Special carbon and graphite composite structure cathode carbon block of aluminum electrolytic cell

A cathode carbon block and aluminum electrolytic cell technology, which is applied in the field of graphite carbon composite structure cathode carbon blocks for aluminum electrolytic cells, can solve the problems of easy burning and damage of cathode steel rods, structural cost, high resistance value, low electrical conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

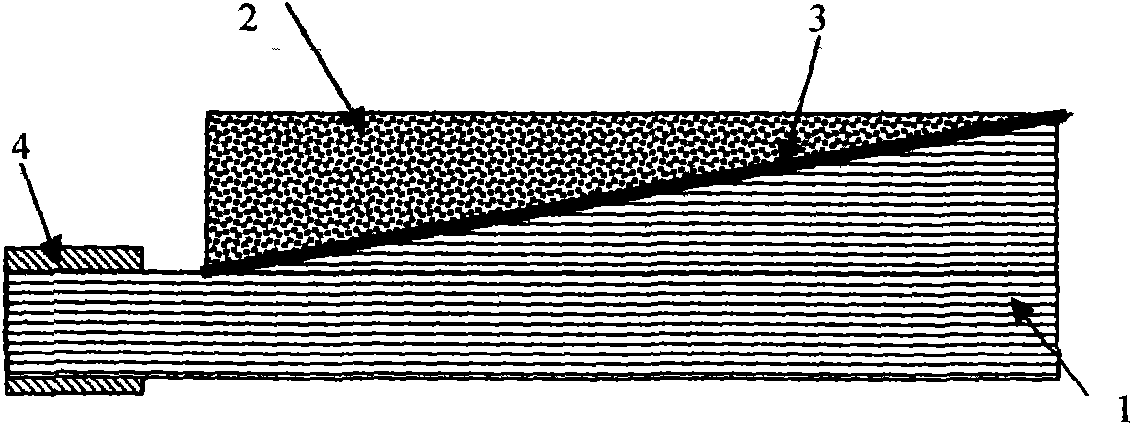

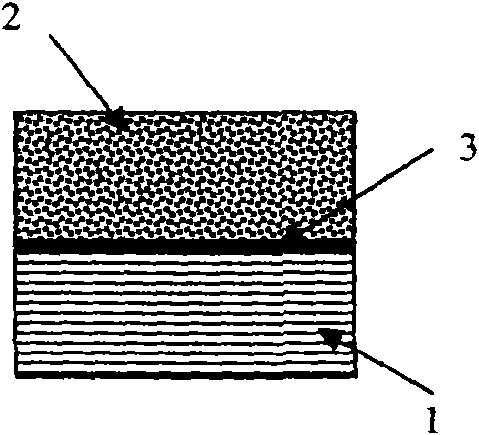

[0028] Embodiment 1: use graphite electrode (1) as the conductive material parts along the length direction of the cathode carbon block, build in the bottom of the cathode conductor, for conducting the horizontal current of the cathode carbon block elongation direction, the upper surface of the graphite electrode adopts etc. Slope design, from the DC input end to the output end slope downward; the upper part of the graphite electrode is determined by the resistivity ρ 2 Higher than graphite electrode resistivity ρ 1 The voltage-adjusting carbon layer (2) made of carbon, graphite or carbon-titanium boride material is constructed on the upper part of the graphite electrode (1) by high temperature resistant bonding conductive adhesive (3), and the upper part of the resistance carbon layer The surface is a horizontal structure. According to the inverse relationship between the material resistivity of Ohm's law and the length of the conductor, the structural size of the cathode car...

Embodiment 2

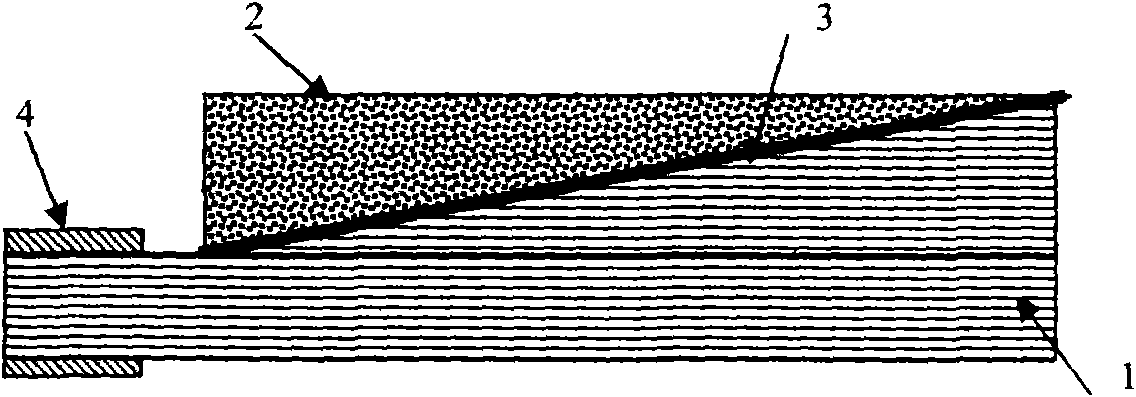

[0030] Embodiment 2: (as image 3 , Figure 4 Shown) On the basis of embodiment 1, the basic shape of the graphite electrode (1) of the cathode carbon block graphite electrode (1) of aluminum electrolytic cell special-purpose graphite carbon composite structure remains unchanged, and the voltage adjustment carbon layer (2) adopts graphite carbon-titanium boride mixed The material tamping structure is on the upper part of the graphite electrode (1), which is used to increase the voltage on the upper part of the cathode carbon block and adjust the impact resistance and sodium corrosion resistance of the carbon layer (2). The side and bottom are made of ordinary high-resistance carbon The tamping paste is used to tamp the layer to improve the electrical conductivity of the upper part of the cathode carbon block.

Embodiment 3

[0031] Embodiment 3: (as shown in Figure 5, Figure 6 As shown) the graphite electrode (1) of the cathode carbon block with graphite-carbon composite structure for aluminum electrolytic cells is structured as a conical frustum, and its cross-section changes with equal slopes along the length of the cathode carbon block, and its conductive cross-section gradually moves inward from the end increase. The outer diameter of the carbon layer (2) is adjusted by the voltage outside the graphite electrode (1), and the structure of the cathode carbon block is determined according to the proportional relationship between the material resistivity ρ, the conductive section S and the conductor length L according to Ohm's law Dimensions, manufacturing a graphite-carbon composite structure cathode carbon block dedicated to aluminum electrolytic cells with the equivalent value of the voltage drop V from the external surface of the cathode carbon block to the metal conductive connector at the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com