IGBT with improved collector structure

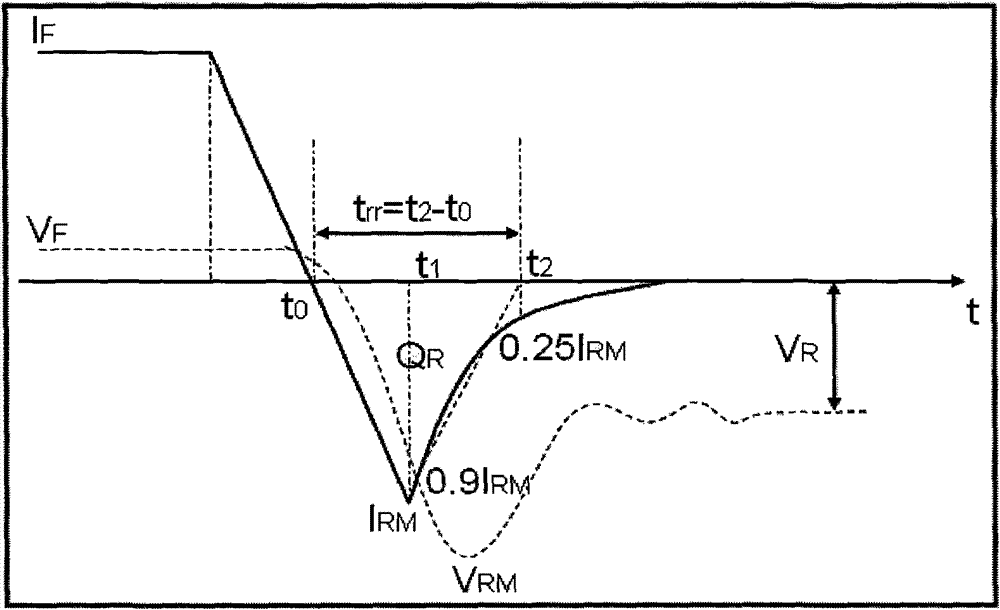

A collector and collector area technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of reducing the impact resistance of devices, increasing on-state loss, increasing reverse recovery hardness, etc., to achieve turn-off loss and endurance Good impact performance, reduced overshoot voltage, and improved impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] like Figure 4As shown: on the section of the insulated gate bipolar transistor IGBT, the N-type semiconductor substrate includes an N-type drift region 7, and the N-type drift region 7 has two opposite main surfaces, and the two opposite main surfaces include the first A main surface 15 and a second main surface 16 . A P-type collector region 8 is formed on the second main surface 16 of the N-type drift region 7, and the P-type collector region 8 includes one or more first regions 11 and one or more second regions 14 , the first region 11 and the second region 14 are both of P conductivity type; the first region 11 surrounds a plurality of second regions 14 or the second regions 14 are alternately adjacent to the first regions 11 . In this embodiment, the second regions 14 are alternately adjacent to the first regions 11 . The first region 11 has a first doping concentration, the second region 14 has a second doping concentration, the first doping concentration of th...

Embodiment 2

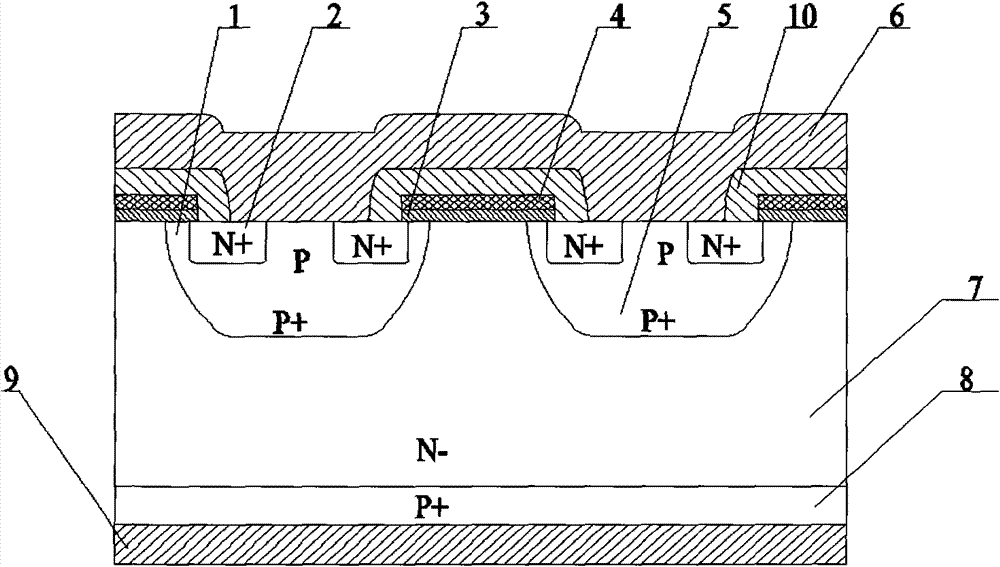

[0027] like Figure 5 Shown: It is an insulated gate bipolar transistor IGBT with a trench-type insulated gate structure. On the cross section of the insulated gate bipolar transistor IGBT, a P base region 1 is arranged on the upper part of the N-type drift region 7 , and the P base region 1 penetrates the N-type drift region 7 . A trench 12 is provided in the P base region 1 , and the trench 12 is located in the P base region 1 and extends deep to the N-type drift region 7 below the P base region 1 . An insulating oxide layer 3 grows on the inner wall of the trench 12 , and conductive polysilicon 4 is deposited in the trench 12 on which the insulating oxide layer 3 grows. An N-type emitter region 2 is arranged above the outer wall of the trench 12 , and the N-type emitter region 2 is in contact with the outer wall of the trench 12 . The notch of the trench 12 is covered by an insulating dielectric layer 10 , and a metallized emitter 6 is also deposited on the first main sur...

Embodiment 3

[0030] like Image 6 As shown: it is an insulated gate bipolar transistor IGBT adopting a planar insulated gate structure, and an N+ collector short-circuit region 13 is provided in the P-type collector region 8 . like Image 6 As shown: the upper part of the N-type drift region 7 is provided with a P base region 1, and the P base region 1 is provided with two N-type emitter regions 2; the adjacent P base region 1 uses an N-type drift region 7 phase isolation. The bottom of the P base region 1 is provided with a P+ base region 5 . The first main surface 15 of the N-type drift region 7 is provided with a planar insulating gate structure; the insulating gate includes an insulating oxide layer 3 and a conductive polysilicon 4; the insulating oxide layer 3 is in phase with the N-type drift region 7 The adjacent P base region 1 is in contact with the corresponding N-type emitter region 2 in the P base region 1 . The insulating oxide layer 3 and the conductive polysilicon 4 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com