A preparation device and preparation method of composite particles for polishing

A composite particle and preparation device technology, which is applied in the direction of grinding/polishing equipment, surface polishing machine tools, grinding devices, etc., can solve the problems of lack of universality, complex abrasive movement, and low polishing efficiency, so as to improve the polishing efficiency. Improve the efficiency and utilization of abrasives, enhance the bonding strength, and solve the effect of low polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

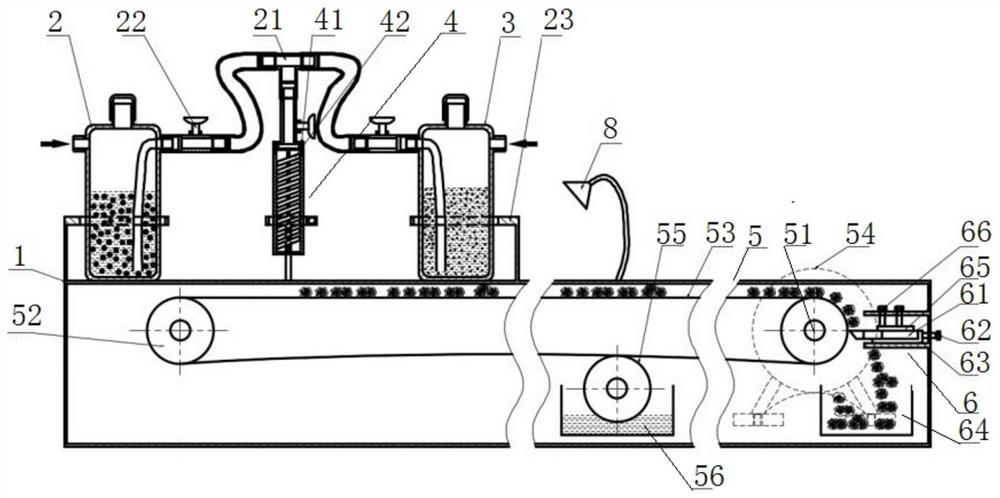

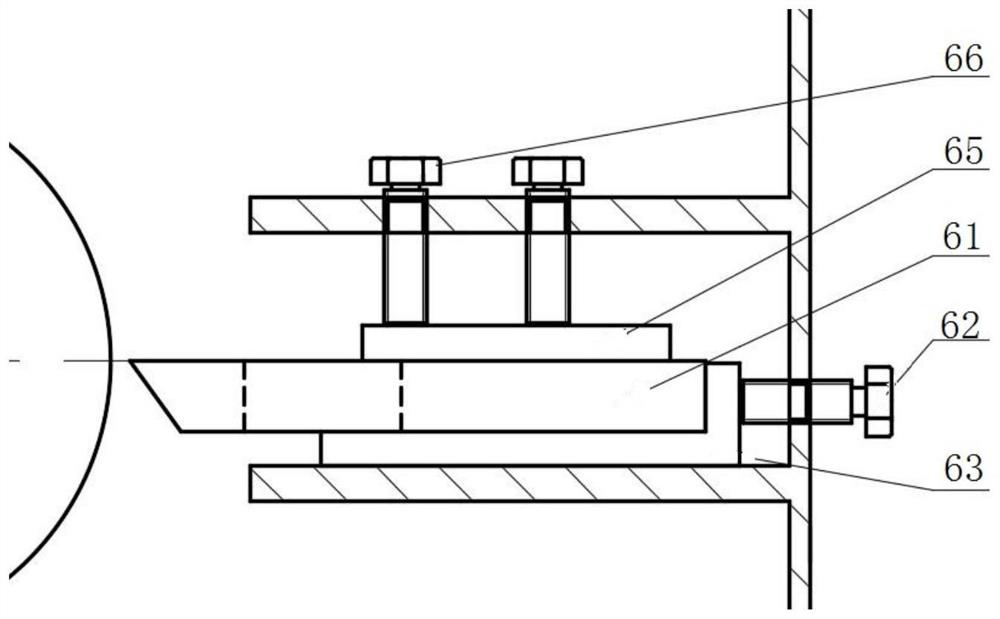

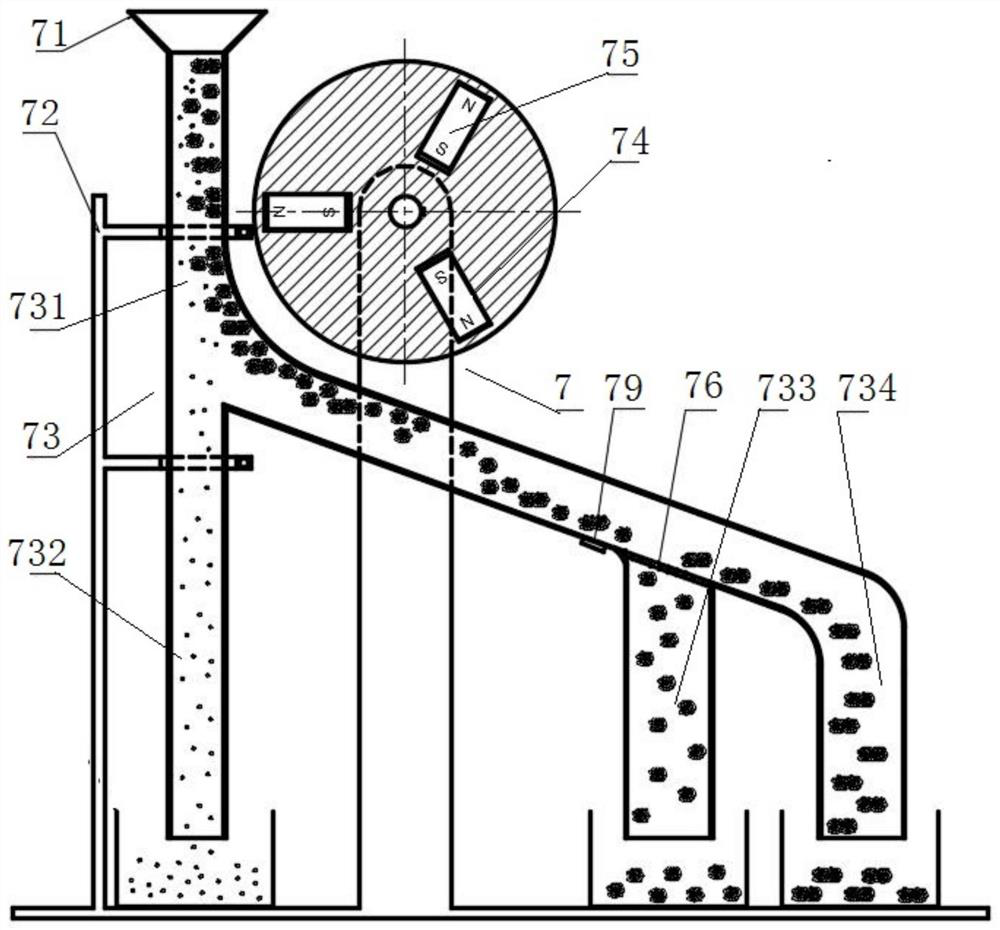

[0033] like Figure 1 to Figure 4 Shown is the embodiment of the preparation device of the composite particles for polishing of the present invention, including a base 1, a first spraying mechanism 2, a second spraying mechanism 3, a mixing and dispersing mechanism 4, a conveying mechanism 5, and a composite particle group for scraping The scraping mechanism 6, the ball milling mechanism for processing composite particle agglomerates to composite particle powder, and the screening mechanism 7 for screening composite particles within a set size range, the first spraying mechanism 2, the second spraying mechanism 3, the mixing and dispersing mechanism 4, and the conveying mechanism 5 is fixed on the base 1; the first spraying mechanism 2 is filled with magnetic particles coated with a binder on the surface, the second spraying mechanism 3 is filled with abrasives coated with a binder on the surface, and the mixing and dispersing mechanism 4 An input end connected with the first ...

Embodiment 2

[0041] This example is an example of the method for preparing composite particles for polishing of the present invention. The magnetic particles in this example are carbonyl iron powder with a particle size of micron; the abrasive is diamond micropowder with a particle size of submicron. This embodiment includes the following steps:

[0042] S10. Measure 400ml of carbonyl iron powder with a particle size of 3 microns and 400ml of improved UV-curable adhesive (Ailete3342) in equal volumes to form the first mixed solution and add it to the first spraying mechanism 2. Measure 400ml with a particle size of 0.5 micron diamond powder and 400ml improved UV curing adhesive (Ailete 3342) are uniformly mixed in equal volumes to form a second mixed solution that is added to the second spraying mechanism 3, and the first spraying mechanism 2 and the second spraying mechanism 3 are equipped with Fix the clip structure on the high-pressure bottle bracket, adjust and turn on the air pump, ul...

Embodiment 3

[0049] This embodiment is an embodiment of the preparation method of the composite particles for polishing of the present invention. This embodiment is similar to Embodiment 2, the difference is that the particle size of the magnetic particles in this embodiment is submicron, and the abrasive material The particle size is nanoscale. This embodiment includes the following steps:

[0050] S10. Measure 500ml of carbonyl iron powder with a particle size of 1 micron and 500ml of improved UV-curable adhesive (Ailete3525) in equal volumes to form the first mixed solution and add it to the first spraying mechanism 2, and measure 400ml with a particle size of The 50nm diamond micropowder and 400ml improved UV-curable adhesive (Ailete 3525) are evenly mixed to form the second mixed liquid, which is added to the second spraying mechanism 3, and the first spraying mechanism 2 and the second spraying mechanism 3 adopt a clamping structure Fix it on the high-pressure bottle bracket, adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com