Plasma etching method for showing defect of cadmium zinc telluride infrared substrate

A plasma and cadmium zinc telluride technology, which is applied in semiconductor devices, sustainable manufacturing/processing, electrical components, etc., can solve the problems of uncontrollable corrosion depth and fuzzy contour water chestnut, and achieve the effect of enhancing precise controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

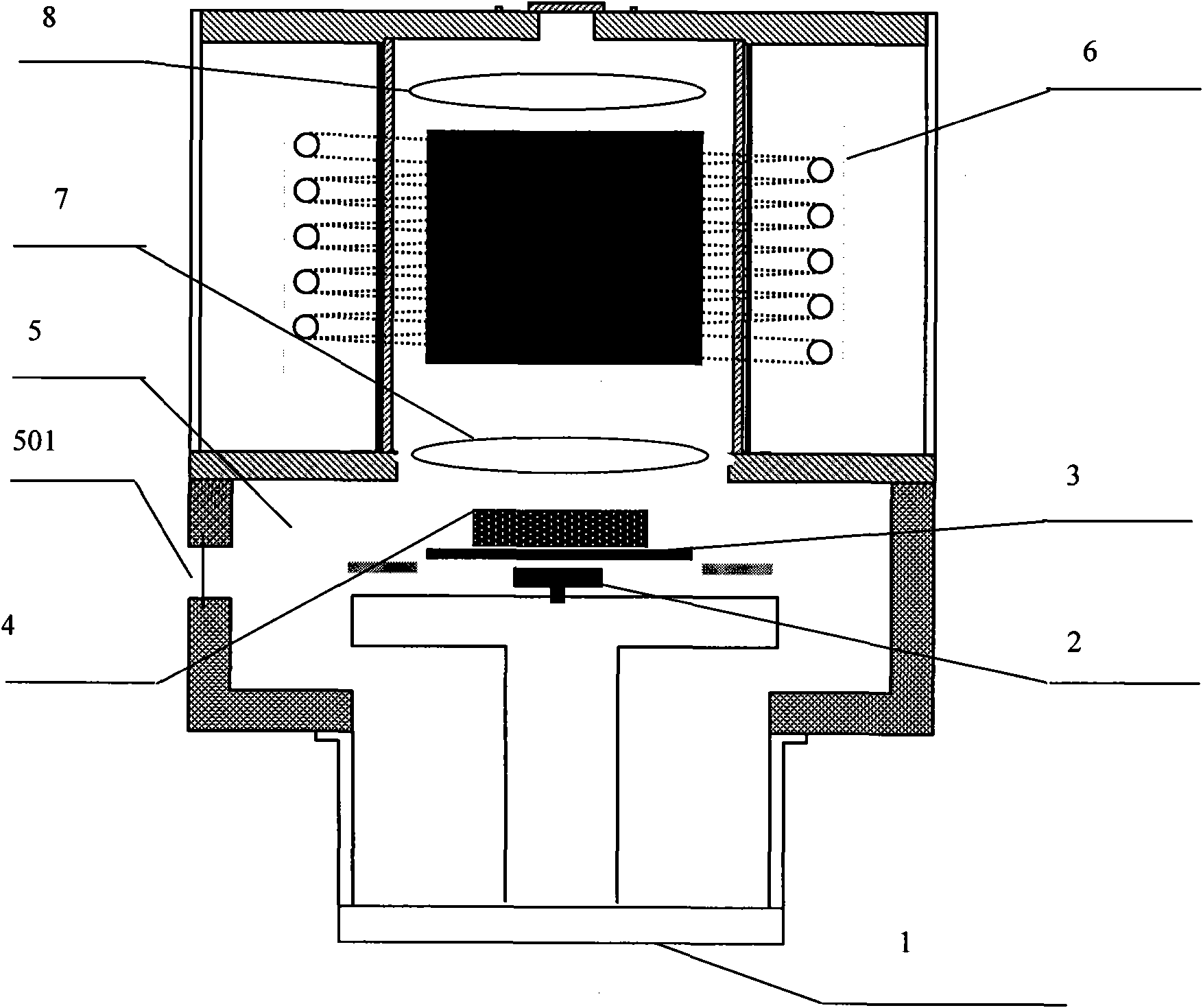

[0017] See figure 1 , the present invention uses British OXFORD company model to be the ICP enhanced RIE equipment of ICP65-80Plus. The equipment includes: a cavity 5 with a vacuum system 1, an RF source 2 for controlling plasma etching energy is placed in the cavity from bottom to top, a sample stage 3 with a temperature control system, and a lower intake coil 7 to generate plasma Body concentration RF source 6, upper intake coil 8. During etching, the etching sample 4 is fixed on the temperature-controlled sample stage 3 , and the etching situation of the sample can be observed in real time through the observation window 501 .

[0018] We take Cd 1-x Zn x Te (x=0.04) epitaxial material is a sample, and the method of the present invention is described in further detail:

[0019] A. Sample cleaning: The CZT substrate sample 4 was cleaned in three organic solvents of trichlorethylene, acetone and alcohol at 65° C. respectively.

[0020] B. Use vacuum grease to paste the CZ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Etching power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com