Smoke processing method for alumina roasting furnace

A technology of flue gas treatment and treatment method, applied in waste heat treatment, furnace, furnace components, etc., can solve problems such as adverse environmental impact, and achieve the effects of high heat utilization rate, reduced environmental impact, and large heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

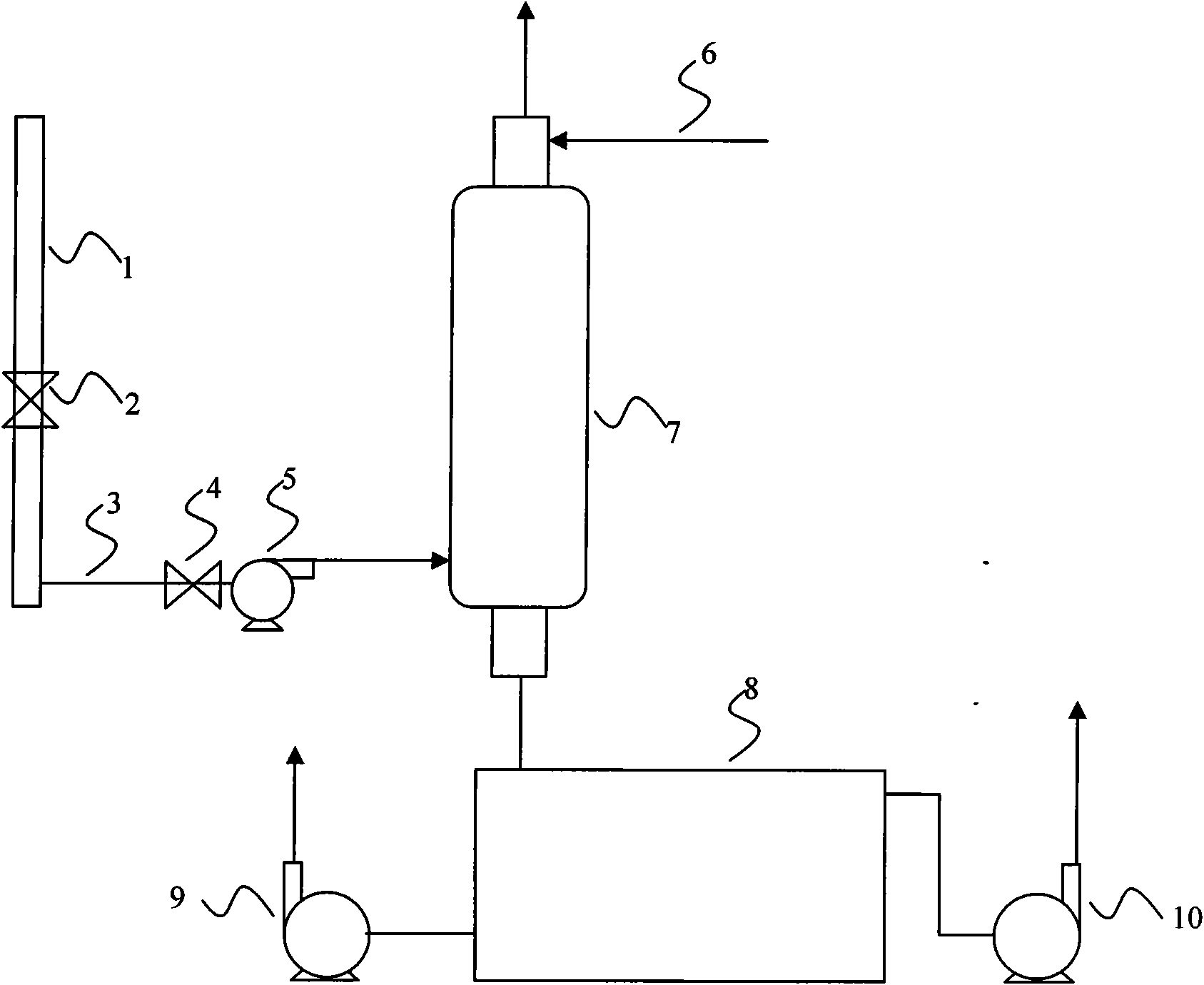

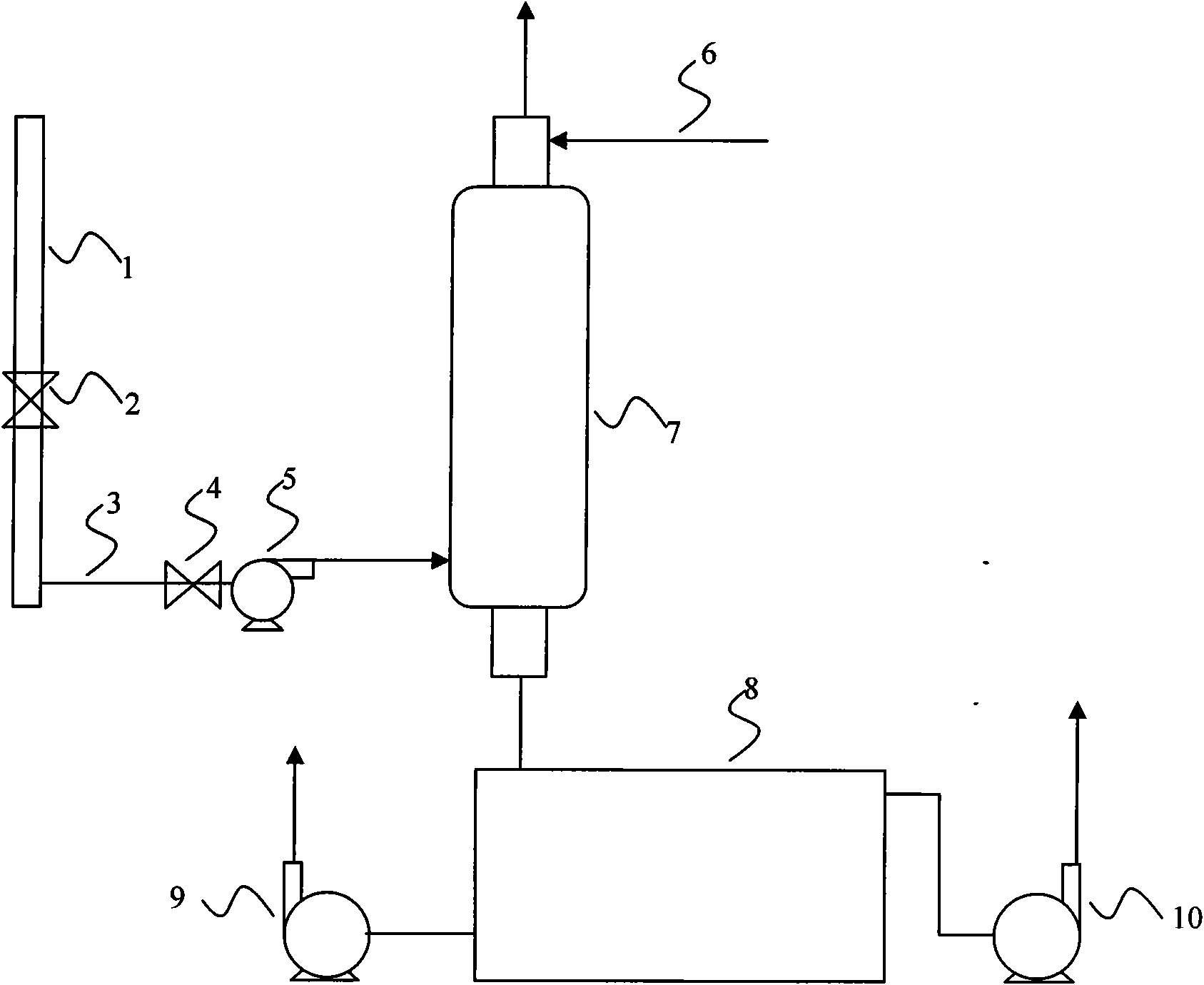

Image

Examples

Embodiment 1

[0017] Roasting furnace: exhaust fan speed 75%, feeding capacity 79t / h

[0018] Waste heat recovery system: heat exchanger flue gas throughput 100%, flue gas inlet temperature 153°C, outlet temperature 20.9°C, feed water temperature 20.9°C, outlet water temperature 76°C, flow rate 450m 3 / h, recovery of alumina 13Kg / h.

[0019] Roasting furnace: exhaust fan speed 81%, feeding capacity 82t / h

[0020] Waste heat recovery system: flue gas throughput of heat exchanger is 95%, flue gas inlet temperature is 157°C, outlet temperature is 23°C, feed water temperature is 23°C, outlet water temperature is 77°C, flow rate is 455m 3 / h, recovery of alumina 12.3Kg / h.

[0021] Roasting furnace: exhaust fan speed 89%, feeding capacity 87t / h

[0022] Waste heat recovery system: flue gas throughput of heat exchanger is 85%, flue gas inlet temperature is 150°C, outlet temperature is 25°C, feed water temperature is 25°C, outlet water temperature is 74°C, flow rate is 458m 3 / h, recovery of al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com