PVC plastic-wood material

A technology for wood-plastic materials and wood powder, applied in the field of PVC-wood-plastic materials, can solve the problems of poor system compatibility, decreased product strength, uneven appearance, etc., and achieve the effect of increasing the amount of wood powder, smooth appearance and large dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

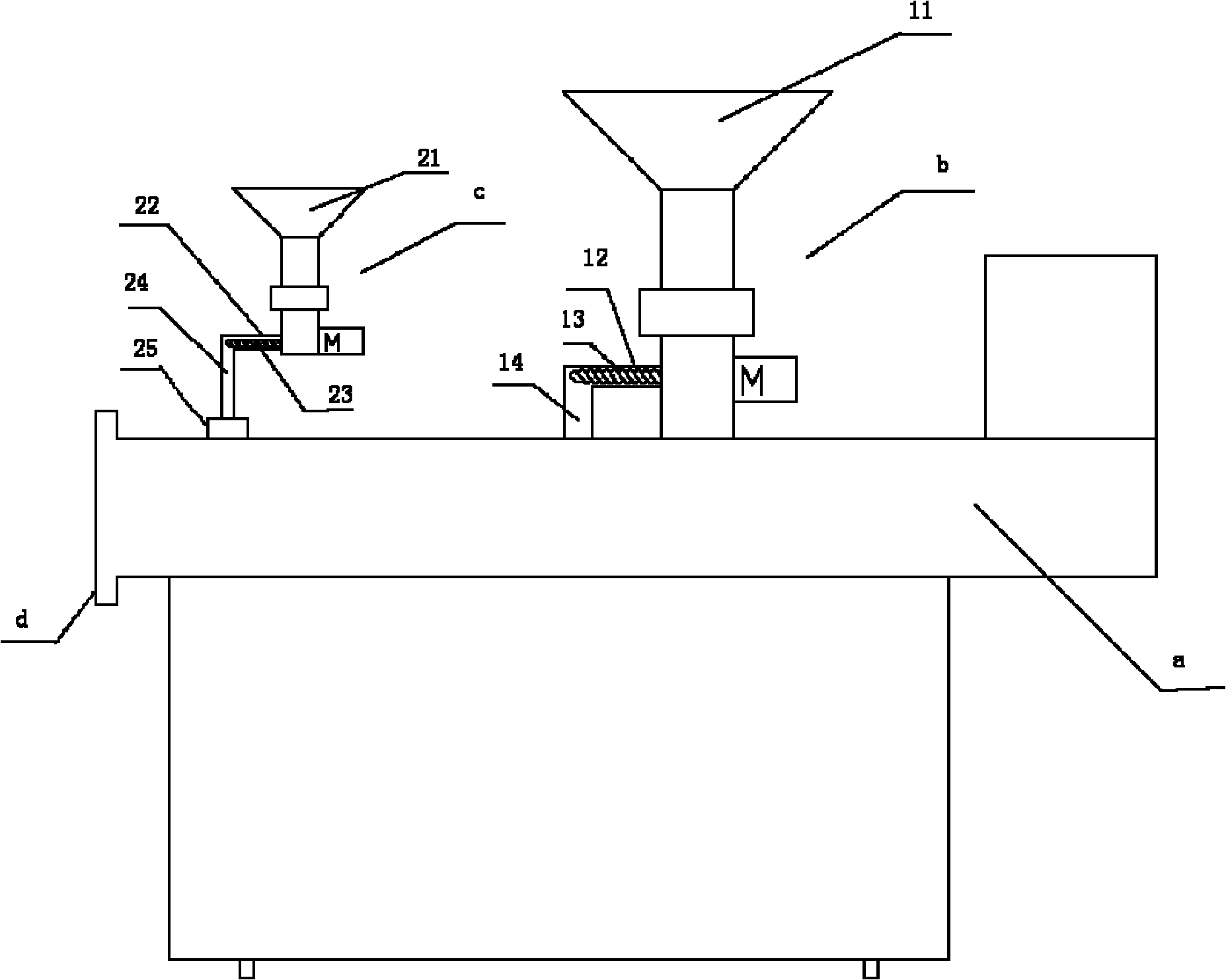

Image

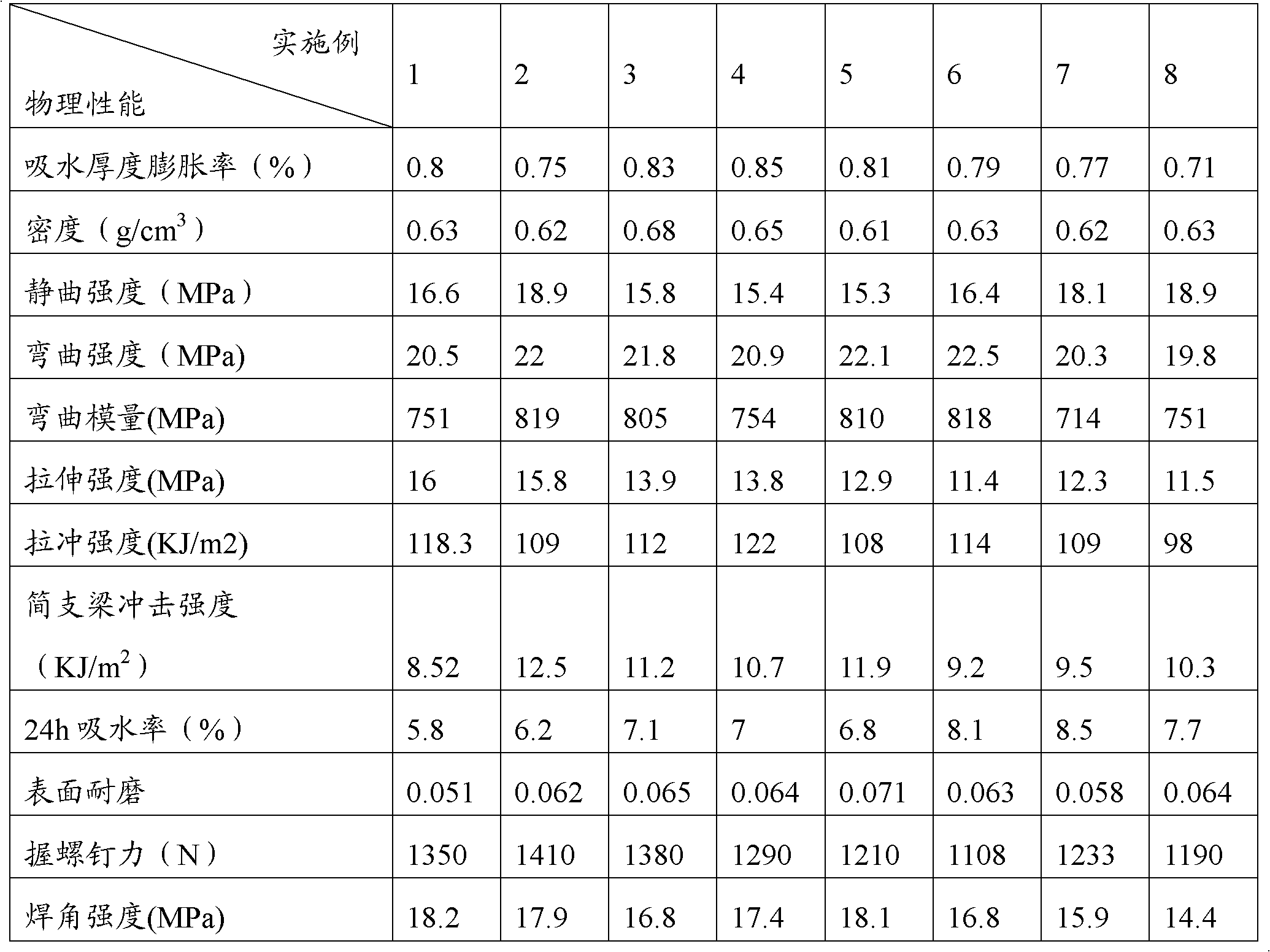

Examples

Embodiment Construction

[0035] The preferred embodiments are cited below, and the present invention is described in detail as follows.

[0036] The raw material that following embodiment adopts is:

[0037] PVC: produced by Qilu Petrochemical Company, brand SG-8;

[0038] CPE: Produced by Jiangsu Tianteng Chemical Co., Ltd., brand CPE135;

[0039] Titanate coupling agent: produced by Shanghai Nuotai Chemical Co., Ltd., brand LH-22;

[0040] Wood powder: moisture content is 1%, fineness is 30 mesh;

[0041] Wood grain masterbatch: produced by Guangdong Changsheng Chemical Co., Ltd., brand F38.

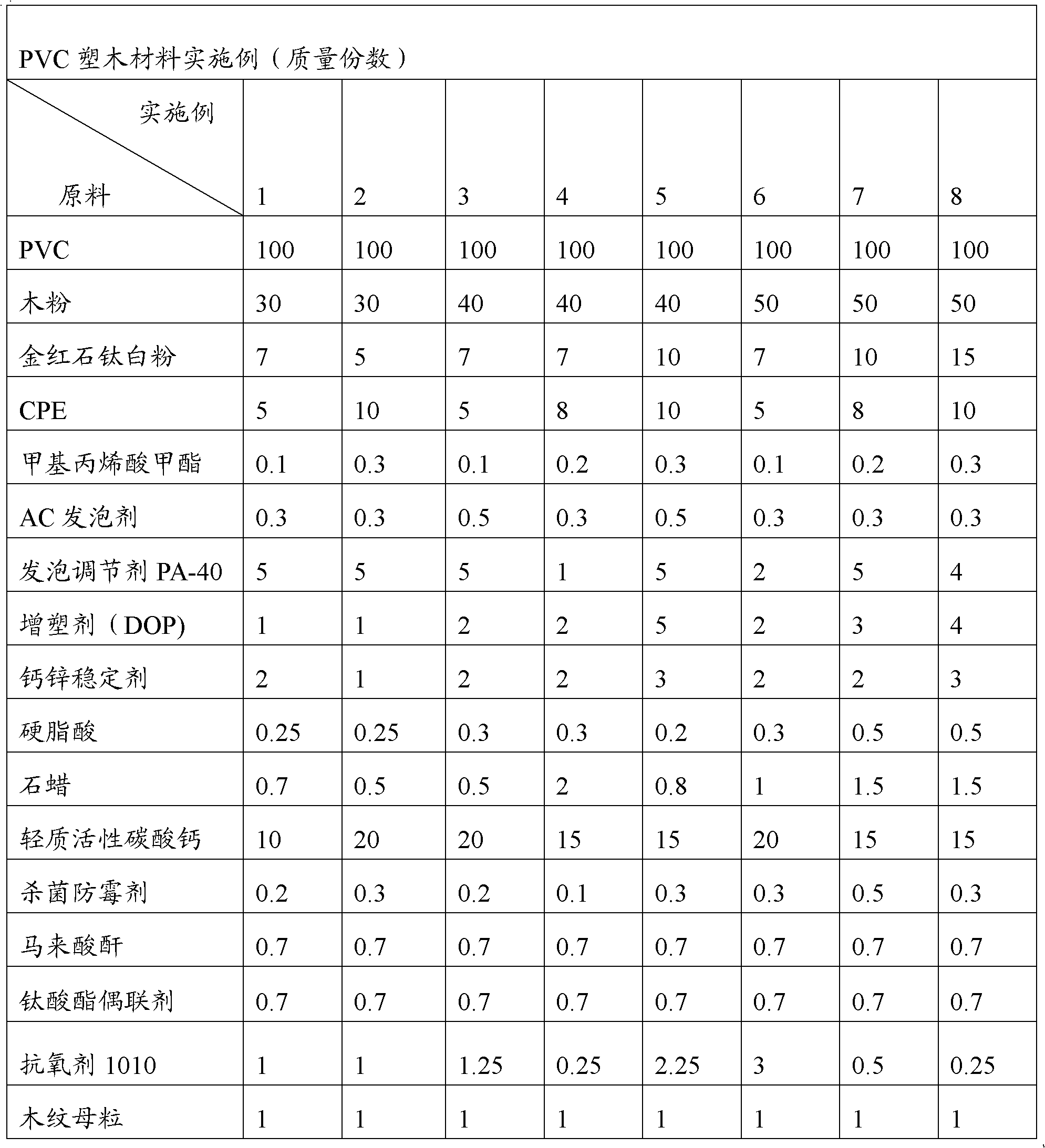

[0042] The used proportioning of embodiment is as shown in table 1:

[0043] Table 1

[0044]

[0045] The production steps in each of the above-mentioned embodiments include:

[0046] 1) Add wood flour and maleic anhydride to a drier and dry for 1-2 hours. The temperature of the drier is set at 70-100°C. After drying, the moisture content of the wood flour is lower than 0.5%.

[0047] 2) Stir PVC, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com