Full closed pipe type fire resistant flame retardant bus

A fire-resistant, flame-retardant, fully-enclosed technology, applied in the direction of single-tube conductors, power cables, electrical components, etc., can solve the problems of difficult to meet the requirements of bus heating and electric power, high production costs of rectangular bus panels, and insufficient bus transmission capacity, etc. problem, to achieve the effect of large surface area, good heat dissipation conditions and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

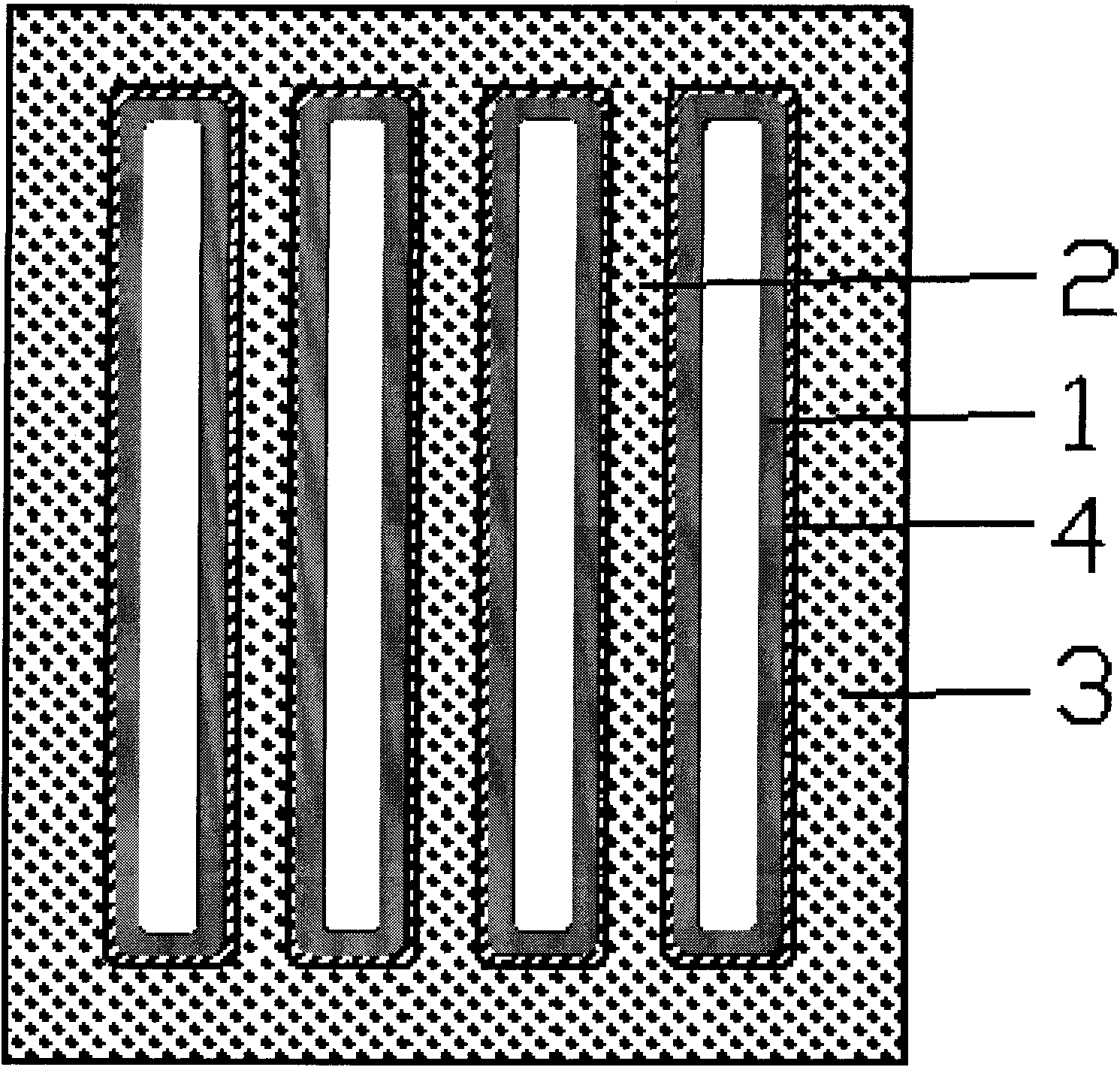

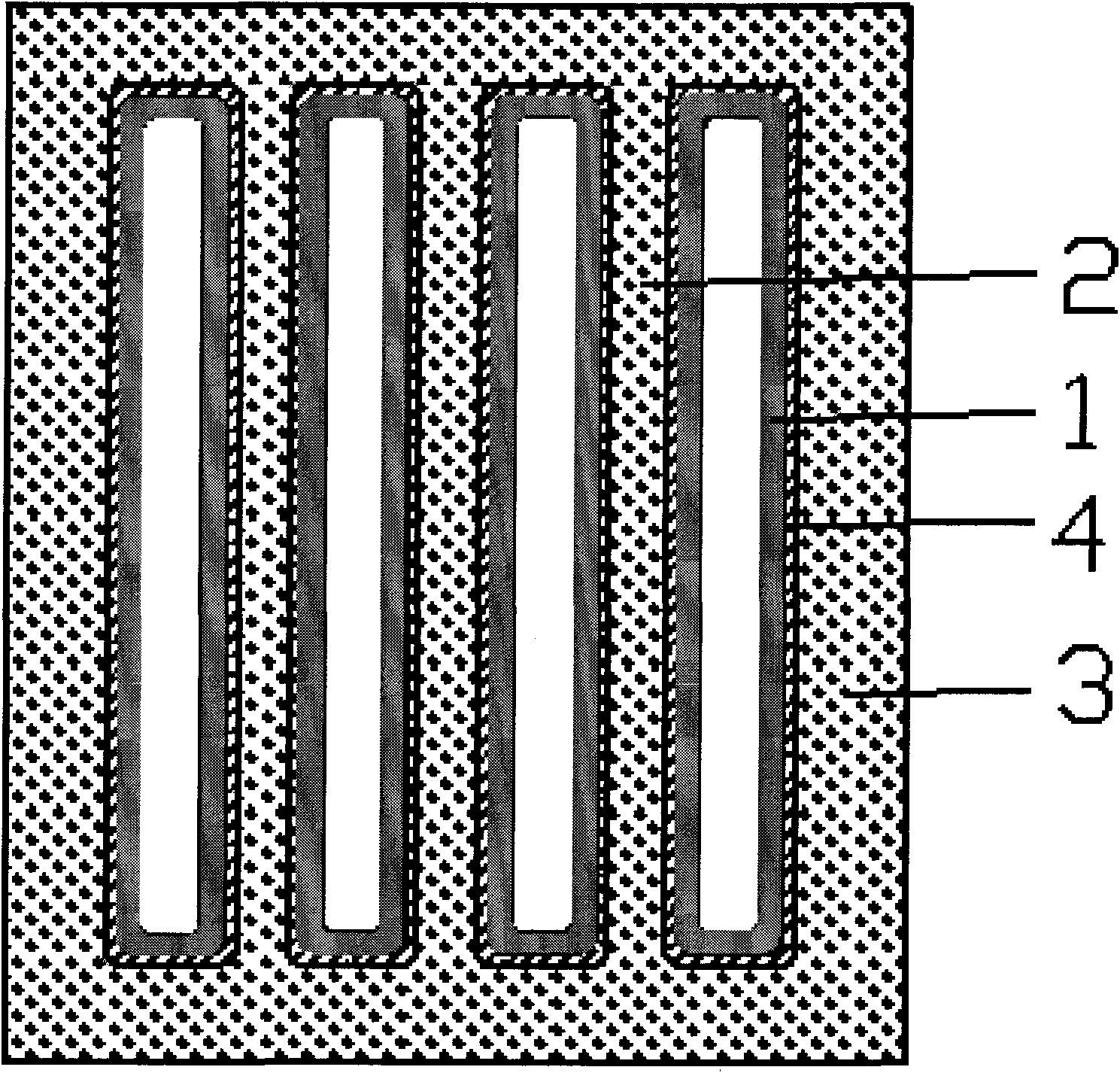

[0012] The technical solution of the present invention is described in detail below.

[0013] figure 1 It is a cross-sectional structure diagram of the fully enclosed tubular fire-resistant and flame-retardant busbar of the present invention. As shown in the figure, the electrical conductor 1 is made of a hollow metal tube. The metal material can be selected from copper, aluminum and other materials with good electrical conductivity and certain mechanical strength. The wall thickness of the metal pipe is 1 mm to 10 mm. The hollow metal tube is used as the conductor, the current density distribution on the conductor surface is uniform, the skin effect is low, and the heat dissipation condition is good, which can naturally form hot air convection, increase the surface area of the conductor, and the temperature rise of the busbar during operation is low.

[0014] The conductor is wrapped with mica tape, which can significantly improve the fire resistance of the conductor. Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com