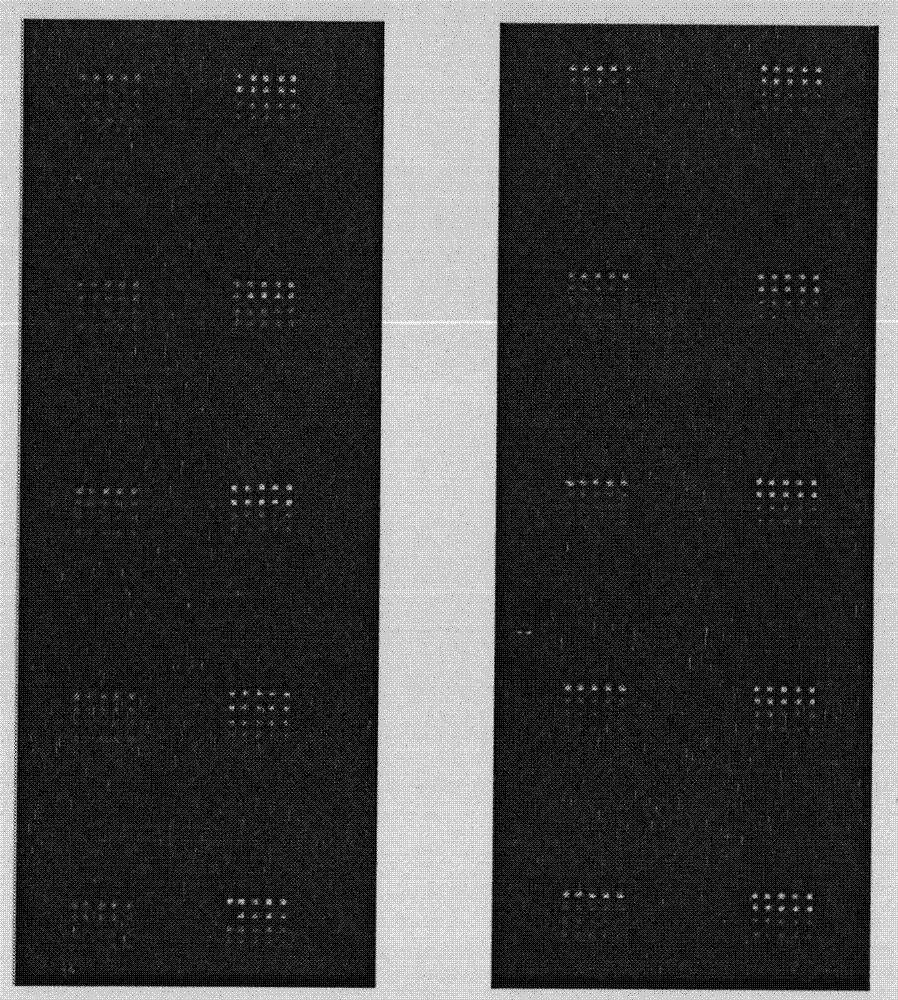

[0035] The biochip substrate modified by the double epoxy group used in this example was prepared according to the method described in Example 1, and this example was obtained by Arrayit 2. The spotting instrument performs spotting test on the epoxy substrate, and the schematic diagram of spotting matrix design is as follows: figure 2 shown, and then through the Axon 4000B: Cy3 PMT600, Power100 scanner detects its fluorescence signal intensity to reflect the immobilization ability of the bis-epoxy modified biochip substrate, the specific operation is as follows:

[0036] (1) Prepare samples for spotting

[0037] a. At room temperature, add DNA probes to 50% DMSO / 50% H 2 O buffer. Add antibody probes to 20% glycerol / 80% H 2 O buffer;

[0038] b. Transfer the sample to a 96-well plate or a 384-well plate according to the schematic diagram of the matrix design, tap the microplate to make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com