Silicon slice-In2O3 flower-like nano structure compounded semiconductor material and preparation method thereof

A nanostructure and semiconductor technology, applied in the field of semiconductor materials and devices, and optoelectronic materials, can solve the problems of high cost and harsh preparation method conditions, and achieve the effect of low cost, simple method and lower requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] a. Clean the silicon wafer and cut it into 1.5cm×1.5cm pieces;

[0021] b. Heating the horizontal tubular growth furnace to 900°C at a rate of 5°C / min;

[0022] c. Mix 0.2g Sn powder, 2g In 2 o 3 Powder and 6g of C powder are mixed as a source and placed in a quartz boat, and a small piece of clean silicon wafer is covered on the quartz boat as a substrate to collect the reaction product. The vertical distance between the silicon wafer and the source is 4mm;

[0023] d. Put the quartz boat in the middle of the preheated horizontal tube furnace;

[0024] e. The inert gas Ar with a flow rate of 0.5L / min was introduced as a carrier gas, and the reaction was carried out at atmospheric pressure for 240 minutes;

[0025] f. Take out the quartz boat and the silicon chip, and a layer of light yellow substance grows on the silicon chip, which means the required material is obtained.

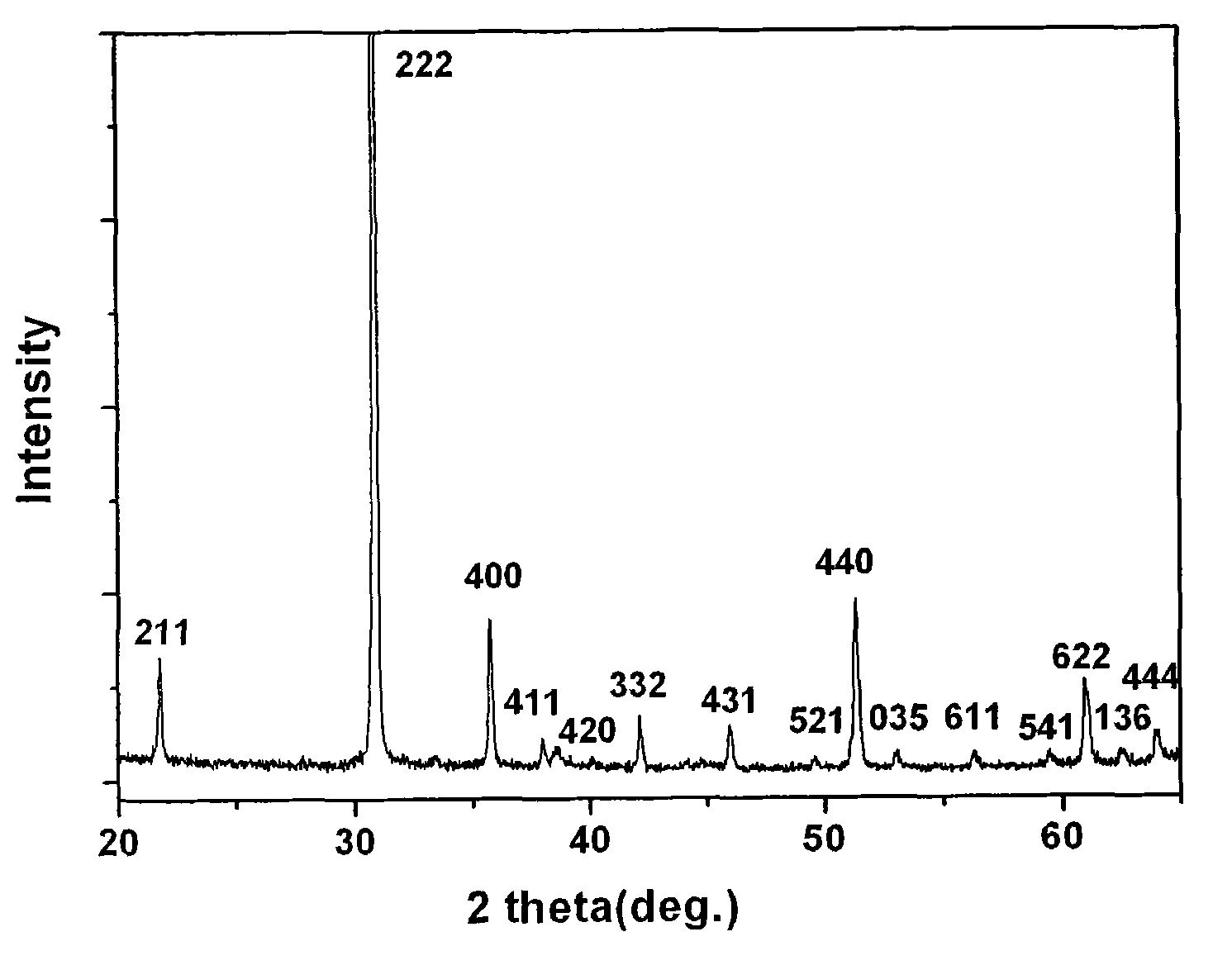

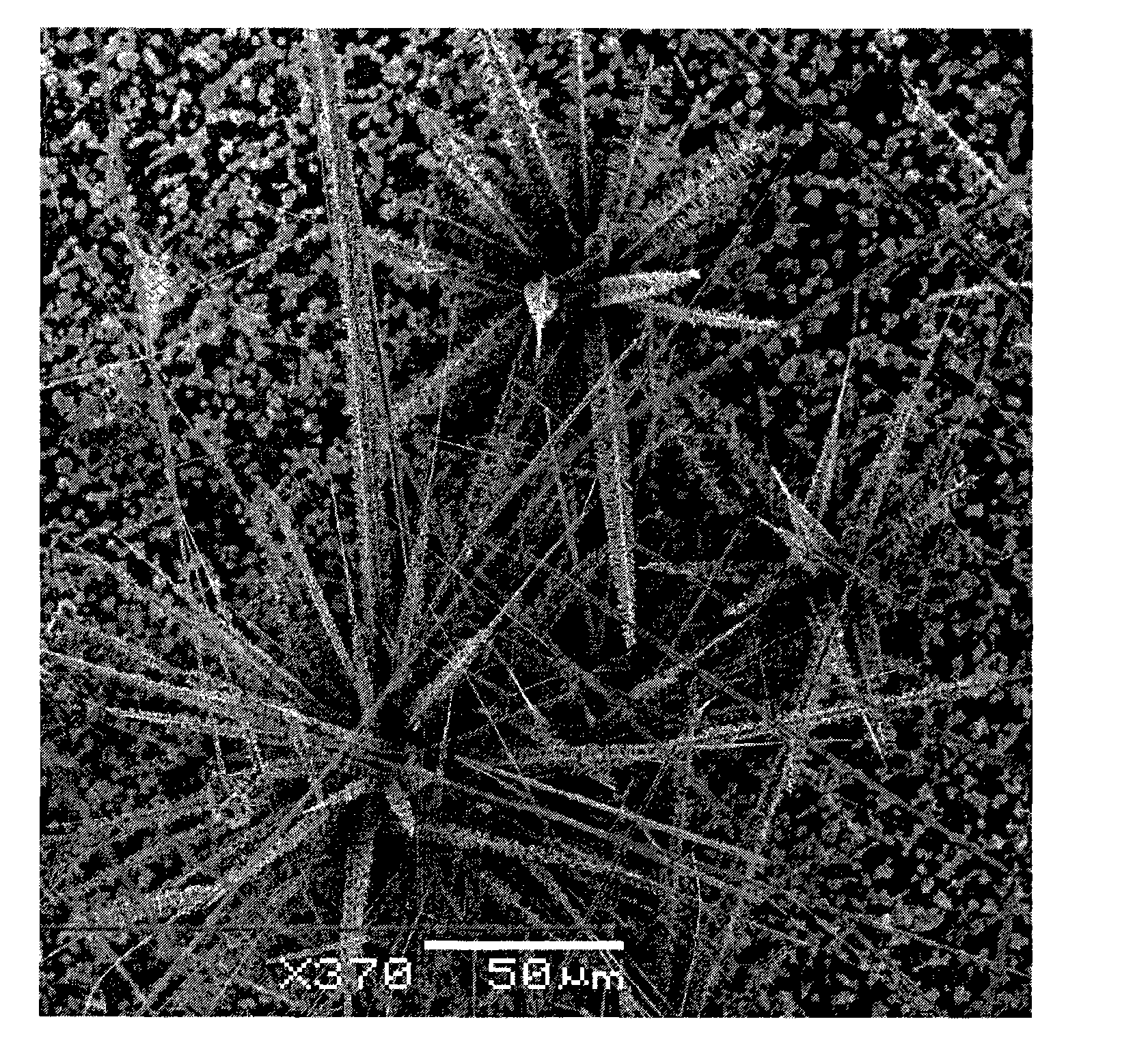

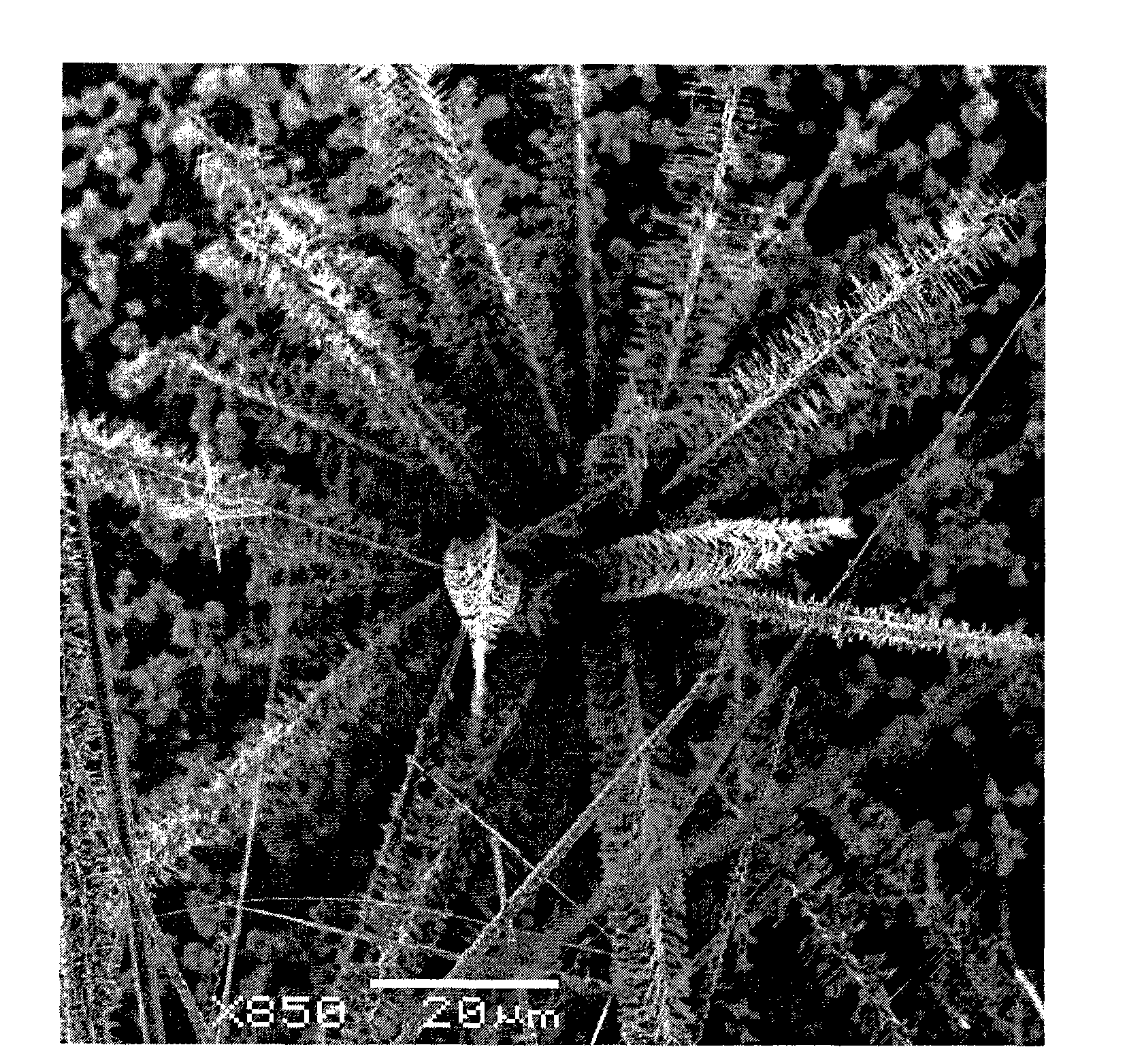

[0026] Detect the prepared material, and the test results are as follows: figure 1 , 2 , ...

Embodiment 2

[0028] a. Clean the silicon wafer and cut it into 1.8cm×1.8cm pieces;

[0029] b. Heating the horizontal tubular growth furnace to 850°C at a rate of 5°C / min;

[0030] c. Mix 0.1g Sn powder, 1g In 2 o 3 Powder and 3g of C powder are mixed as a source into a quartz boat, and a small piece of clean silicon wafer is covered on the quartz boat as a substrate to collect the reaction product. The vertical distance between the silicon wafer and the source is 5mm;

[0031] d. Put the quartz boat in the middle of the preheated horizontal tube furnace;

[0032] e. The inert gas Ar with a flow rate of 0.3L / min was introduced as a carrier gas, and the reaction was carried out at atmospheric pressure for 200 minutes;

[0033] f. Take out the quartz boat and the silicon chip, and a layer of light yellow substance grows on the silicon chip, which means the required material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com