Green environment-friendly fabric after-finishing neutralizer, preparation method and application thereof

A green and environmental-friendly finishing technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of incomplete neutralization of pH value in dyeing bath, rebound of pH value, hard hand feeling, etc., to save dipping time, penetrate fibers well, Neutralizes fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

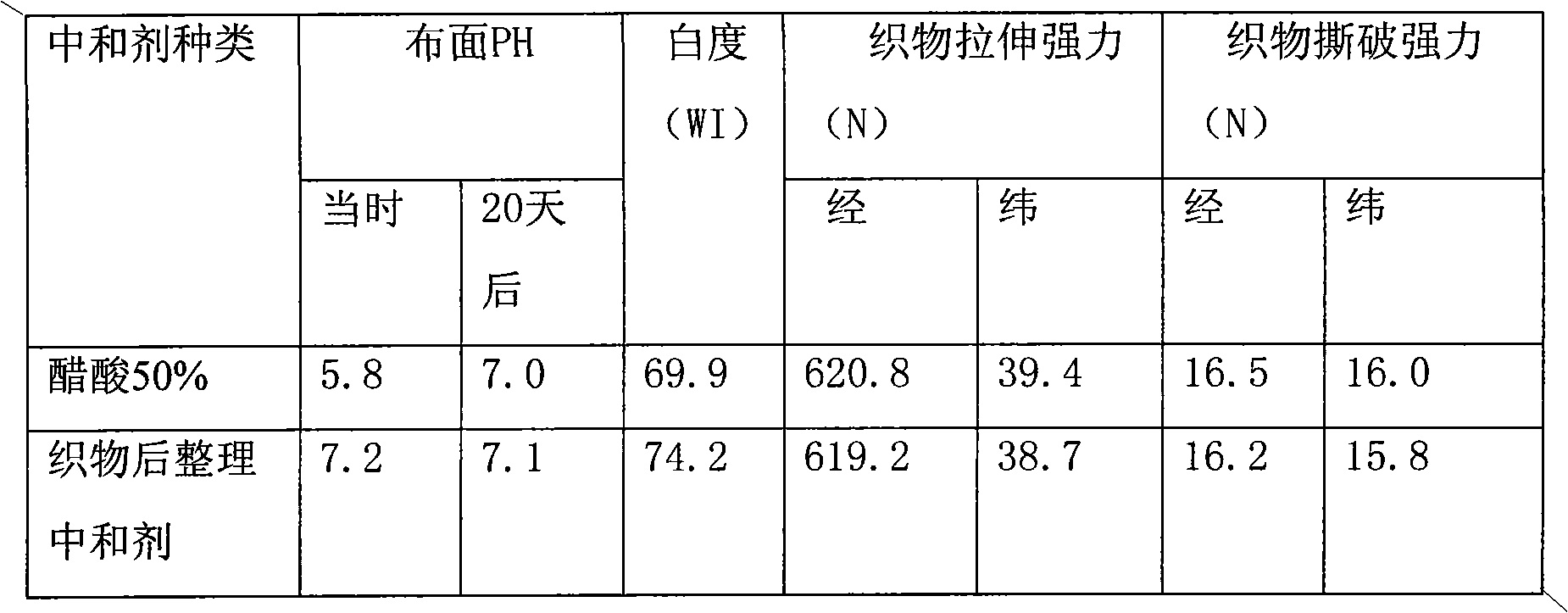

Examples

Embodiment 1

[0009] Embodiment 1: Inject 20 kilograms of concentrated sulfuric acid in the ceramic reactor with jacket circulating cooling water device, then slowly add 65 kilograms of urea, because the whole mixing process is exothermic process, must open circulating cooling water device cooling, control The temperature of the mixture does not exceed 60°C. After the urea is added, slowly add 15 kg of soft water, that is, deionized water after removing calcium and magnesium ions in tap water, and control the temperature of the mixture not to exceed 50°C. After all the materials are added , stop cooling, and continue to stir for 9 hours to make it. The green environmental protection fabric finishing neutralizer is used for fabrics after scouring, bleaching, dyeing, mercerizing, alkali reduction, stripping and other processes in the printing and dyeing industry. Removal of sodium hydroxide from cellulose fibers of textiles.

Embodiment 2

[0010] Embodiment 2: Inject 7 kilograms of concentrated sulfuric acid in the glass reactor with jacket circulating cooling water device, then slowly add 63 kilograms of urea, because the whole mixing process is exothermic process, must open circulating cooling water device cooling, control The temperature of the mixture does not exceed 70°C. After the urea is added, slowly add 30 kg of soft water, that is, deionized water after removing calcium and magnesium ions in tap water, and control the temperature of the mixture not to exceed 60°C. After all the materials are added , stop cooling, and continue to stir for 6 hours to make it. The green environmental protection fabric finishing neutralizer is used for fabrics after scouring, bleaching, dyeing, mercerizing, alkali reduction, stripping and other processes in the printing and dyeing industry. To the removal of the sodium hydroxide on the fabric cellulose fiber, all the other are with embodiment 1.

Embodiment 3

[0011] Embodiment 3: inject 81 kilograms of concentrated sulfuric acid in the ceramic reactor with jacket circulating cooling water device, then slowly add 16 kilograms of urea in the reactor, because the whole mixing process is an exothermic process, the circulating cooling water must be opened Cool the device and control the temperature of the mixture to not exceed 62°C. After the urea is added, slowly add 3 kg of soft water to the reactor to control the temperature of the mixture to not exceed 52°C. After all the materials are added, stop cooling and continue stirring for 4 hours Make conforming product, all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com