Purifying treatment method for industrial sewage

A technology for purification and treatment of industrial sewage, applied in the field of water treatment, can solve the problems of high chemical and operating costs, low utilization rate, poor operating effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

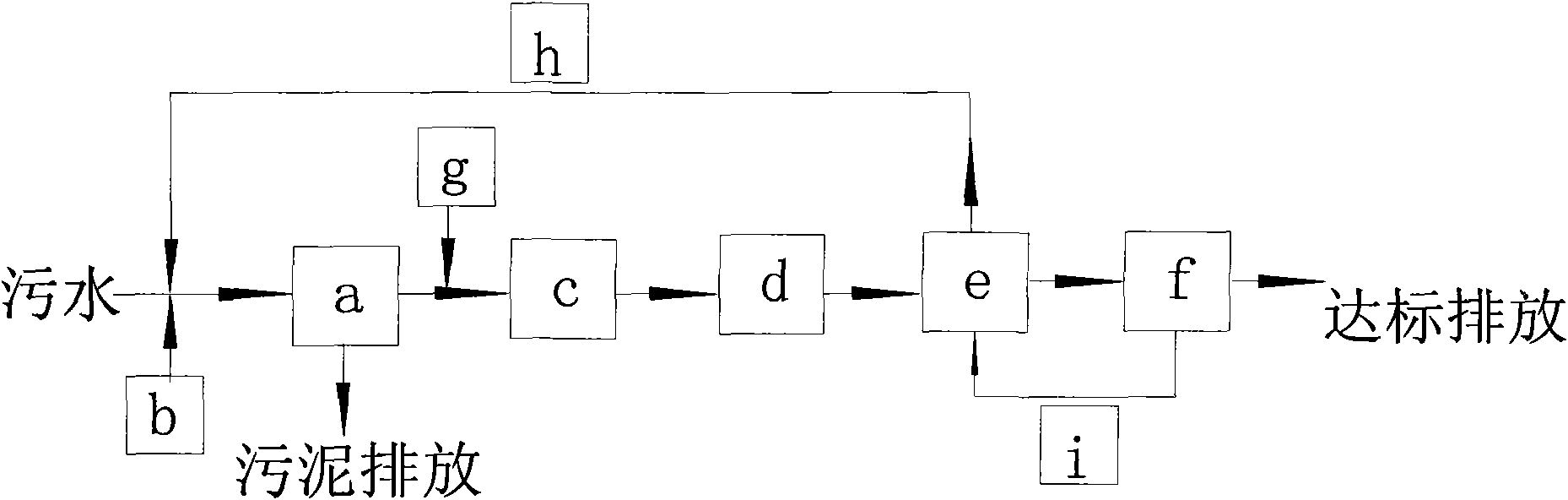

Method used

Image

Examples

Embodiment 1

[0026] The biochemically treated petrochemical wastewater with a COD of 270mg / L and ammonia nitrogen of 15mg / L is connected to this treatment process, and ferrous sulfate flocculant is added to the connected pipeline at an amount of 35mg / L, and the sewage is flocculated and precipitated Remove most of the suspended solids and colloids in the sewage, and reduce the COD in the sewage; after the sewage is clarified in the clarification (sedimentation) tank, it is connected to the photocatalytic oxidation tank by the pipeline for photocatalytic oxidation, before the sewage enters the photocatalytic oxidation tank Add H on the pipeline 2 o 2 Oxidant, H 2 o 2 The addition amount of the sewage is 60g / L; the residence time of the sewage in the photocatalytic oxidation tank is 0.6h, and the sewage enters the reduction pool after the photocatalytic oxidation reaction. In the reduction pool, there is an iron filings filter layer with a layer height of 0.3m. Excess H in the catalytic o...

Embodiment 2

[0028] The biochemically treated petrochemical wastewater with COD of 840mg / L and ammonia nitrogen of 55mg / L is connected to this treatment process, and ferrous sulfate flocculant is added to the connected pipeline with an addition amount of 200mg / L, and the sewage is flocculated and precipitated Remove most of the suspended solids and colloids in the sewage, and reduce the COD in the sewage; after the sewage is clarified in the clarification (sedimentation) tank, it is connected to the photocatalytic oxidation tank by the pipeline for photocatalytic oxidation, before the sewage enters the photocatalytic oxidation tank Add H on the pipeline 2 o 2 Oxidant, H 2 o 2 The addition amount of the sewage is 200g / L; the residence time of the sewage in the photocatalytic oxidation tank is 1.2h, and the sewage enters the reduction pool after the photocatalytic oxidation reaction. In the reduction pool, there is an iron filings filter layer with a layer height of 1.0m. Excess H in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com