Method for producing protein feed by multi-strain solid state fermented vinegar residue

A solid-state fermentation, protein feed technology, applied in animal feed, animal feed, application and other directions, can solve problems such as insufficient comprehensiveness and rationality, and achieve the effects of improving palatability, improving the environment, and saving expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

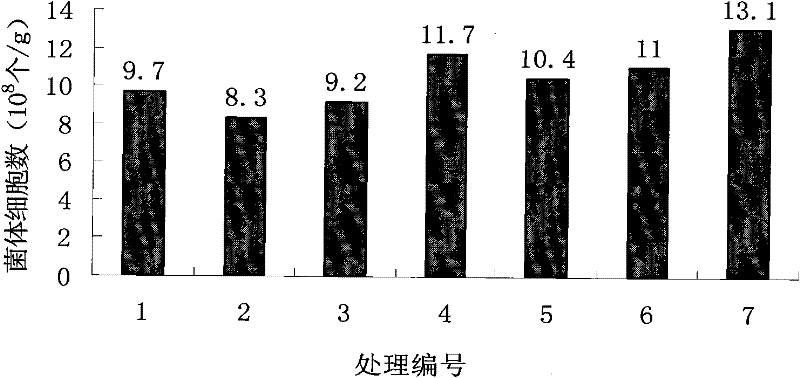

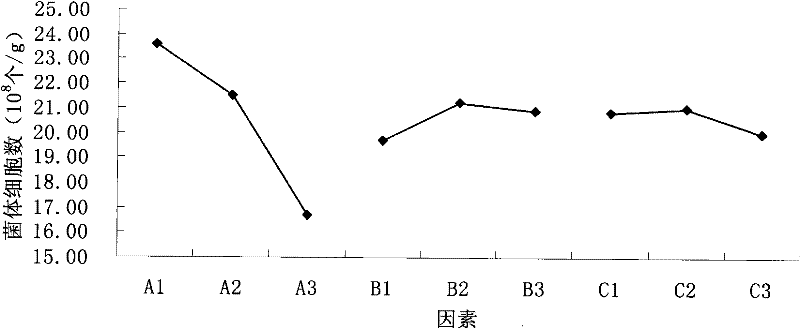

[0118] Embodiment 1, in order to adapt to the requirements of industrialization, it is necessary to carry out the enlarged fermentation test of large container. On the basis of the optimal fermentation raw material ratio and the optimal fermentation process conditions in the above experiment, an expanded fermentation test was carried out, 500g of mixing material was put into a porcelain plate, and it was placed in a constant temperature incubator at 28°C for 72 hours of fermentation. Its bacterial cell number, crude protein, true protein, enzyme activity and amino acid composition.

[0119] Strains: Pleurotus ostreatus + Geotrichum candidum + Saccharomyces cerevisiae + Candida utilis.

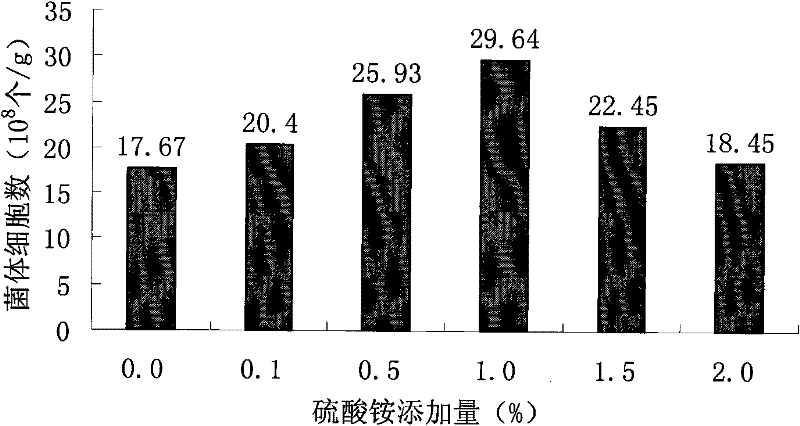

[0120] Fermentation medium: 250g of fresh vinegar grains, 125g of distiller's grains, 75g of bran, 50g of corn flour, then add 1% of ammonium sulfate, 0.8% of potassium dihydrogen phosphate, 0.8% of magnesium sulfate, the ratio of material to water is 1:0.6, and the inoculum size is 10% , the ...

Embodiment 2

[0143] Embodiment 2, a method for producing protein feed by solid-state fermentation of vinegar grains with multiple strains,

[0144] Strains: Pleurotus ostreatus + Geotrichum candidum + Saccharomyces cerevisiae + Candida utilis.

[0145] Fermentation medium: 300g fresh vinegar grains, 100g distiller's grains, 50g bran, 50g corn flour, then add 1.5% ammonium sulfate, 0.6% potassium dihydrogen phosphate, 1.0% magnesium sulfate, material-water ratio 1:0.5, inoculum size 15% , inoculation ratio Pleurotus ostreatus: Saccharomyces cerevisiae+Candida utilis+Geotrichum candidum=1: 3 (wherein Saccharomyces cerevisiae: Candida utilis: Geotrichum candidum=1: 1: 1), fermentation temperature 30 ℃, fermentation time is 120h.

[0146] Fermentation process flow: slant strains, liquid strains, and fermentation raw materials are mixed evenly, inoculated (15% inoculum), fermented at 30° C. for 72 hours, and dried at 40° C. to obtain a finished product.

Embodiment 3

[0147] Embodiment 3, a method for producing protein feed by solid-state fermentation of vinegar grains with multiple strains,

[0148] Strains: Pleurotus ostreatus + Geotrichum candidum + Saccharomyces cerevisiae + Candida utilis.

[0149] Fermentation medium: 280g of fresh vinegar grains, 120g of distiller's grains, 60g of bran, 40g of corn flour, then add 0.5% of ammonium sulfate, 1.0% of potassium dihydrogen phosphate, 0.4% of magnesium sulfate, the ratio of material to water is 1:0.7, and the inoculum size is 20% , inoculation ratio Pleurotus ostreatus: Saccharomyces cerevisiae+Candida utilis+Geotrichum candidum=1: 3 (wherein Saccharomyces cerevisiae: Candida utilis: Geotrichum candidum=1: 1: 1), fermentation temperature 30 ℃, fermentation time is 120h.

[0150] Fermentation technological process: slant strains, liquid strains, and fermentation raw materials are mixed evenly, inoculated (20% inoculum size), fermented at 30° C. for 72 hours, and dried at 40° C. to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com