Preparation method of high-density high-safety long-life lithium cobaltate

A long-life, high-density technology, applied in chemical instruments and methods, cobalt compounds, inorganic chemistry, etc., can solve the problems of small particle diameter, long process time, and high energy of lithium cobaltate products, and achieve shortened crystal growth time, Effect of large particle diameter, improvement of safety performance and cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

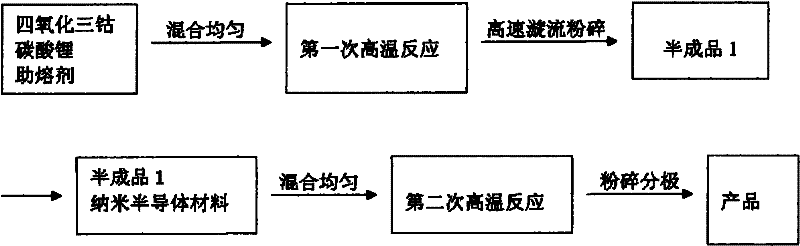

Method used

Image

Examples

Embodiment 1

[0019] Will Li 2 CO 3 and Co 3 o 4 Mix evenly with MgO according to the ratio of Li / Co=1.03, and the ratio of MgO to the whole material is 0.3%. The mixed material is sintered at 1000°C for 8 hours, and after cooling, it is crushed by high-speed swirl crushing. The crushed material is mixed with 1% nano-zinc oxide and sintered at 900°C for 5 hours. After cooling down, the material is crushed and classified. get the product. The medium particle size of its products is 12.3μm, the 1C discharge specific capacity is 155.7mAh / g, and the compacted density is 4.3g / cm 3 , 100 cycle capacity retention rate of 95.3%.

Embodiment 2

[0021] Will Li 2 CO 3 and Co 3 o 4 It is evenly mixed with sodium borate and lithium tetraborate according to the ratio of Li / Co=1.04, and the ratio of sodium borate and lithium tetraborate to the whole material is 1.0%. The mixed material is sintered at 950°C for 8 hours, and after cooling, it is crushed by high-speed swirl crushing. The crushed material is mixed with 0.5% nano-tin dioxide and sintered at 900°C for 8 hours. After cooling down, the material is crushed and classified , get the product. The particle size of the product is 13.7μm, the 1C discharge specific capacity is 157.2mAh / g, and the compacted density is 4.25g / cm 3 , 100 cycle capacity retention rate of 96.3%.

Embodiment 3

[0023] Will Li 2 CO 3 and Co 3 o 4 Mix evenly with calcium fluoride according to the ratio of Li / Co=1.05, and the proportion of calcium fluoride in the whole material is 0.2%. The mixed material is sintered at 1030°C for 10 hours, and after cooling, it is crushed by high-speed swirl crushing method. The crushed material is mixed with 0.3% nano-indium tin oxide and sintered at 980°C for 8 hours. After cooling down, the material is crushed and classified , get the product. The particle size of its products is 14.6μm, the 1C discharge specific capacity is 155.6mAh / g, and the compacted density is 4.25g / cm 3 , The 100-cycle capacity retention rate was 96.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com