Catalyst for preparing methane by low-temperature oxidization of methane and preparation method and application thereof

A methane oxidation and catalyst technology, which is applied in the direction of oxidation reaction preparation, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problems of needing ultraviolet light source and low methane conversion rate, etc., and achieve simple reaction system, low energy consumption, and single type Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

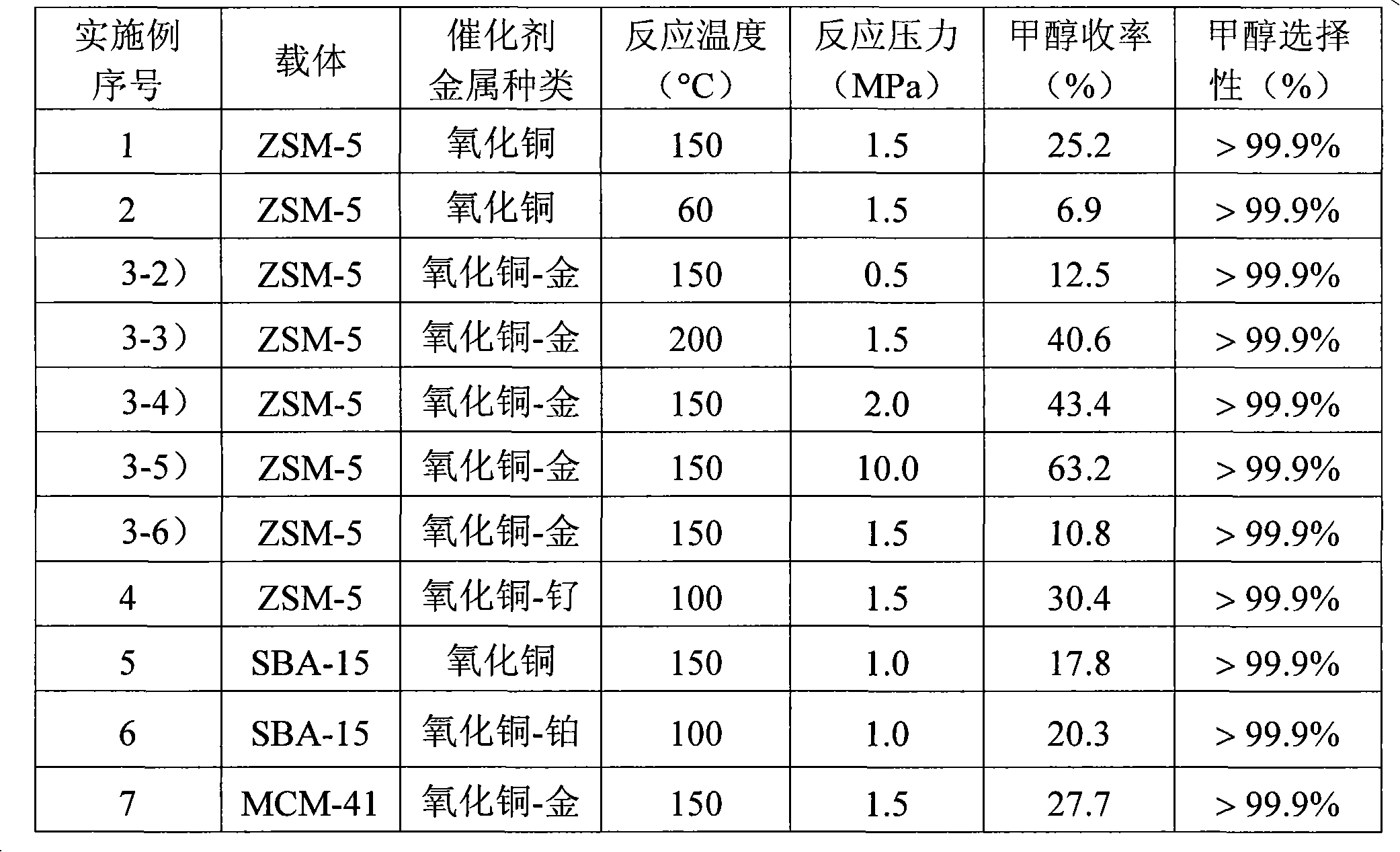

Examples

Embodiment 1

[0031] Embodiment 1, take copper oxide as the catalyst and catalytic effect of active component

[0032] 1) Dissolve copper acetate in distilled water to obtain a concentration of 1.0×10 -2 mol / L solution, take 1g of sodium ion-exchanged ZSM-5 (Nankai University Catalyst Factory) and immerse in 35mL of the above solution, stir at room temperature for 24 hours, filter, and wash with deionized water. The obtained support was subjected to two processes of solution immersion, stirring, filtering and washing, and finally the obtained support was dried in air and calcined at 110° C. for 24 hours to obtain Catalyst 1 . The mass ratio of molecular sieve to copper in the catalyst 1 is 100:2.1. The metal copper is supported on the molecular sieve in the form of copper oxide particles, and the average particle diameter of the copper oxide particles is 3.6 nm.

[0033]2) In a high-pressure reactor (1 L), the air mixture containing 4% methane was used as the reactant, and 0.1 g of Cataly...

Embodiment 2

[0034] Embodiment 2, take copper oxide as the catalyst and catalytic effect of active component

[0035] 1) Dissolve copper acetate in distilled water to obtain a concentration of 2×10 -2 mol / L solution, take 1g of ZSM-5 exchanged by sodium ion and immerse in 35mL of the above solution, stir at room temperature for 24 hours, filter and wash with deionized water. The obtained carrier went through two processes of solution impregnation, stirring, filtering and washing, and finally the obtained carrier was dried in air and calcined at 110° C. for 24 hours to obtain Catalyst 2 . The mass ratio of molecular sieve to copper in the catalyst 2 is 100:2.5. The metal copper is loaded on the molecular sieve in the form of copper oxide particles, and the average particle diameter of the copper oxide particles is 4.0 nm.

[0036] 2) In a high-pressure reactor (1 L), the reaction was carried out at 60° C. for 3 hours with 0.1 g of Catalyst 2 to catalyze methane oxidation with an air mixtu...

Embodiment 3

[0037] Embodiment 3, take copper oxide and gold as the catalyst of active component and catalytic effect

[0038] 1) Mix and dissolve copper acetate and chloroauric acid (the molar ratio of copper to gold is 4:1) in distilled water to obtain a copper ion concentration of 1×10 -2 mol / L and gold ion concentration is 2.5×10 -3 mol / L mixed solution, take 1g of sodium ion-exchanged ZSM-5 and immerse in the above solution, stir at room temperature for 24 hours, filter and wash. The obtained carrier went through two processes of solution immersion, stirring, filtering and washing, and finally the obtained carrier was dried in air and calcined at 110° C. for 24 hours to obtain Catalyst 3 . The mass ratio of molecular sieve, copper, and gold in the catalyst 3 is 100:1.9:0.1 in turn, and the copper and gold are loaded on the molecular sieve in the form of composite oxidation state nanoparticles, and the average particle diameter of the nanoparticles is 6.5 nm.

[0039] 2) In a high-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com