Split-type differential drive device and omnibearing movable automatic guided vehicle thereof

A differential drive and moving device technology, applied in the direction of non-deflectable wheel steering, vehicle parts, transportation and packaging, etc., can solve the problems of large movement space, high manufacturing cost, and difficulty in accurately controlling the movement state of the driving wheel, and achieve easy Good maintenance, low manufacturing cost, precise control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The composition structure of the separable differential drive device and the operation process of the path adaptive tracking control method of the present invention will be described in detail below according to the embodiments shown in the accompanying drawings.

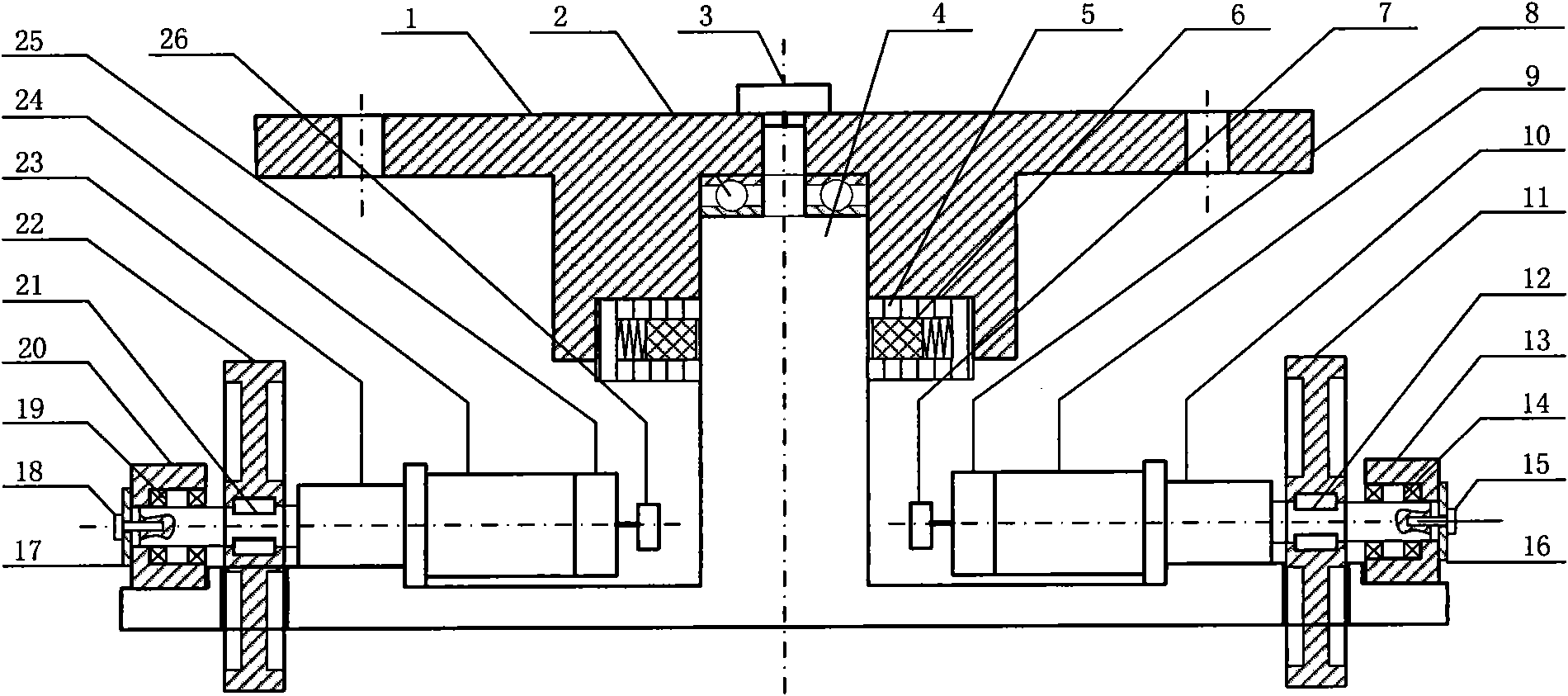

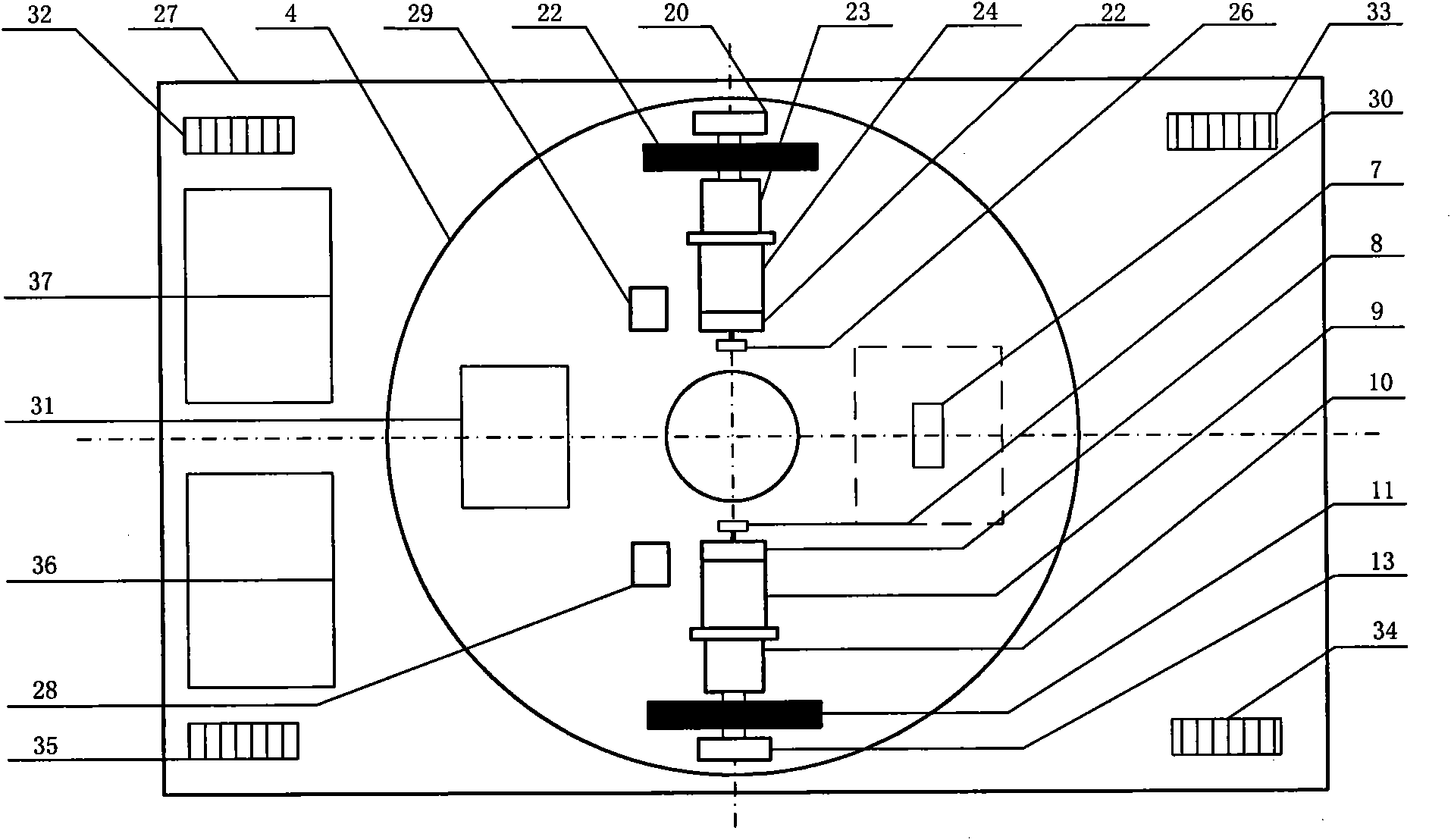

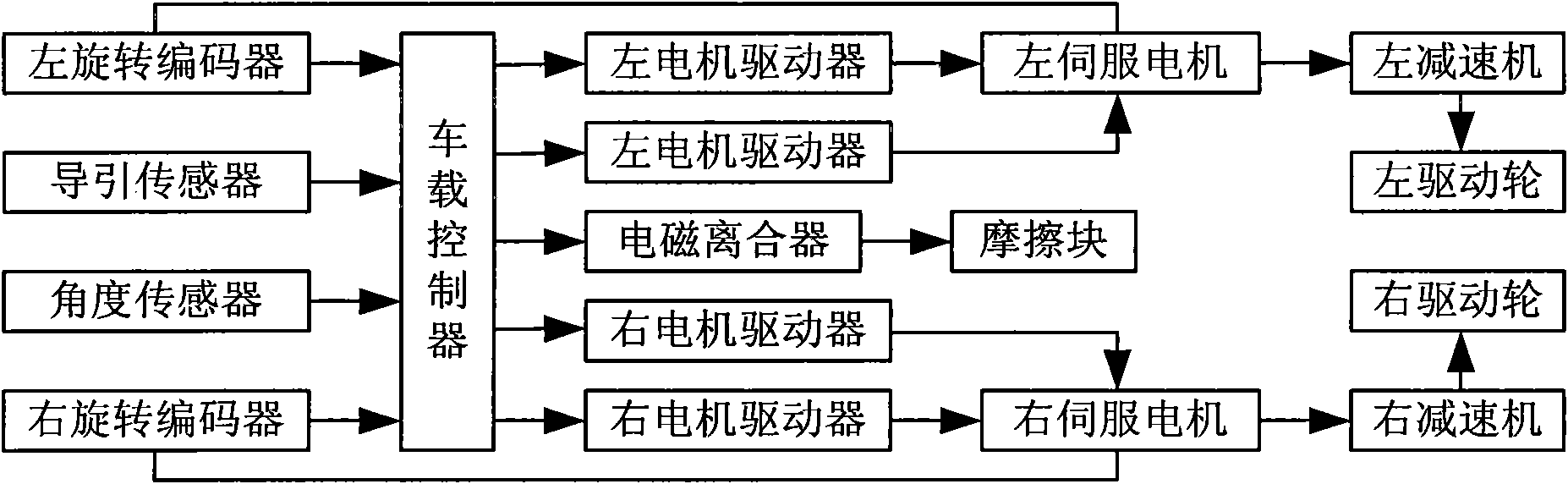

[0058] refer to figure 1 , the separable differential drive device of the present invention is made of detachable upper turntable 1 and lower turntable 4, wherein the upper turntable 1 has a central hole, and the upper end of the lower turntable 4 has a central shaft; the center hole of the upper turntable 1 It is coaxially assembled with the central shaft of the lower turntable 4 through a thrust bearing 2; while bearing the axial load, it is ensured that the central shaft of the lower turntable 4 can rotate freely in the center hole of the upper turntable 1. A cylindrical electromagnetic clutch 5 is also installed between the central hole of the upper rotating disk 1 and the central axis of the lower rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com