Method for separating quinoline from coal and biomass coliquified oil product

A biomass and co-liquefaction technology, applied in the field of separation of quinoline, can solve the problems of pollution, many steps, loss of other substances in coal tar, etc., and achieves the effects of low operating cost, simple process and easy industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

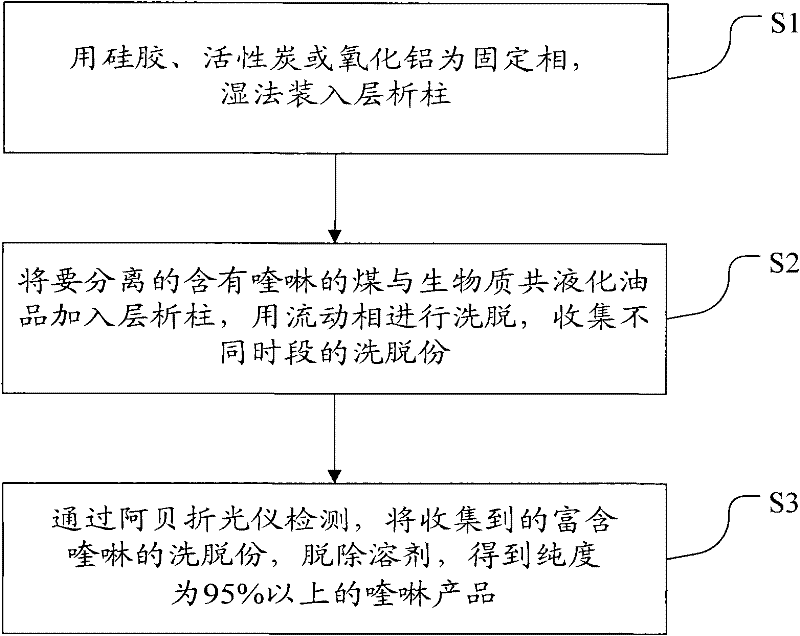

Method used

Image

Examples

example 1

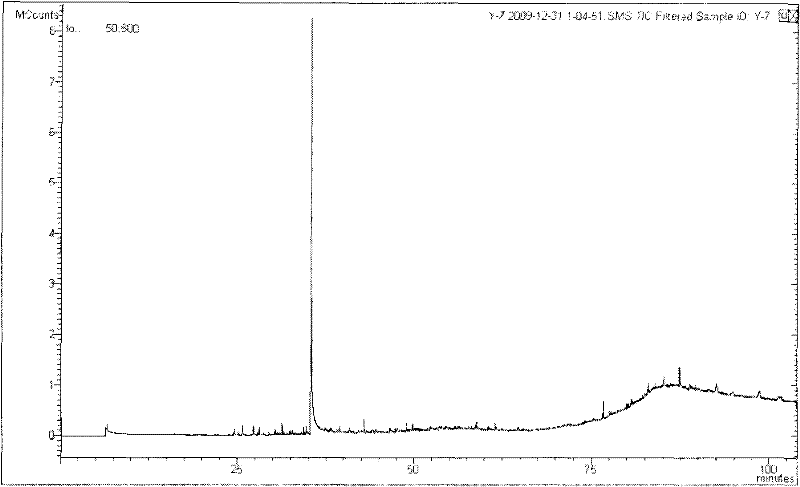

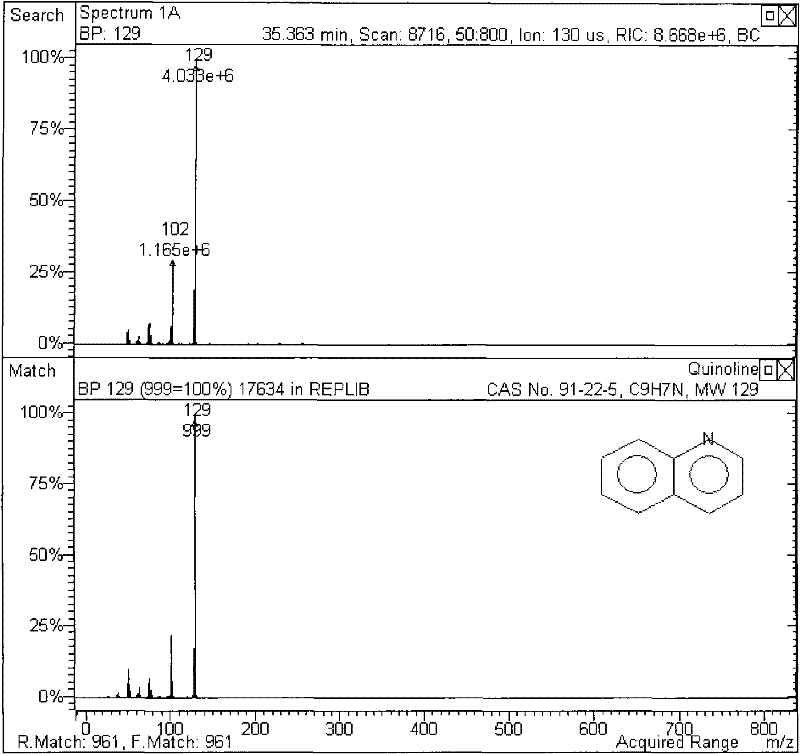

[0028] Weigh 60g of activated silica gel, use n-hexane as a solvent, and load it into a chromatography column by wet method; weigh 2.0896g of Shenhua coal and lignin co-liquefaction oil, load it by wet method, and perform column chromatography; Methane, chloroform, ethanol or methanol are mobile phases, detected by Abbe's refractometer, and fractions are collected to obtain quinoline products with a purity of 96%.

example 2

[0030] Weigh 60g of activated alumina, use chloroform as a solvent, and load it into a chromatographic column by wet method; weigh 2.0237g of Shengli coal and lignin co-liquefaction oil, load it by wet method, and perform column chromatography; Dichloromethane, ethyl acetate, ethanol or methanol are mobile phases, detected by Abbe's refractometer, and fractions are collected to obtain quinoline products with a purity of 98%.

example 3

[0032] Weigh 30g of activated silica gel, use n-hexane as a solvent, and load it into a chromatographic column by wet method; weigh 1.1096g of Shenhua coal and sawdust co-liquefied oil, load it by wet method, and perform column chromatography; , chloroform, ethanol or methanol as the mobile phase, detected by Abbe's refractometer, and collecting fractions to obtain the quinoline product with a purity of 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com