Safety syringe

A safety syringe and syringe technology, which is applied in the field of medical devices, can solve the problems such as the inability of the needle tip to be fixed, non-compliant, unsafe hidden dangers, etc., and achieve the effects of avoiding infection and disease transmission, easy to accept use, and reliable safety protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

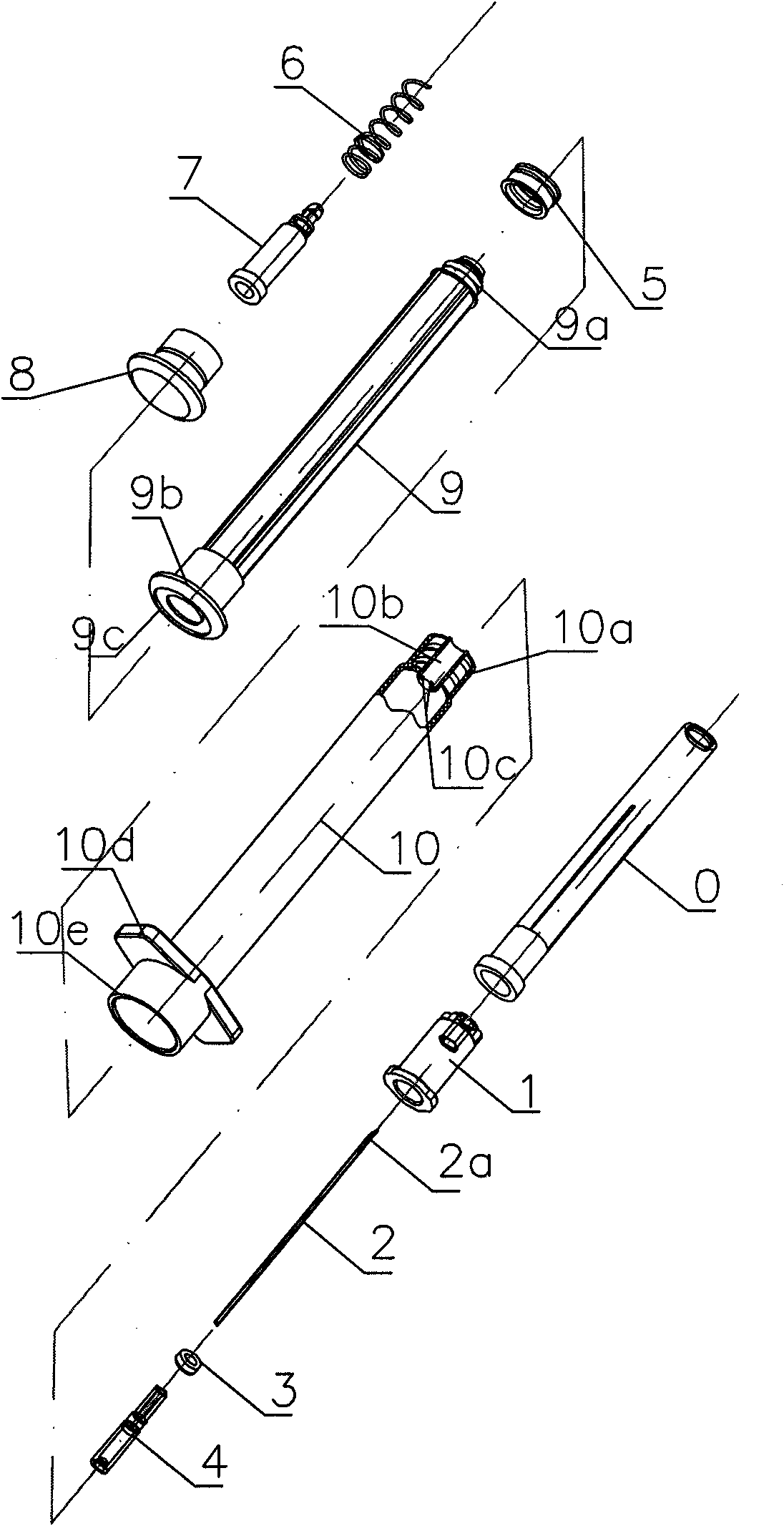

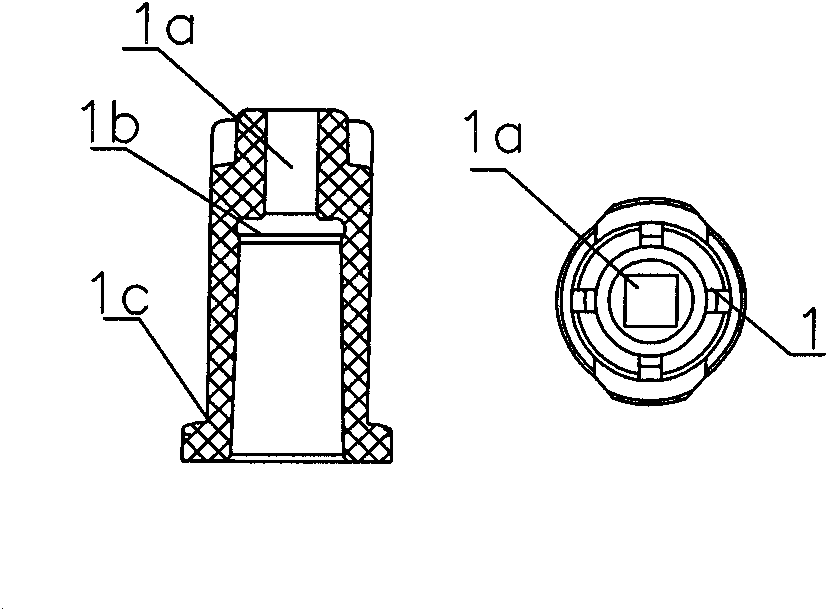

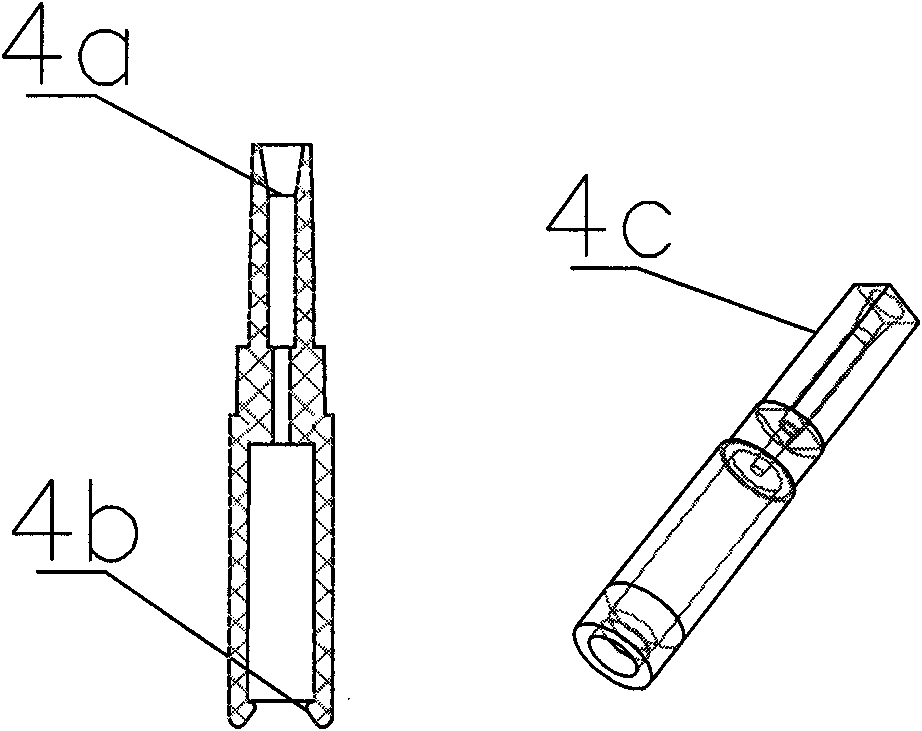

[0027] Depend on figure 1 It can be seen that a safety syringe of the present invention is composed of: needle point sheath 0, outer needle seat 1, needle tube 2, sealing ring 3, inner needle seat 4, piston 5, spring 6, latch 7, end plug 8, push rod 9, The outer cylinder 10 is collectively composed. Sheath 0, outer needle hub 1, needle tube 2, sealing ring 3, and inner needle hub 4 are common injection needle components; sheath 0 is usually set on the outer surface of outer needle hub 1 to protect the needle tip from collision damage, and the front end of needle tube 2 has a sharp edge 2a; the sealing ring 3 is made of elastic plastic material, which acts as a friction seal between the inner and outer needle seats; the inner needle seat 4 has a hole in the center, and the needle tube 2 can be bonded in the hole, the lower half of the inner needle seat 4 is hollow, and the lower end There is a ring-shaped protrusion on the inner edge, and the outer edge of the upper half of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com