Ultrasonic standing wave type micro-fluidic chip and preparation method thereof

A microfluidic chip, ultrasonic standing wave technology, applied in the field of micro-total analysis system, can solve the problems of lack of chip operability and controllability research, acoustic wave chip stay, unfavorable marketization, etc. Controllable adjustment and simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

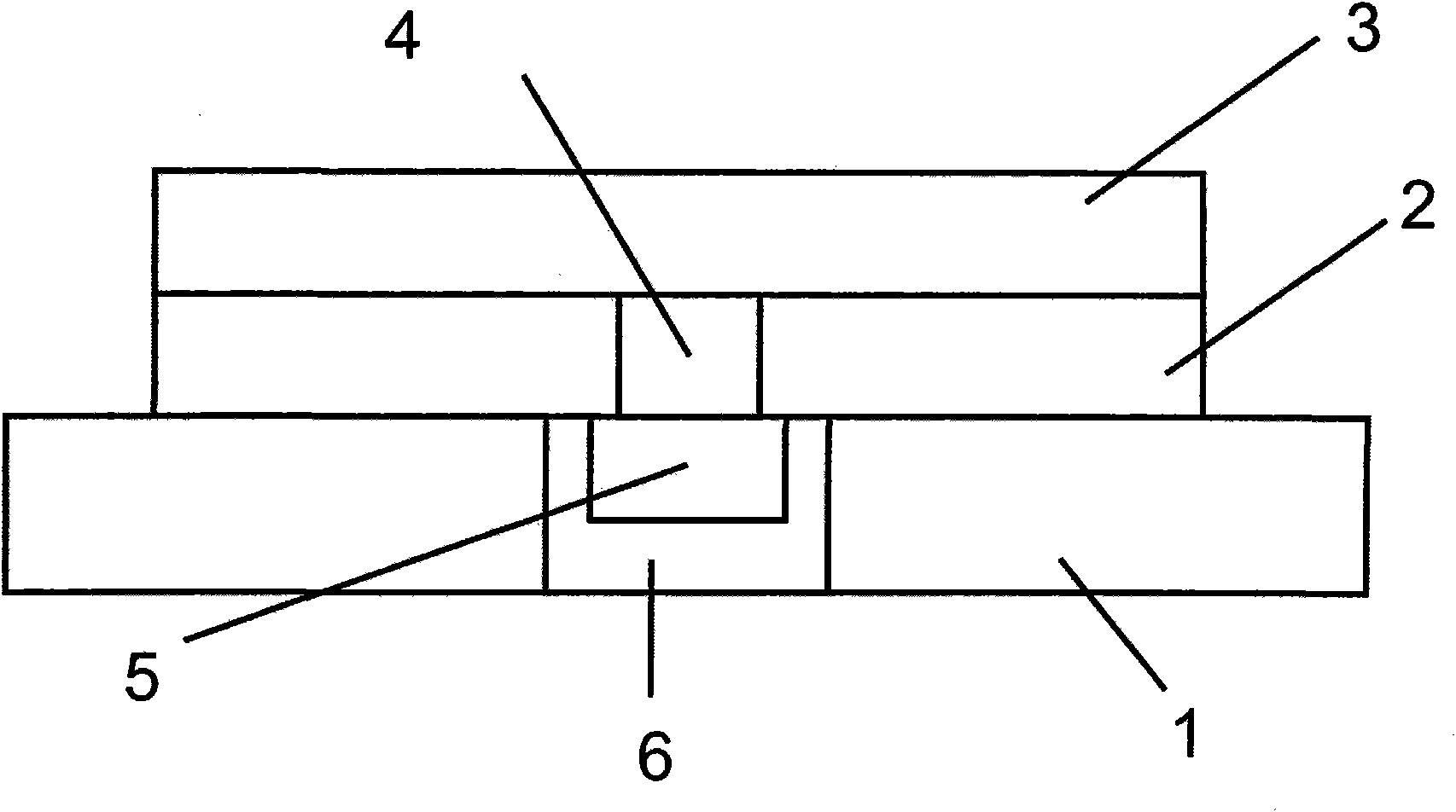

[0023] 1. Use the method of soft lithography to prepare the single crystal silicon positive mold template for the ultrasonic standing wave microfluidic chip. Only one standing wave reaction chamber (4) is designed in this template, forming a 1×1 standing wave reaction chamber array;

[0024] 2. Process a hole corresponding to the structure in the microfluidic chip on the PCB board (1) plated with a layer of copper on the surface, and install and fix the PZ26 piezoelectric ceramic sheet in the hole of the ultrasonic standing wave reaction chamber ( 5), as the sound source of the ultrasonic standing wave, wiring is carried out on the back of the PCB board (1) at the same time, and the input signal of the piezoelectric ceramic sheet (5) is connected to the output end of the control circuit;

[0025] 3. Pour the PDMS liquid prepolymer (2) on the positive mold template, and then put a glass slide (3) on the PDMS liquid prepolymer (2) on the male mold template. Demoulding, making a...

Embodiment 2

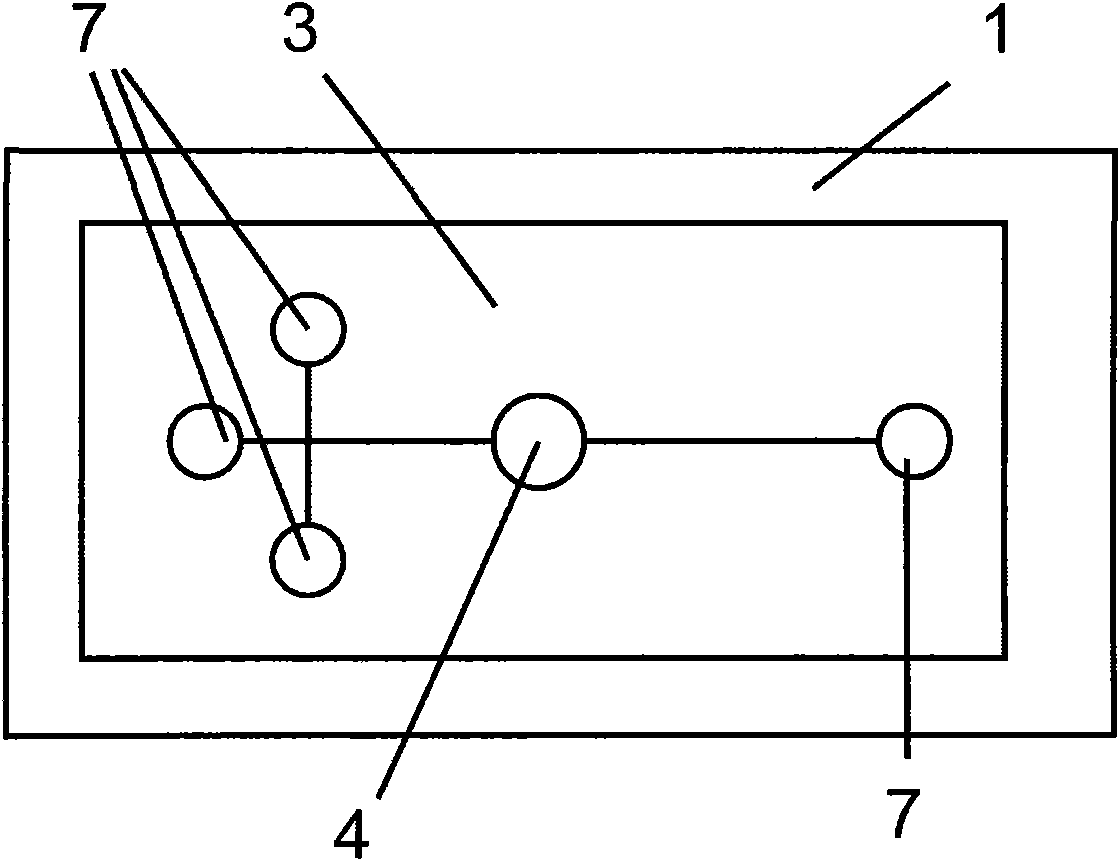

[0028] 1. The glass positive mold template for the ultrasonic standing wave microfluidic chip is prepared by soft lithography. Three standing wave reaction chambers (4) are designed in the template to form a 1×3 standing wave reaction chamber array;

[0029] 2. Process holes corresponding to the structure in the microfluidic chip on the PCB (1) coated with a layer of platinum on the surface, and install and fix three PZ26 pressure gauges in the holes corresponding to the ultrasonic standing wave reaction chamber. The electric ceramic sheet (5), as the sound source of the ultrasonic standing wave, is wired on the back of the PCB board (1) at the same time, and all the input signals of the piezoelectric ceramic sheet (5) are connected to the output ends of the three-way switch circuit, and Fix the circuit board welded with the three-way switch on both sides of the PCB board (1) as a bracket;

[0030] 3. Pour the PDMS liquid prepolymer (2) on the positive mold template, and then ...

Embodiment 3

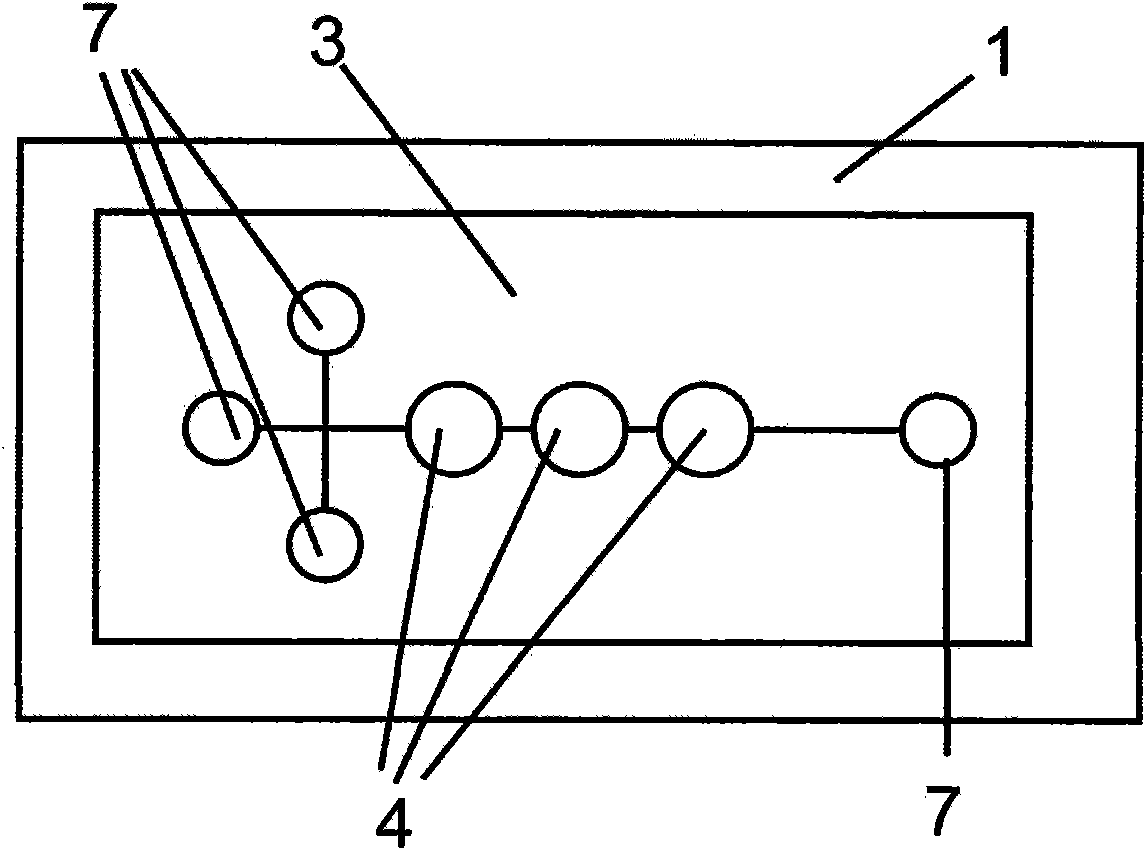

[0033] 1. The monocrystalline silicon positive mold template for the ultrasonic standing wave microfluidic chip is prepared by soft lithography, and 9 standing wave reaction chambers (4) are designed in the template to form a 3×3 array distribution;

[0034] 2. Process holes corresponding to the structure in the microfluidic chip on the PCB plated with a layer of gold on the surface, and install and fix nine PZ26 pressure sensors in the holes of the ultrasonic standing wave reaction chamber (4). The electric ceramic sheet (5), as the sound source of the ultrasonic standing wave, is wired on the back side of the PCB board (1) at the same time, and all the input signals of the piezoelectric ceramic sheet (5) are connected to the output ends of the nine-way switch circuit, and Fix the circuit board welded with the nine-way switch on both sides of the PCB board (1) as a bracket;

[0035] 3. Pour the PDMS liquid prepolymer (2) on the positive mold template, and then put a glass sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com