Water injection type high-pressure combustion method for air distribution machine pipeline

A combustion method and air distribution technology, which are used in burners, earth-moving drilling, mining fluids, etc., can solve the problems of shortened service life (sometimes less than one working day of gas injection, prone to bursting, denudation, difficult practical application, etc. , to achieve the effect of prolonging the continuous work cycle, improving work stability and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

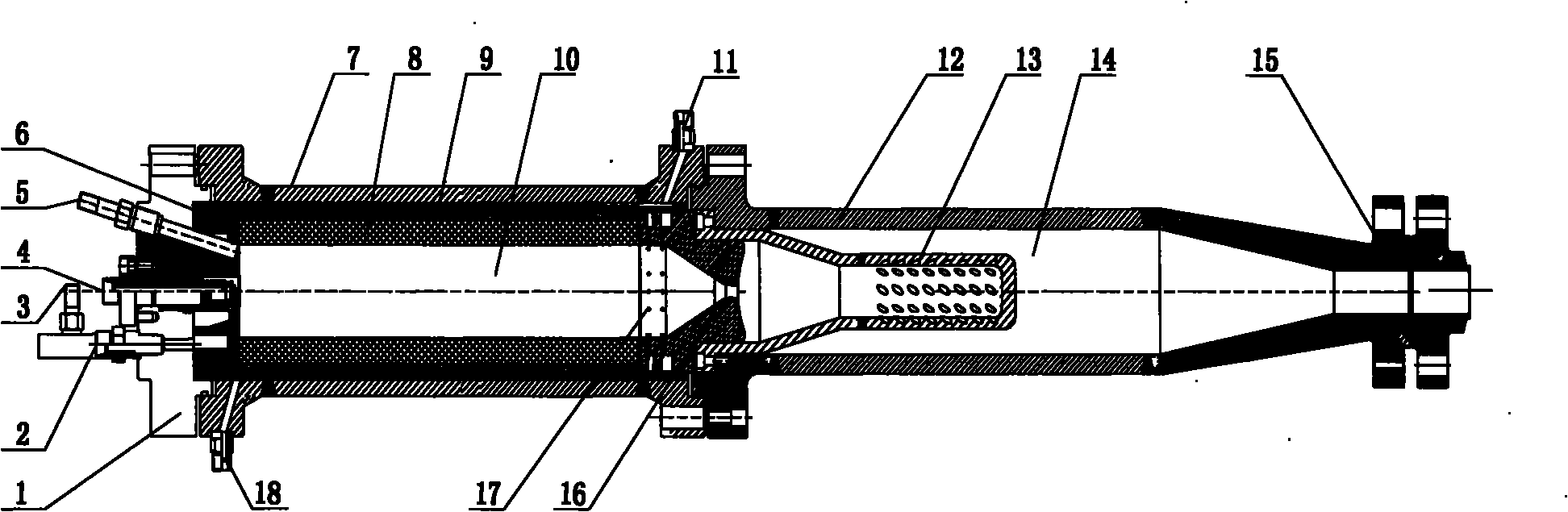

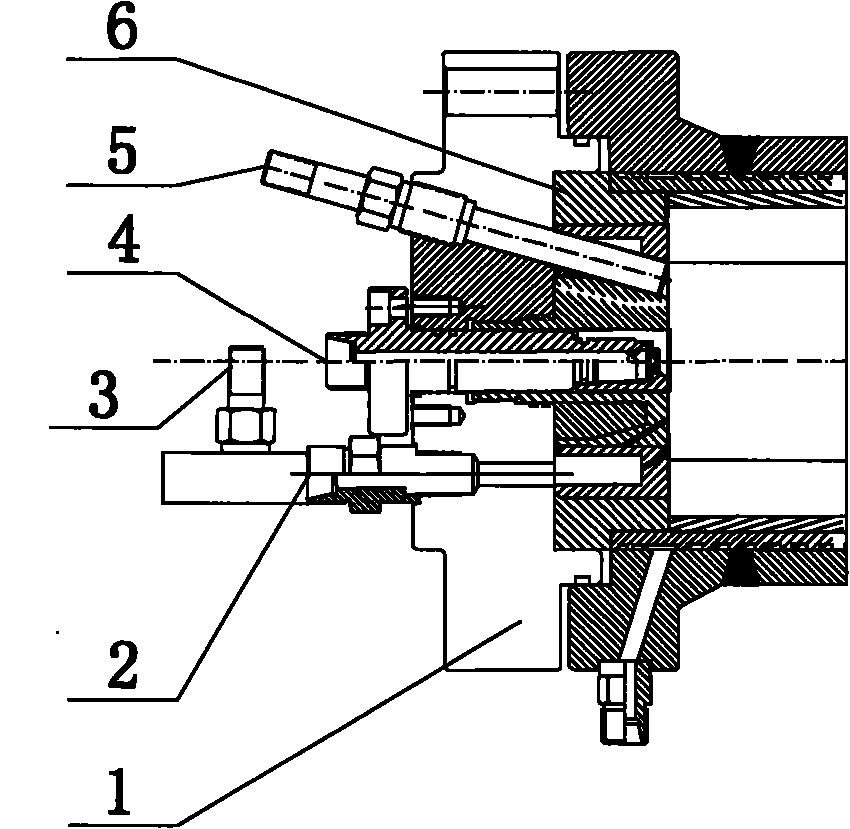

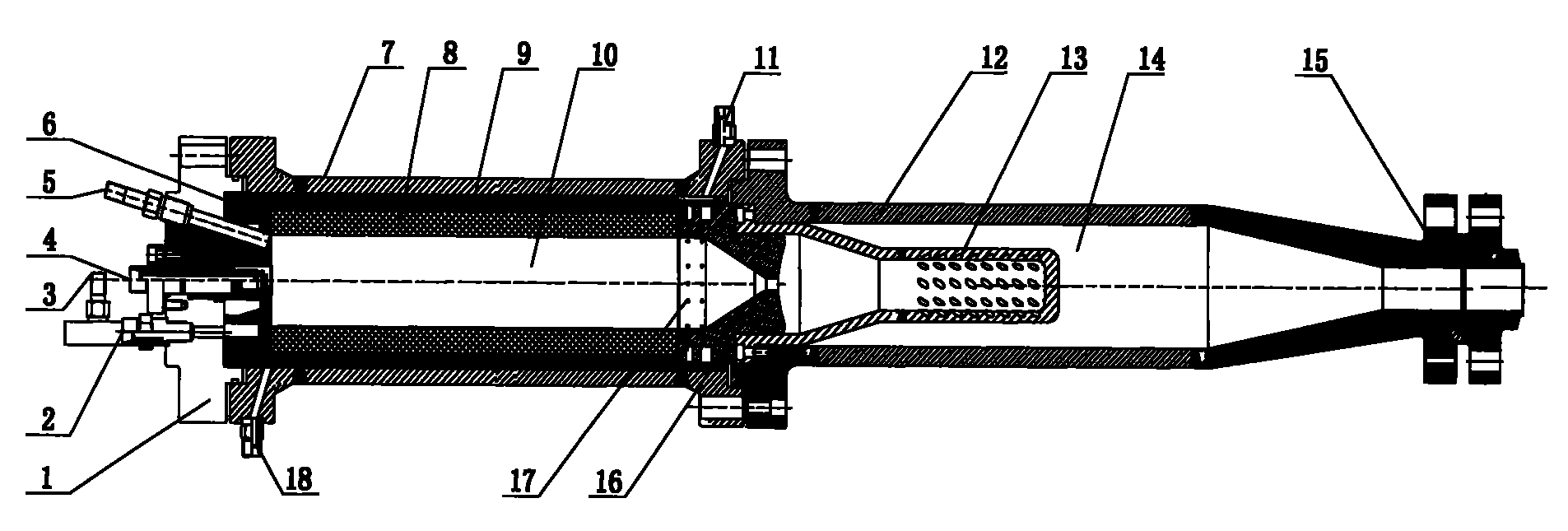

[0028] Example: such as figure 1 As shown, the air distribution device pipeline water injection type high-pressure combustion method provided by the present invention is to set a water injection port 3 on the air distribution device 2 pipeline of the burner head 1, and inject a certain amount of water. The injected water and the combustion air ( That is, the air that enters the burner from the air distributor) is sprayed into the combustion chamber together, so that the temperature in the combustion chamber drops from about 2000°C to 1500-1600°C, thus ensuring the long-term safe and stable operation of the device. Fuel enters the combustion chamber 10 from the oil nozzle 4 , compressed air enters the combustion chamber 10 from the air distributor 2 , and the working end of the igniter 5 also leads to the combustion chamber 10 .

[0029] When this embodiment is working, the fuel and air enter the combustion chamber 10, atomize and mix, and are ignited by the igniter 5. After co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com