Fermentation method of co-production of astaxanthin and Fructooligosaccharide

A technology of fructo-oligosaccharide and fermentation method, which is applied in the field of biomedicine, can solve the problems of inability to produce astaxanthin and fructo-oligosaccharide at the same time, low medium concentration, and low astaxanthin content, so as to shorten the fermentation cycle and improve the applicability Wider and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) The medium composition is: glucose 1%, yeast extract 1%, ammonium sulfate 1.5%, disodium hydrogen phosphate 0.1%, potassium dihydrogen phosphate 0.1%, magnesium sulfate 0.1%, calcium chloride 0.04%, water 96.16% .

[0020] (2) Calculation and weighing of cultured ingredients: Take the fermentation in a 10-ton tank as an example, and the initial fermentation volume is 4m 3 Then the initial culture of the preparation fermentation needs: glucose = 1% × 1000L / m 3 ×4m 3 ×1000g / L=40kg, yeast extract=1%×1000L / m 3 ×4m 3 ×1000g / L=40kg, (NH 4 ) 2 SO 4 =1.5%×1000L / m 3 ×4m 3 ×1000g / L=60kg, Na 2 HPO 4 =0.1%×1000L / m 3 ×4m 3 ×1000g / L=4kg, KH 2 PO 4 =0.1%×1000L / m 3 ×4m 3 ×1000g / L=4kg, MgSO 4 =0.1%×1000L / m 3 ×4m 3 ×1000g / L=4kg, CaCl 2 =0.04%×1000L / m 3 ×4m 3 ×1000g / L=1.6kg, water=96.16%×1000L / m 3 ×4m 3 ×1000g / L=3966.4kg.

[0021] (3) Preparation and sterilization of the initial medium: weigh the above ingredients and mix them evenly, add water 3.7m 3 Mix eve...

Embodiment 2

[0026] (1) The medium components are: glucose 3%, yeast extract 2.5%, ammonium sulfate 2.4%, disodium hydrogen phosphate 0.4%, potassium dihydrogen phosphate 0.4%, magnesium sulfate 0.2%, calcium chloride 0.08%, water 91.02% .

[0027] (2) The weighing, preparation, sterilization, inoculation and fermentation process control of the culture medium are the same as in Example 1.

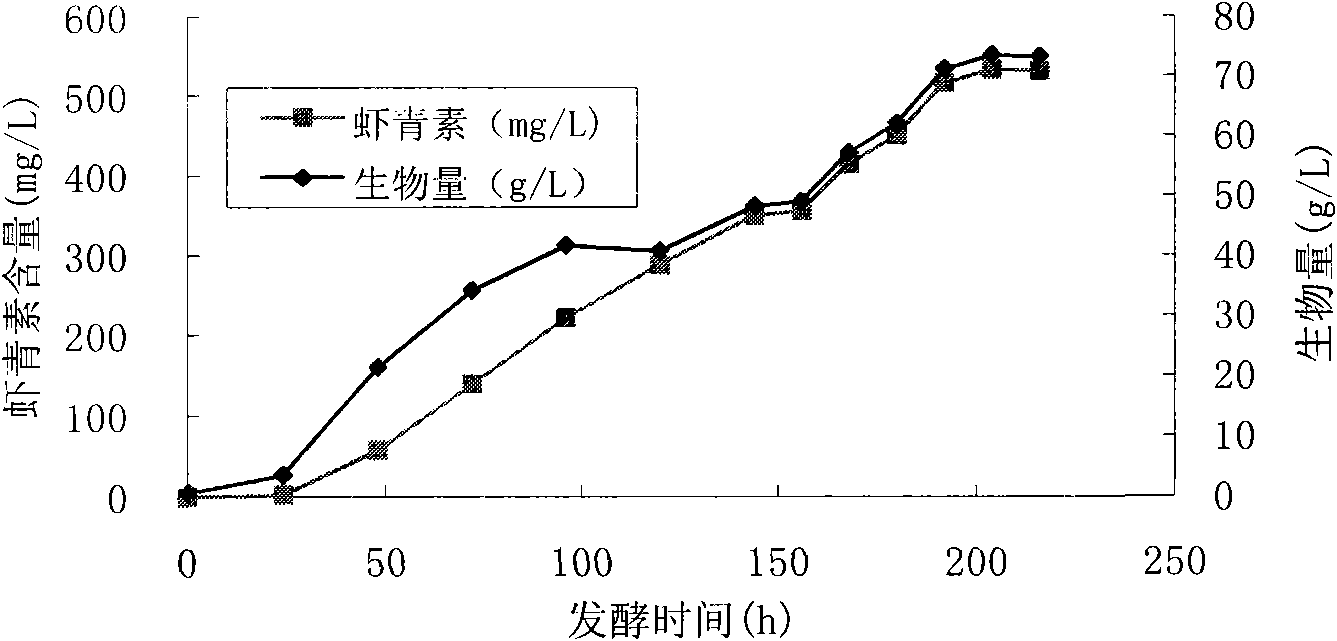

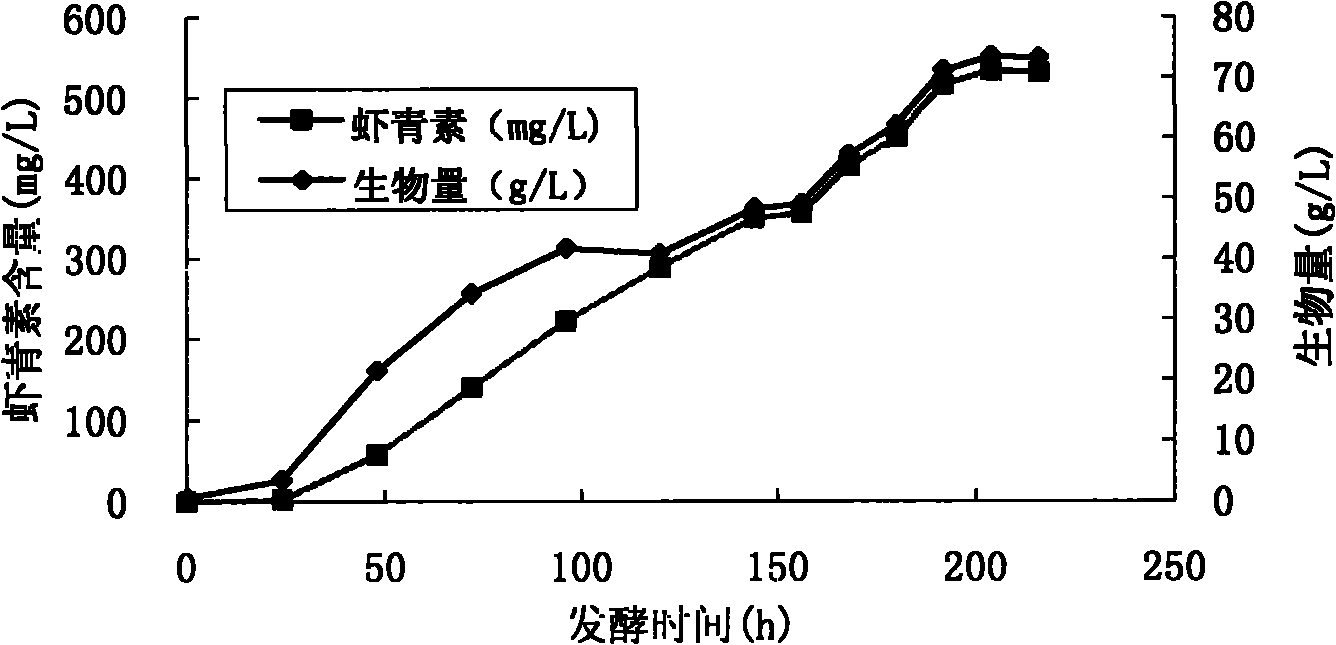

[0028] (3) Feeding: the operation of feeding is the same as in Example 1. When the feeding ends, the fermentation broth consumes 240g / L of sugar in total, the concentration of bacteria is 65g / L, and astaxanthin is 630mg / L.

Embodiment 3

[0030] (1) The medium composition is: glucose 2%, yeast extract 1.75%, ammonium sulfate 1.95%, disodium hydrogen phosphate 0.25%, potassium dihydrogen phosphate 0.25%, magnesium sulfate 0.15%, calcium chloride 0.06%, water 93.59% .

[0031] (2) The weighing, preparation, sterilization, inoculation and fermentation process control of the culture medium are the same as in Example 1.

[0032] (3) Feeding: The operation of feeding is the same as that of Example 1. When the feeding ends, the fermentation broth consumes a total of 240 g / L of sugar and the amount of bacteria is 75 g / L, and astaxanthin is 690 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com