System and method for leachate treatment in sanitary landfill

A treatment system and treatment method technology, which is applied in the leachate treatment system of garbage sanitary landfills and the field of landfill leachate treatment, can solve the problems of non-removal of ammonia nitrogen, increase of reverse osmosis pressure, inapplicability of landfill leachate, etc. problem, to achieve the effect of stable and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

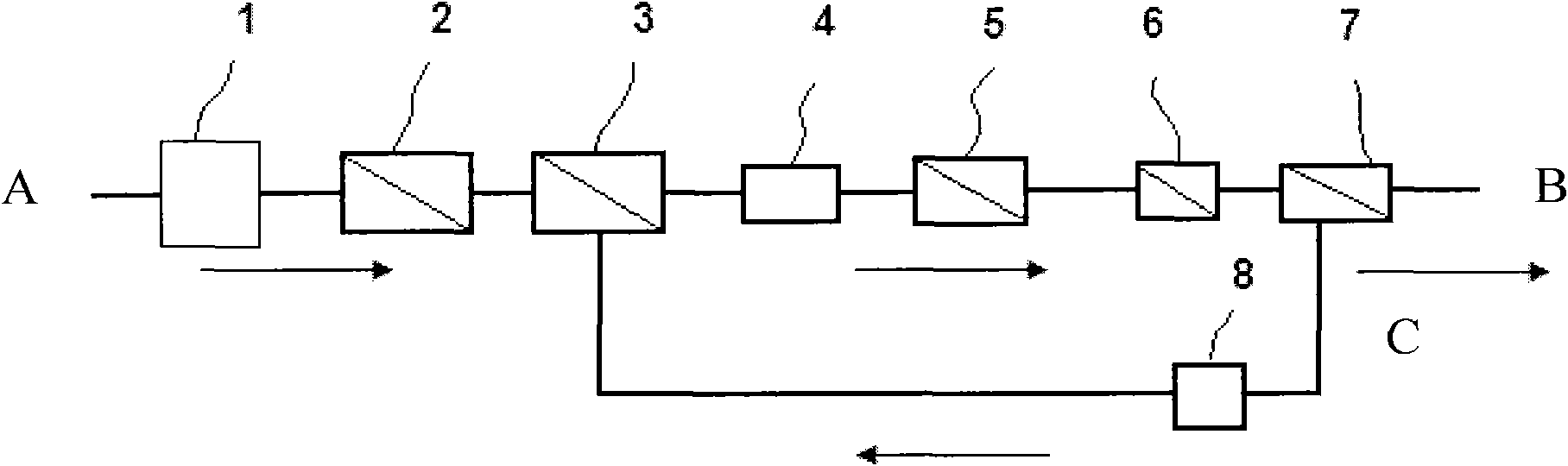

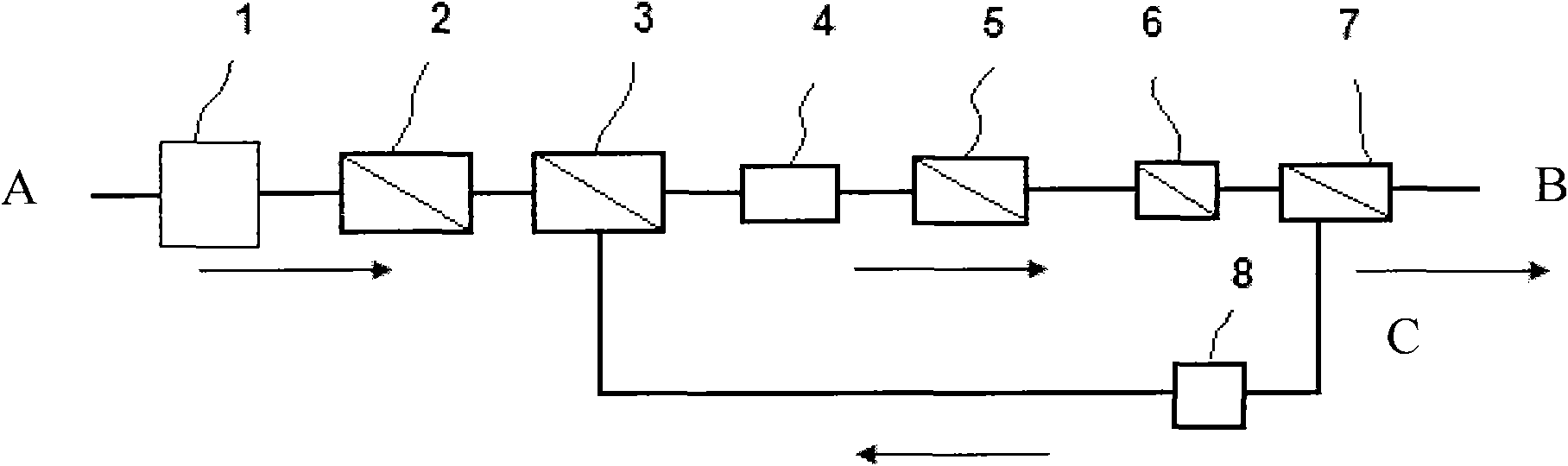

[0028] Present embodiment 1 provides a kind of processing system of leachate of garbage sanitation landfill, as figure 1 As shown, the system includes:

[0029] Adjusting tank, upflow anaerobic reaction tank, anoxic and aerobic biochemical reaction tank, secondary sedimentation tank, coagulation sedimentation tank, submerged ultrafiltration system and nanofiltration system;

[0030] The regulating tank is sequentially connected with the upflow anaerobic reaction tank, the anoxic and aerobic biochemical reaction tank, the secondary settling tank, the coagulation sedimentation tank, the submerged ultrafiltration system and the nanofiltration system. The water outlet is used as a drain; wherein, a submersible mixer is provided in the regulating tank; a stirring device, an aeration device and a reflux pump are provided in the anoxic and aerobic biochemical reaction tank; agent and coagulant aid inlet; the advanced oxidation system is equipped with ultrasonic auxiliary equipment. ...

Embodiment 2

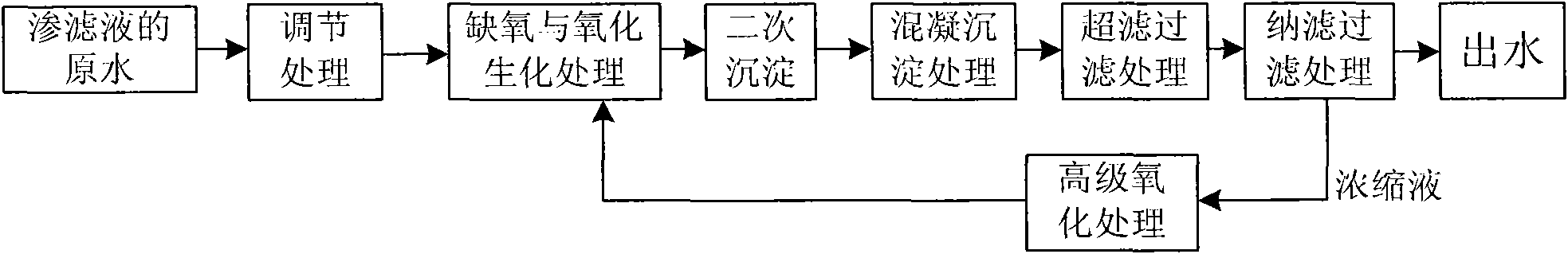

[0038] The embodiment of the present invention provides a kind of treatment method of leachate of garbage sanitary landfill, can utilize the processing system that above-mentioned embodiment 1 provides to process the leachate of garbage sanitary landfill, as figure 2 As shown, the method includes:

[0039] Conditioning treatment: Stir and mix the leachate of the treated garbage sanitary landfill evenly, so that the concentration of pollutants in the leachate after mixing is uniform, and perform anaerobic biochemical reaction treatment on the effluent after conditioning treatment;

[0040] Anaerobic biochemical reaction treatment: Anaerobic biochemical reaction treatment is performed on the effluent after the adjustment treatment, and part of the high-molecular organic matter in the water is decomposed into lower molecular weight organic matter, and anoxic and aerobic biochemical treatment is performed on the effluent treated by the anaerobic biochemical reaction ;

[0041] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com