Novel nano-solid strong base catalyst, preparation method thereof and application thereof

A base catalyst and solid technology, which is applied in the field of new nano-solid strong base catalyst and its preparation and application, can solve the problems of low DMC yield, high temperature and pressure, etc., and achieve the advantages of simple preparation, simple composition and small dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

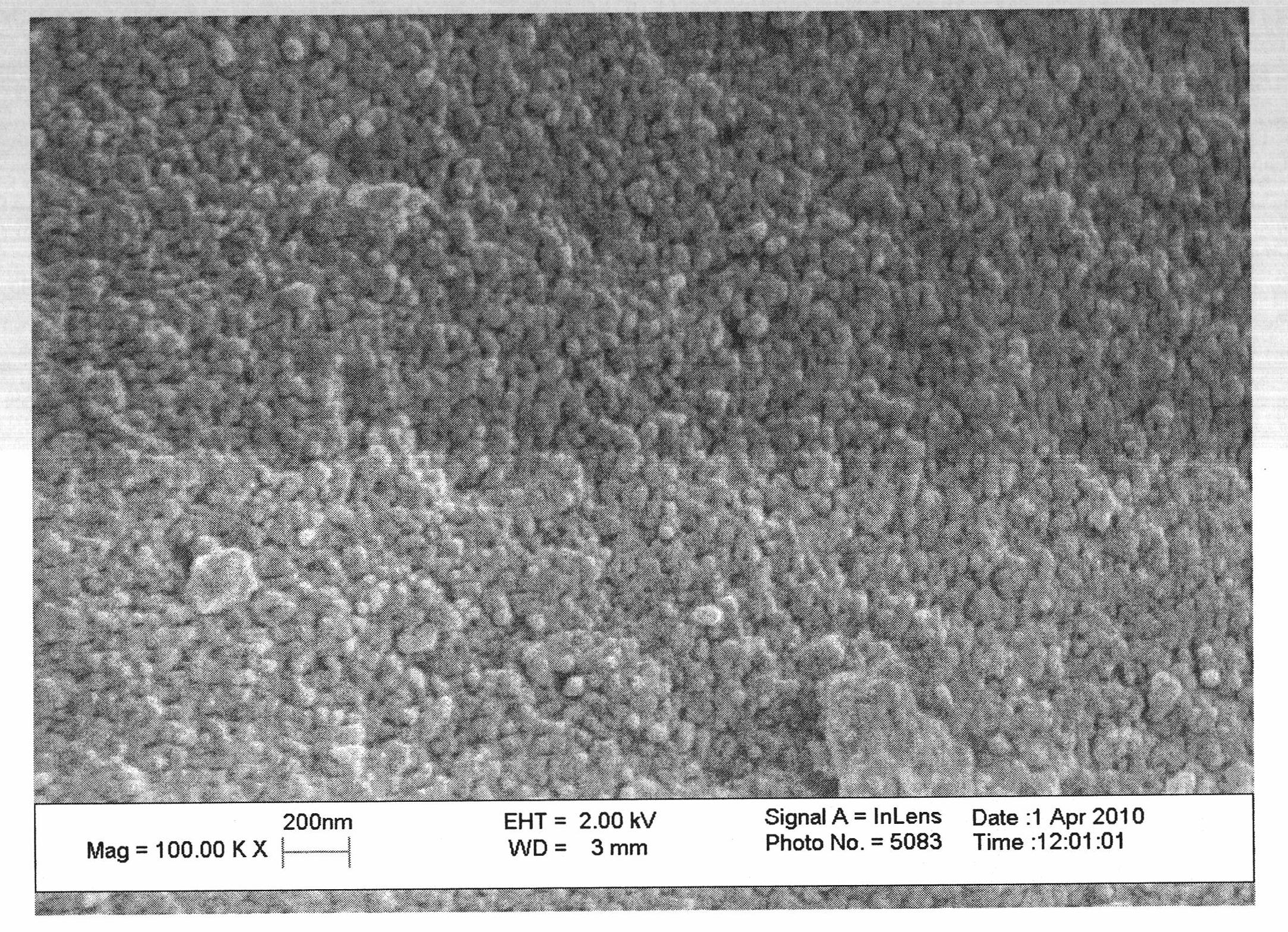

Image

Examples

Embodiment 1

[0030] Take 3.4g of SnCl 4 ·5H 2 O is dissolved in the NaOH solution of pH=12 to obtain a transparent solution, to which adding a mass fraction of 30% absolute ethanol solution (that is, the absolute ethanol solution accounts for 30% of the mass in the entire reaction system), and then the solution Put it into a crystallization kettle and crystallize at 150°C for 24 hours. The obtained precipitate was centrifuged, washed with water, dried, and heated to 450° C. for 4 hours under nitrogen at a rate of 5° C. / min and roasted for 4 hours to obtain the catalyst.

[0031] Add methanol, propylene carbonate and the above-mentioned catalyst into the reactor, the mol ratio of methanol and propylene carbonate is 9: 1, the catalyst consumption is 2.64wt%, and the reaction temperature is 60°C. After reacting for 6 hours, the product is centrifuged and taken The supernatant was analyzed by gas chromatography, and the conversion rate of PC was 53.4%.

[0032] The analysis of the product a...

Embodiment 2

[0035] Take 3.4g of SnCl 4 ·5H 2 O was dissolved in a pH=12 NaOH solution to obtain a transparent solution, 20% of the total mass of absolute ethanol was added thereto, and then the solution was placed in a crystallization kettle for crystallization at 150° C. for 8 hours. The obtained precipitate was centrifuged, washed with water, dried, and calcined at 5°C / min to 500°C for 4 hours under nitrogen to obtain the catalyst.

[0036] Ethanol, propylene carbonate and above-mentioned catalyst are added in the reactor, and the molar ratio of ethanol and propylene carbonate is 15: 1, and catalyst consumption is 2.64wt%, and reaction temperature is 120 ℃, after reacting for 6 hours, centrifugation of product, take The supernatant was analyzed by gas chromatography, and the conversion rate of PC was 33.6%.

Embodiment 3

[0038] Take 3.4g of SnCl 4 ·5H 2 O was dissolved in a pH=13 NaOH solution to obtain a transparent solution, 40% of the total mass of absolute ethanol was added thereto, and then the solution was placed in a crystallization tank and crystallized at 180° C. for 24 hours. The obtained precipitate was centrifuged, washed with water, dried, and heated to 550° C. for 6 hours under nitrogen at a rate of 5° C. / min and calcined for 6 hours to obtain the catalyst.

[0039] Add methanol, propylene carbonate and the above-mentioned catalyst into the reactor, the mol ratio of methanol and propylene carbonate is 15: 1, the catalyst consumption is 2.64wt%, and the reaction temperature is 80°C. After reacting for 6 hours, the product is centrifuged and taken The supernatant was analyzed by gas chromatography, and the conversion rate of PC was 79.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com