Super-gravity revolving bed provided with multi-layer cylindrical rotary liquid distributor

A high-gravity rotating bed and liquid distributor technology, applied in chemical/physical/physicochemical fixed reactors, fractionation, separation methods, etc., can solve the troublesome production and installation, troublesome production and installation of distributors, high initial distribution requirements, etc. problems, to achieve the effect of simple structure, easy equipment and high mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

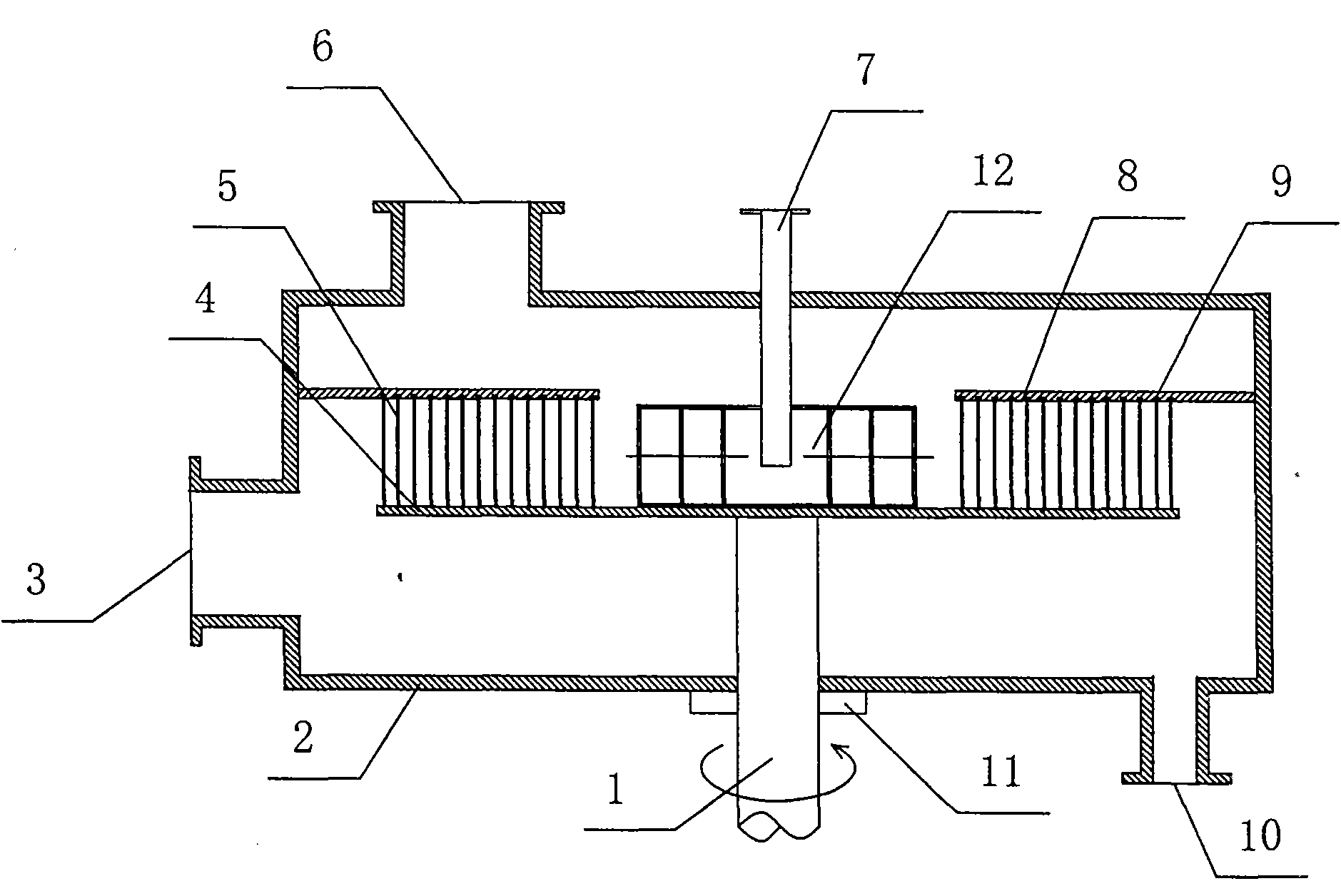

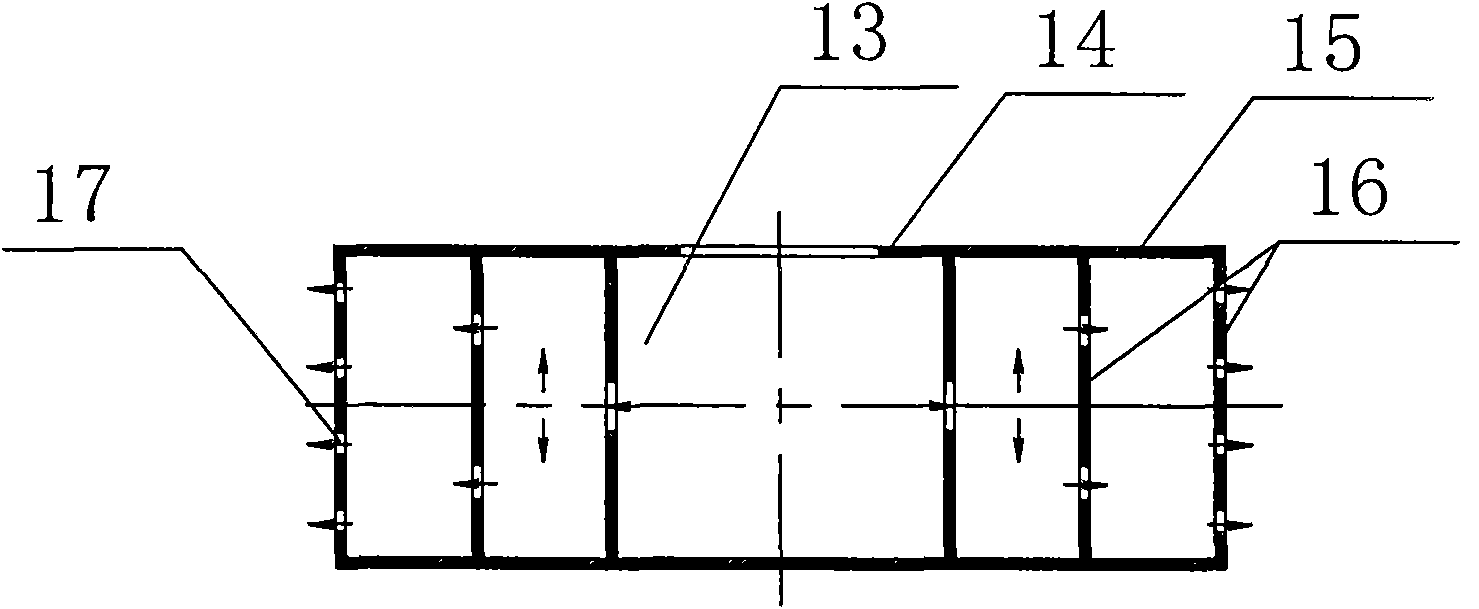

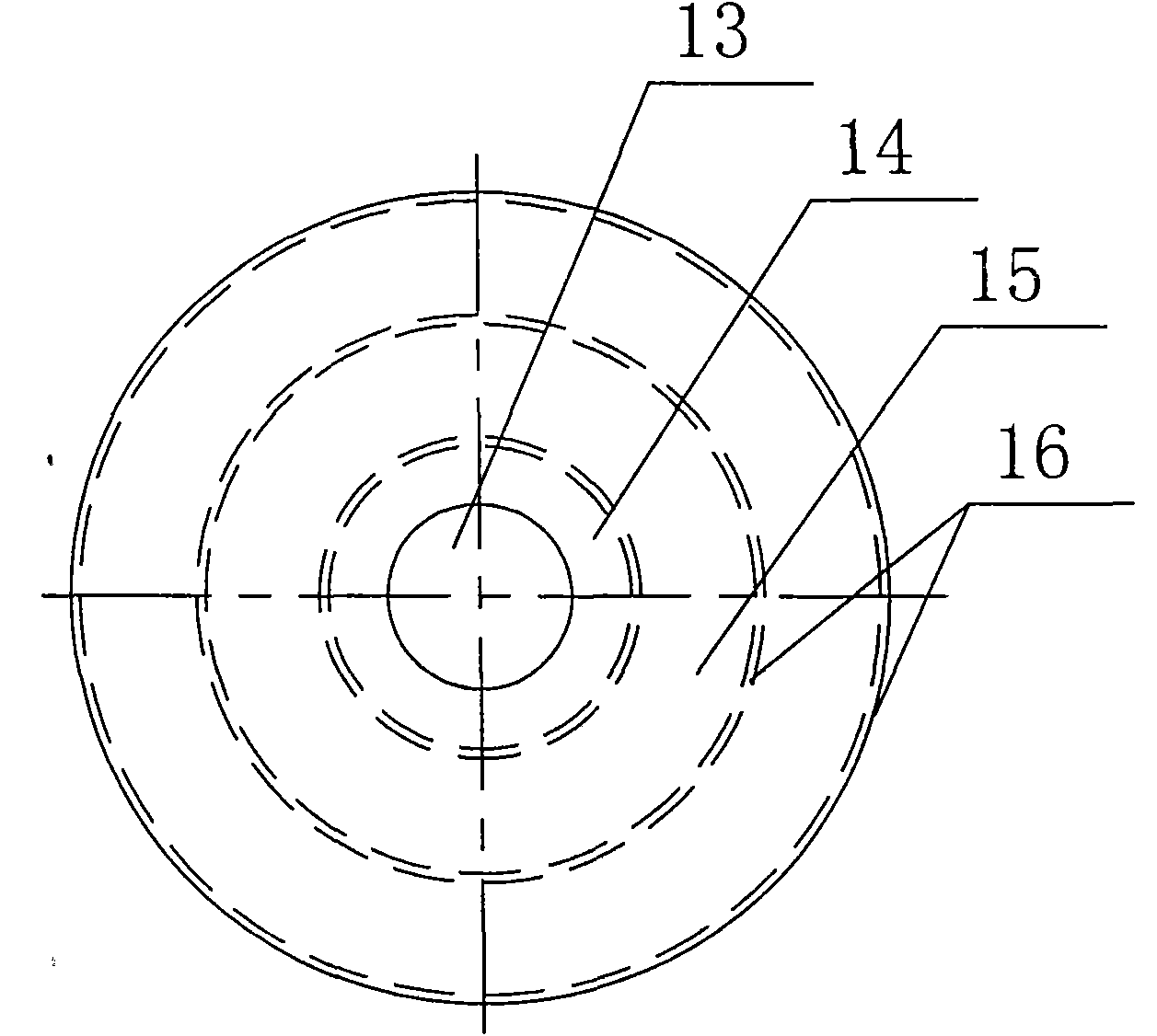

[0024] Such as figure 1 Shown is a single-layer concentric ring-type high-gravity rotating bed device with a multi-layer sleeve-type rotating liquid distributor, which includes a shell 2, a stationary disk 8, a rotating shaft 1, a rotor 4, and a multi-layer cylindrical rotating liquid distributor 器12. The upper end of the casing 2 is provided with a gas outlet 6 and a liquid inlet 7, the lower end of the casing 2 is provided with a gas inlet 3 and a liquid outlet 10, and a mechanical seal 11 is installed at the joint between the rotating shaft 1 and the casing 2. The center of the housing 2 is provided with a rotating shaft 1 and a stationary disk 8, the stationary disk 8 is fixedly connected to the housing 2, the rotating shaft 1 is fixedly connected to a rotor 4, and the rotor 4 is fixedly connected to the multilayer sleeve type liquid distributor 12. The rotor 4 is a concentric ring rotor. A set of concentric moving rings 5 with screen holes of different diameters are provi...

Embodiment 2

[0028] Such as Figure 4 Shown is a single-layer packed high-gravity rotating bed device with a multi-layer sleeve-type rotating liquid distributor. This embodiment is completely the same as Embodiment 1 except that the rotor and sealing structure are different from Embodiment 1. This embodiment adopts Figure 4 In the shown packed rotor, the lower end of the ring-shaped packing layer 18 is fixedly connected to the rotor 4. In order to prevent gas short circuit, a dynamic sealing structure 9 is provided between the upper end of the packing layer 18 and the stationary disk 8, and the gas and liquid flow backward in the rotor 4. After the contact, the gas is discharged from the gas outlet 6 and the liquid phase is discharged from the liquid outlet 10.

Embodiment 3

[0030] Such as Figure 5 Shown is a three-layer concentric-circle counter-current high-gravity rotating bed device with a multi-layer sleeve-type rotating liquid distributor. Each layer of the rotor includes a multi-layer sleeve-type liquid distributor 12 fixedly connected to the rotor. The upper end of the rotor is fixedly connected to the housing 2 and the upper end surface of the stationary disk 8 is provided with a fixedly connected drainage tube 19 and a retaining ring 20, so One end of the drainage tube 19 is communicated with the retaining ring 20, and the lower end of the other end extends into the feed tank 13 of the multilayer sleeve type liquid distributor 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com