Preparation method of mesoporous silicon oxide-based silver catalyst and application thereof in carbon monoxide oxidation

A catalyst and mesoporous technology, applied in the field of inorganic nano-catalytic materials, can solve the problems such as the unsatisfactory CO oxidation and purification effect, achieve good industrial application prospects, convenient operation, simple preparation process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

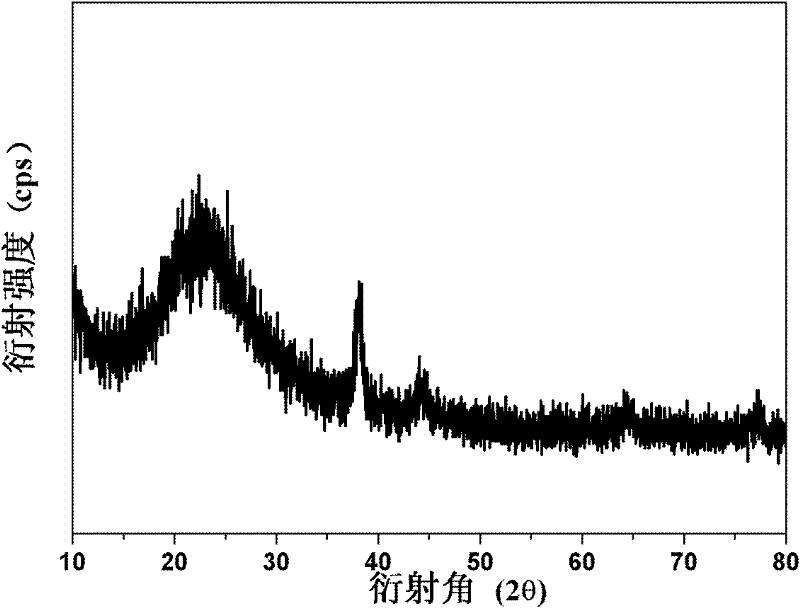

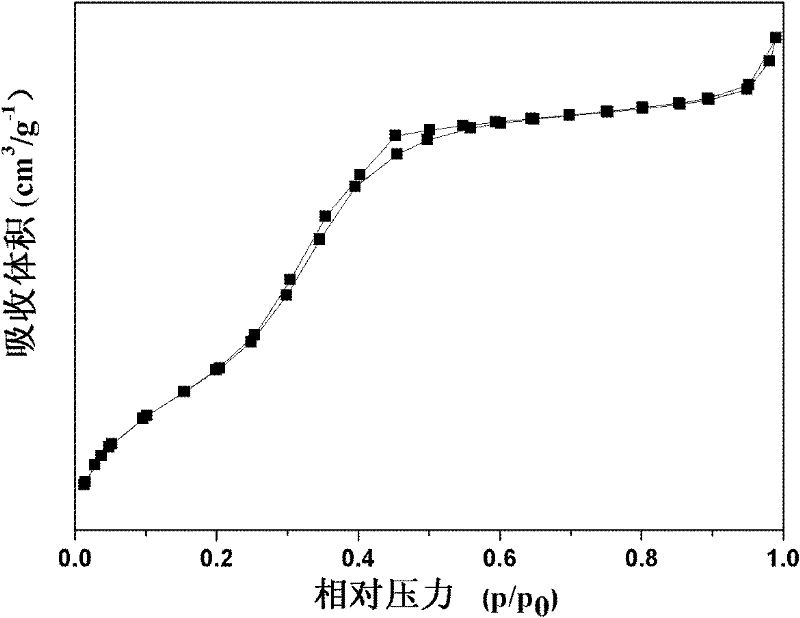

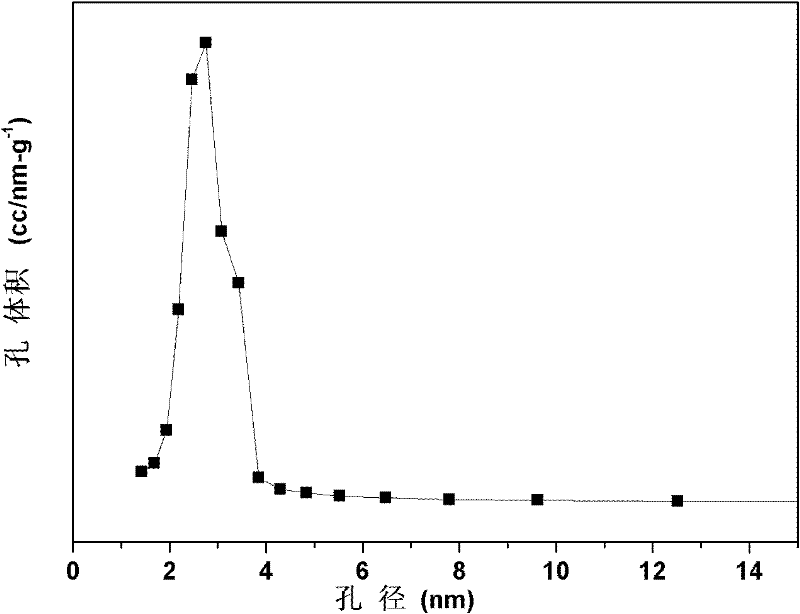

[0026] Add 1.25g of dodecylamine to 10ml of absolute ethanol, stir in a water bath at 25°C, and completely dissolve the dodecylamine until a transparent solution is formed. Add 5ml tetraethyl orthosilicate to the solution, stir for 2h, then add 10ml deionized water to the solution, stir for 1h, then add 0.2ml formaldehyde solution to the solution, stir for 0.5h, then add 0.085g silver nitrate to the solution , The reaction was stirred continuously for 24h. Wash with deionized water, filter, dry in an oven at 100°C for 12h, and calcinate in a muffle furnace at 450°C for 4h in an air atmosphere to obtain Ag / SiO 2 catalyst. Its XRD, N 2 Adsorption-desorption and pore size distribution such as figure 1 , as shown in 2, 3.

[0027] The activity evaluation of the catalyst was carried out in a fixed-bed continuous flow differential reactor. The reactor was a glass U-shaped tube with an inner diameter of 4 mm. The catalyst loading was 200 mg. The feed gas composition: 1% CO (volum...

Embodiment 2

[0029] According to the preparation method of the present invention in Example 1, the order of reagent addition is changed, followed by silver nitrate, water, tetraethyl orthosilicate, and formaldehyde, see Catalytic Activity Figure 4 .

Embodiment 3

[0031] According to the preparation method of the present invention in Example 1, the order of adding reagents is changed, followed by formaldehyde, silver nitrate, water, and tetraethyl orthosilicate, and the catalytic activity is shown in Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com