Lactic acid-producing engineering bacteria, constructing method thereof and application thereof

A construction method and technology of engineering bacteria, applied in the fields of genetic engineering and fermentation engineering, can solve the problems of high nutritional demand of lactic acid bacteria and restricting the development of L-lactic acid fermentation industry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

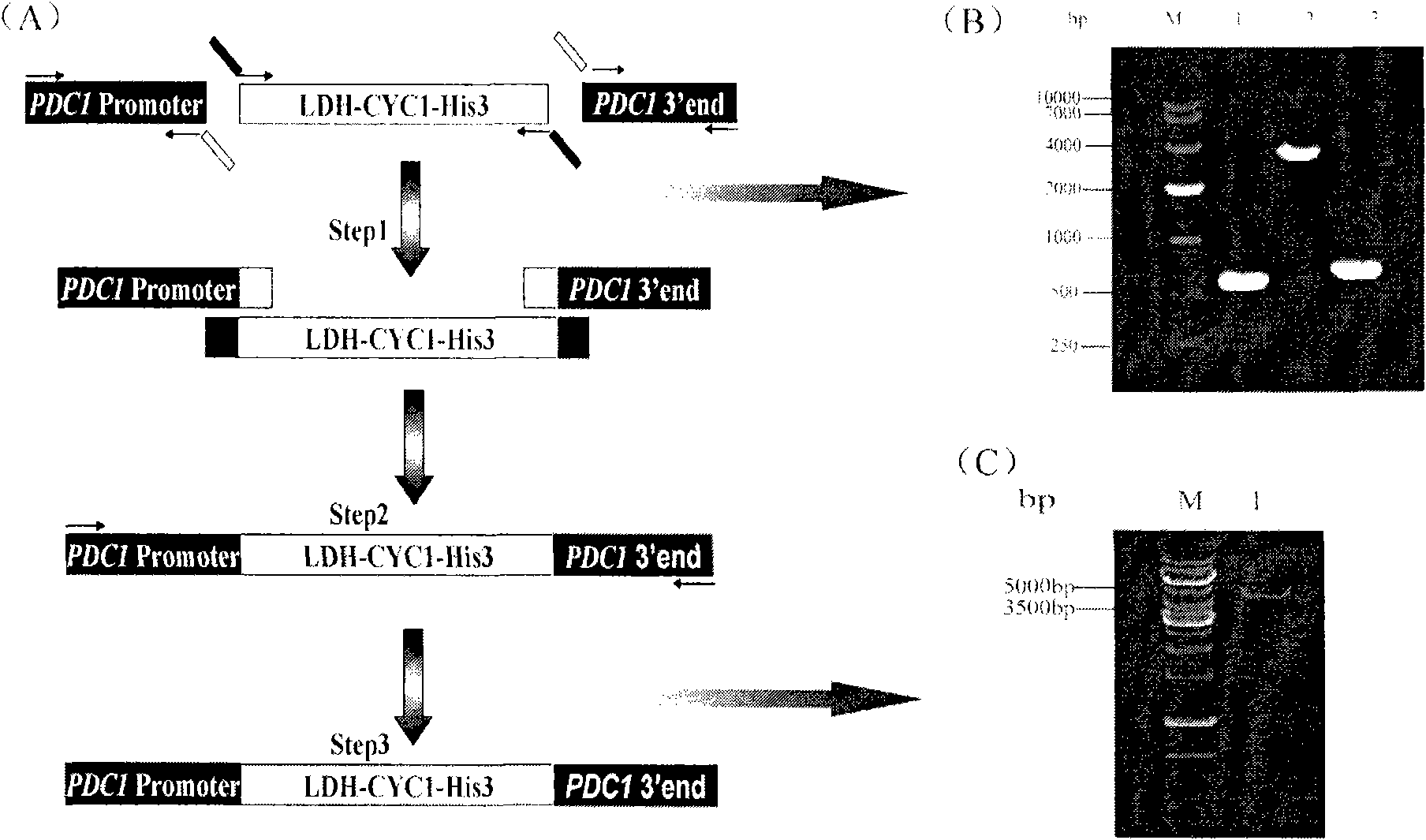

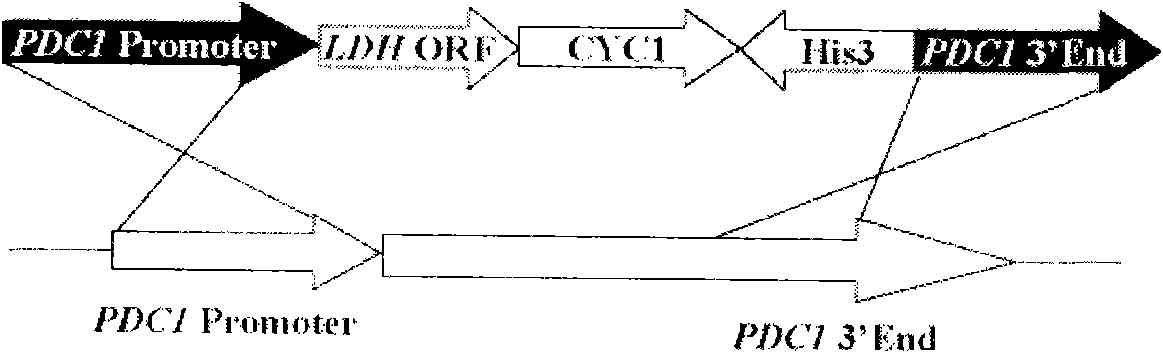

[0030] Embodiment 1 produces the construction of lactic acid engineering bacteria

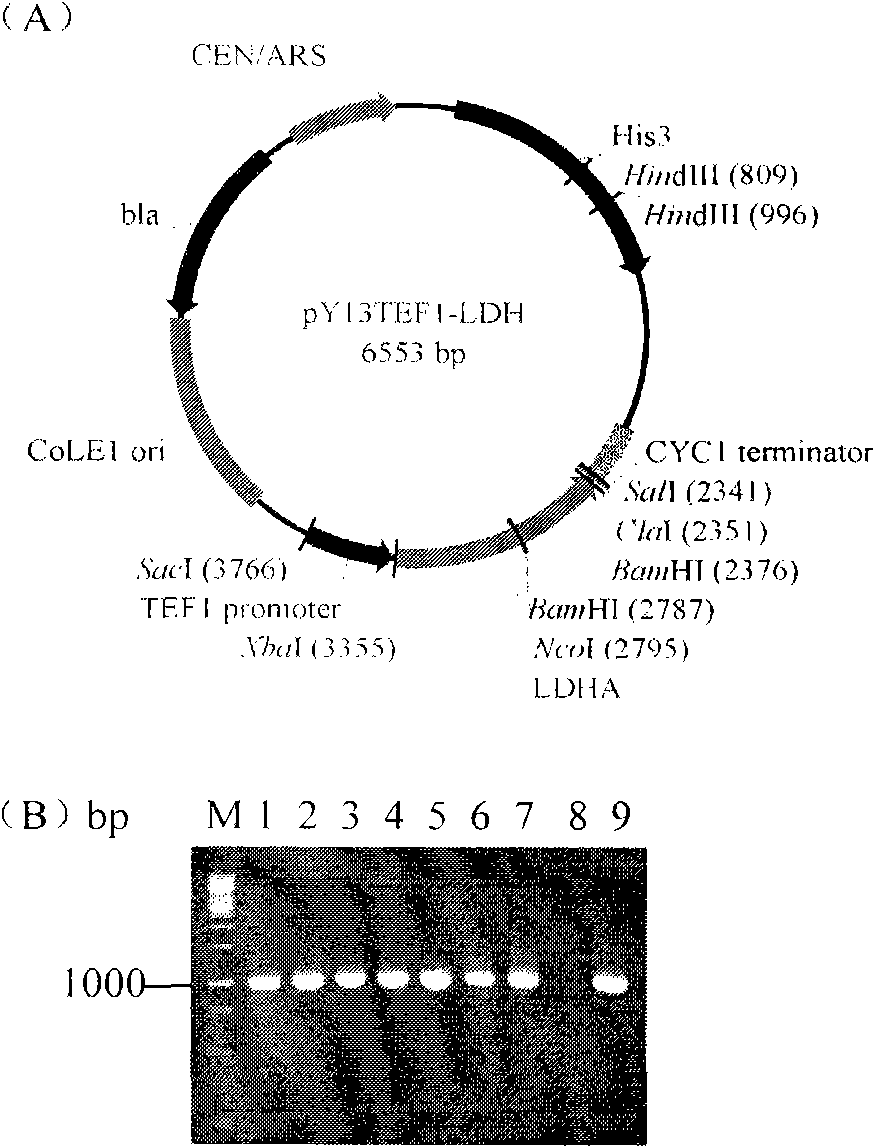

[0031] 1. Cloning of Bovine LDH gene

[0032] Using the plasmid pLAZ10 (Bianchi, 2010. Efficient Homolactic Fermentation by Kluyveromyces lactis Strains Defective in Pyruvate Utilization and Transformed with the Heterologous LDH Gene. ApplEnviron Microbiol, 67(12): 5621-5625.) as a template, the LDH fragment was amplified by PCR. Using LDH-F and LDH-R with XbaI and ClaI restriction sites as primers, the LDH fragment and plasmid pY13TEF1 (purchased from Delbao Biotechnology Co., Ltd.) were double-digested, purified, and Ligation construction plasmid pY13TEF1-LDH ( figure 1 A). After the ligation product was transformed into JM109 competent cells, the LB plate with ampicillin resistance was spread, cultured overnight at 37°C, and the transformant was picked for verification, as figure 1 b. The positive transformant was inoculated into liquid LB medium, the plasmid was extracted, digested, ver...

Embodiment 2

[0046] Embodiment 2 fermentation produces lactic acid

[0047] Connect a loop of the lactic acid-producing engineered bacteria from the fresh slant to the seed medium (80mL SC / 250mL Erlenmeyer flask), and culture it to the mid-logarithmic phase (24h) at 30°C and 200r / min in a shaker flask, then use 8% inoculum (v / v) into a 1.3L fermentor equipped with 700mL of YNB fermentation medium. During the fermentation process, the pH was maintained at 5.5 with 4mol / L NaOH, the ventilation rate was 1.5L / min, and the dissolved oxygen was controlled at 50%. After 100 hours of fermentation, the lactic acid production reached 15g / L.

[0048] The composition of the seed medium is (g / L): glucose 20, YNB (withoutNH 4 SO 4 ) 1.7, ammonium sulfate 4, the required amount of amino acid.

[0049] The composition of YNB fermentation medium is (g / L): CaCO 3 4.5, YNB (without NH 4 SO 4 ) 1.7, urea 1, ethanol 5, glucose 70, the required amount of amino acids.

Embodiment 3

[0050] The detection of embodiment 3L-lactic acid, ethanol and glucose

[0051] Determination of L-lactic acid and ethanol concentration: Agilent A1200 high performance liquid chromatography (HPLC) instrument was used for determination.

[0052] Chromatographic conditions

[0053] Chromatographic column: Aminex HPX-87H (Bio-Rad)

[0054] Mobile phase: 0.005mol / L -1 h 2 SO 4

[0055] Flow rate: 0.6mL / min -1

[0056] Column temperature: 35°C

[0057] Injection volume: 5μL

[0058] Detector: Differential Refractive Index

[0059] Sample preparation: Centrifuge 5 mL of fermentation broth at 10,000 rpm for 10 min, and transfer the supernatant into a test tube for use in the measurement of L-lactic acid, ethanol, and residual glucose. When measuring L-lactic acid, take 1mL of the supernatant and transfer it into a 10mL volumetric flask, dilute to the mark with deionized water, filter through a 0.45μm filter membrane, and use the filtrate for liquid chromatography analysis....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com