Flexible electromagnetic coupling torque transmission method for electric automobile

A technology of torque transmission and electromagnetic coupling, applied in the field of modern transportation, can solve problems such as slow response speed, achieve fast response speed, protect power source, and solve the problems of frictional heat generation and mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

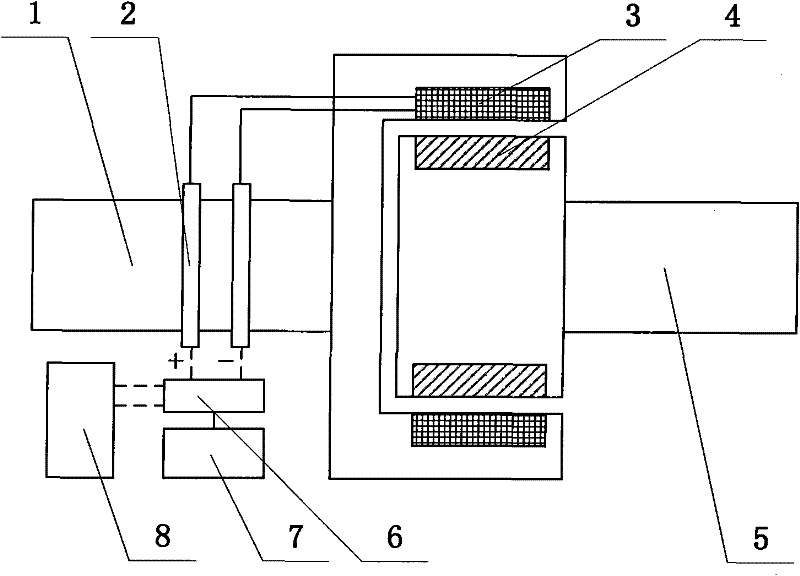

[0015] Such as figure 1 Shown, the present invention is made up of two parts of mechanical structure and electronic control system. The mechanical structure is composed of outer rotor shaft 1, slip ring 2, outer rotor excitation winding 3, inner rotor permanent magnet 4 and inner rotor shaft 5; the electronic control system is composed of drive module 6, control module 7 and power module 8. Among them, the outer rotor shaft 1 is rigidly connected with the output shaft of the electric vehicle drive motor as the power input shaft; the electronic control system provides excitation current to the outer rotor excitation winding 3 through the slip ring 2; the magnetic field generated by the excitation winding and the inner rotor permanent magnet The magnetic field of 4 interacts to transmit torque; the inner rotor shaft 5 is rigidly connected to the transmission input shaft as a power output shaft; the control module 7 collects parameter information such as current vehicle speed and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com