Method for preparing polybenzimidazole/sulfonated polymer composite proton exchange membrane material

A technology of sulfonated polymer and polybenzimidazole, which is applied in the field of functional polymer material preparation, can solve the problem of insufficient and uniform dispersion of basic polymers, and achieve simple operation, uniform dispersion, alcohol resistance and temperature resistance Improved effect

Inactive Publication Date: 2010-11-03

TSINGHUA UNIV

View PDF0 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the difference in the main chain structure of the acid-base polymer, there is often the problem that the base polymer cannot be fully and uniformly dispersed in the acid-base polymer matrix

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

example 1

example 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

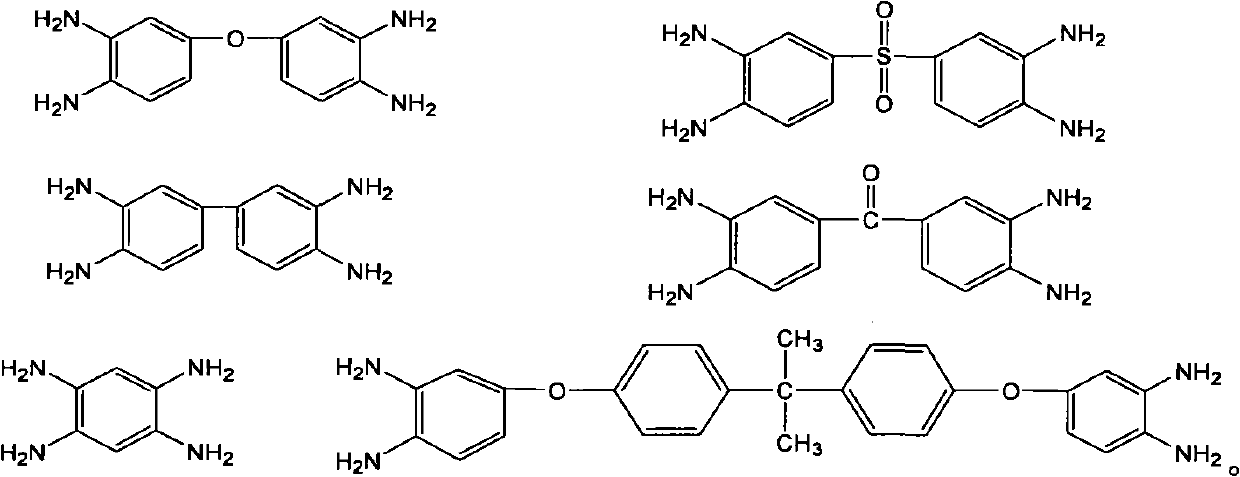

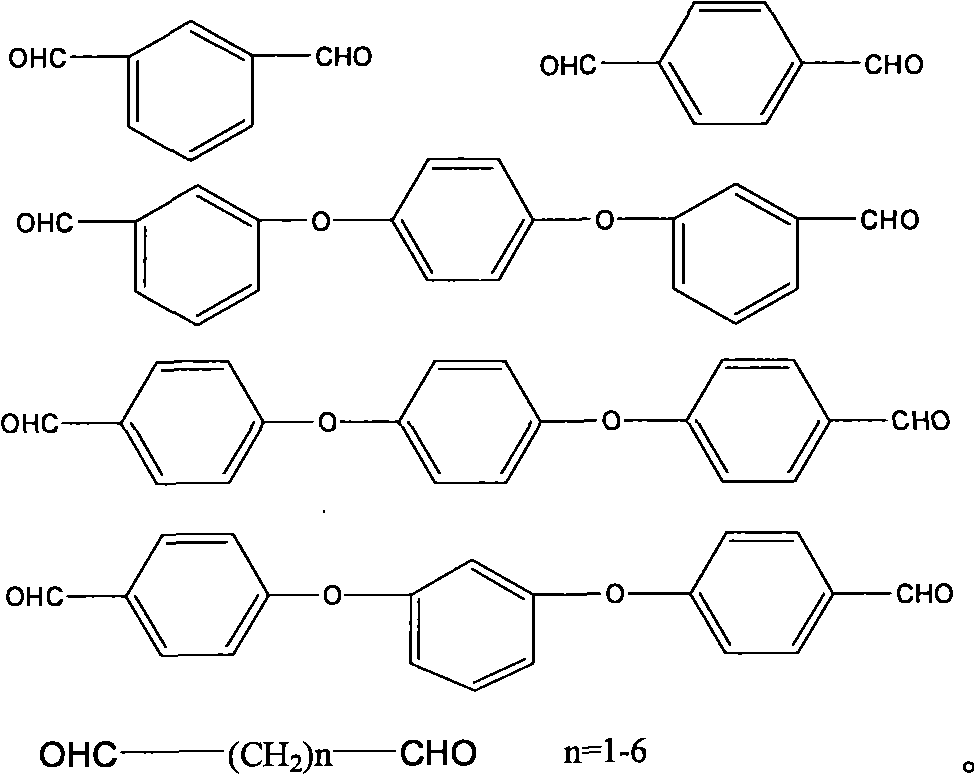

The invention discloses a method for preparing a polybenzimidazole / sulfonated polymer composite proton exchange membrane material, and belongs to the technical field of preparation of functional polymer materials. The method comprises the following steps of: transforming a sulfonated polymer into a sulfonate polymer by alkali treatment, dissolving the sulfonate polymer in an organic solvent, and adding a catalyst, and tetramine monomers and dialdehyde monomers in an equimolar ratio; and stirring the mixture to obtain membrane making liquid; making a membrane and transforming the membrane to obtain the polybenzimidazole / sulfonated polymer composite proton exchange membrane material, wherein the tetramine monomers are one or any combination of compounds which have the molecular structures shown in the specifications; and each component has the advantages of uniform dispersion and simple operation. The prepared polybenzimidazole / sulfonated polymer composite proton exchange membrane material has the advantages of high mechanical strength, high electric conductivity, great improvement on dimensional stability, methanol permeability and temperature tolerance, and suitability for the fields of direct methanol fuel cells (DMFCs), the proton exchange membranes of proton exchange membrane fuel cells (PEMFCs), ion exchange resin, membrane separation, sensors and the like.

Description

technical field The invention relates to a polybenzimidazole / sulfonated polymer composite proton exchange membrane material prepared by an in-situ polymerization method, and belongs to the technical field of preparation of functional polymer materials. technical background Polymer proton exchange membrane is the key material of proton exchange membrane fuel cell (PEMFC) and direct methanol fuel cell (DMFC). important role. At present, the proton exchange membrane materials commonly used in PEMFC and DMFC are perfluorosulfonic acid membranes. This type of material has high proton conductivity, chemical and mechanical stability, but its temperature resistance, alcohol resistance, and dimensional stability Poor performance and extremely expensive, these shortcomings become one of the obstacles hindering its large-scale application in PEMFC and DMFC, so looking for a new type of non-fluorine proton exchange membrane with low cost, good temperature resistance and good alcohol re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08G73/18C08L79/04C08L71/10C08L81/06C08L79/08C08L25/06C08L71/12H01M8/02H01M2/16H01M8/10B01D71/72B01D71/62C08J5/22H01M8/1072

CPCY02E60/12Y02E60/522Y02E60/523Y02E60/50

Inventor 谢晓峰尚玉明冯少广王要武

Owner TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com