Preparation method capable of improving fermentation yield of tautomycin

An allosteric and yield technology is applied in the field of preparation for improving the fermentative yield of allostericin, can solve problems such as cell dissolution and death, and achieves the effects of convenient operation, increased yield, and improvement of low yield of allostericin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Strain: Streptomyces spiroverticillatus, the preservation number is CGMCC-0092.

[0029] The culture medium formula of the embodiment of the invention:

[0030] Slant medium: the slant medium is Gao's No. 1 medium;

[0031] Seed medium: glucose 10g / L, beef extract 5g / L, yeast powder 10g / L, NaCl 2g / L, K 2 HPO 4 0.02g / L, initial pH 6.5; solvent is water.

[0032] Fermentation medium: glucose 20g / L, soybean powder 25g / L, starch 10g / L, yeast extract 5g / L, NaCl 2g / L, K 2 HPO 4 0.05g / L Initial pH 6.5; solvent is water.

[0033] experiment procedure:

[0034] Step 1: Seed Culture

[0035] The S. spiroverticillatus strain was inserted into a 500ml Erlenmeyer flask containing 100ml of seed medium from a slant, and cultured in a rotary shaker at 28°C for 24h with a rotation speed of 150rpm.

[0036] Step 2: Effect of maleic anhydride at different pH on fed-fed fermentation

[0037] Transfer 3ml of seed solution into a conical flask containing 50ml of fermentation medium...

Embodiment 2

[0043] Bacterial classification, substratum and culture condition are with example 1

[0044] experiment procedure:

[0045] Step 1: Seed cultivation is the same as example 1

[0046] Step 2: Add maleic anhydride at different times

[0047] Transfer 6ml of seed solution to a conical flask containing 100ml of fermentation medium, and carry out fermentation at a temperature of 28°C and a rotation speed of 150rpm. After it was fermented for a certain period of time, precursor substances were added. There were eight experiments in total. Each experiment consisted of three parallel experiments. The average value of the three parallel experiments was taken as the following results.

[0048] In order to determine the best time for maleic anhydride to add, add 0.2% (g / mL) maleic anhydride in different fermentation time periods respectively, the concentration is 40g / L, add maleic anhydride The amount of the aqueous solution was 5 mL, and the control group was distilled water, and 5 ...

Embodiment 3

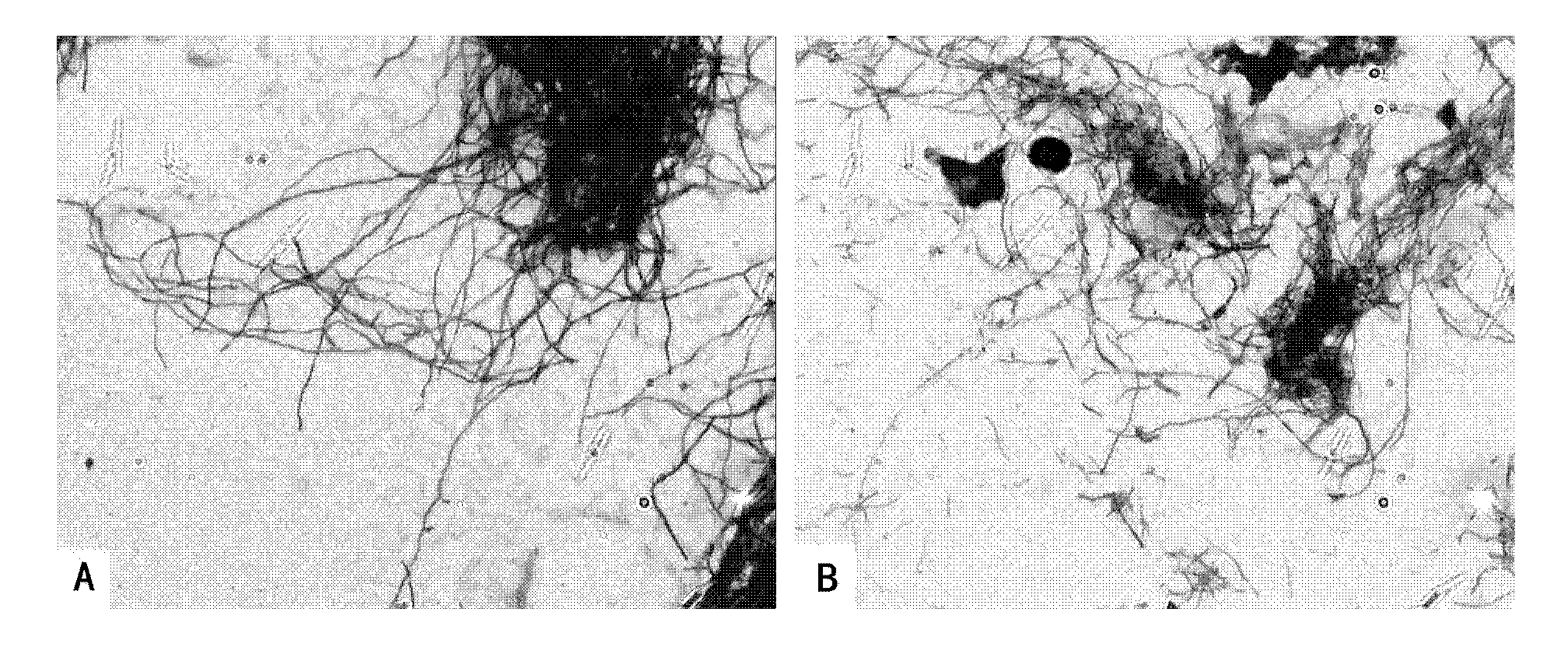

[0055] It has been clarified in Example 1 that the addition of maleic anhydride must be added in the form of its anhydride, and its pH must not be adjusted to be neutral or alkaline. Therefore, the added maleic anhydride is an acidic aqueous solution, which greatly affects the pH of the fermentation broth itself. Adding too much concentration or too fast will cause the pH of the fermentation broth to drop sharply, which will eventually affect the production of mutamycin. In order to further clarify the degree of influence of pH on mycelia and the optimum supplementary time and supplementary speed of maleic anhydride, we added before and after (B) maleic anhydride in Example 1 and under different pH conditions The mycelia were observed microscopically. The result is as figure 1 shown.

[0056] Experimental results

[0057] Before adding maleic anhydride, the pH of the fermented liquid was 6.5. At this time, the growth of mycelia was long and strong, and the fermented liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com