Sintering and synthesizing method of negative thermal expansion material Zr2P2MO12

A negative thermal expansion material, zr2p2mo12 technology, applied in the field of inorganic non-metallic materials, can solve the problems of sample contamination in the sintering process, time-consuming material preparation, complicated preparation process, etc., achieve high purity, avoid ammonia emission problems, and simple reaction process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Set the high-temperature tube furnace to heat up to the sintering temperature of 1200°C at a rate of 5°C / min:

[0031] will be able to generate Zr 2 P 2 WO 12 Raw material ZrO 2 、WO 3 ,P 2 o 5Weigh it at a molar ratio of 2:1:1, grind it in an agate mortar for 2 hours, and mix the raw materials evenly; put the ground and mixed raw materials in a drying oven for 4 hours, and the temperature of the drying oven is 150°C; The hydraulic machine presses the dried raw material powder into a disc shape with a size of 2cm in diameter and 2mm in thickness. After pressing, put it into a sealed bag quickly to prevent the sample from absorbing water and pulverize it for later use; finally put it in a high temperature that has been heated to 1200°C Sinter in a tube furnace for 80min, take it out after sintering, and let it cool naturally at room temperature.

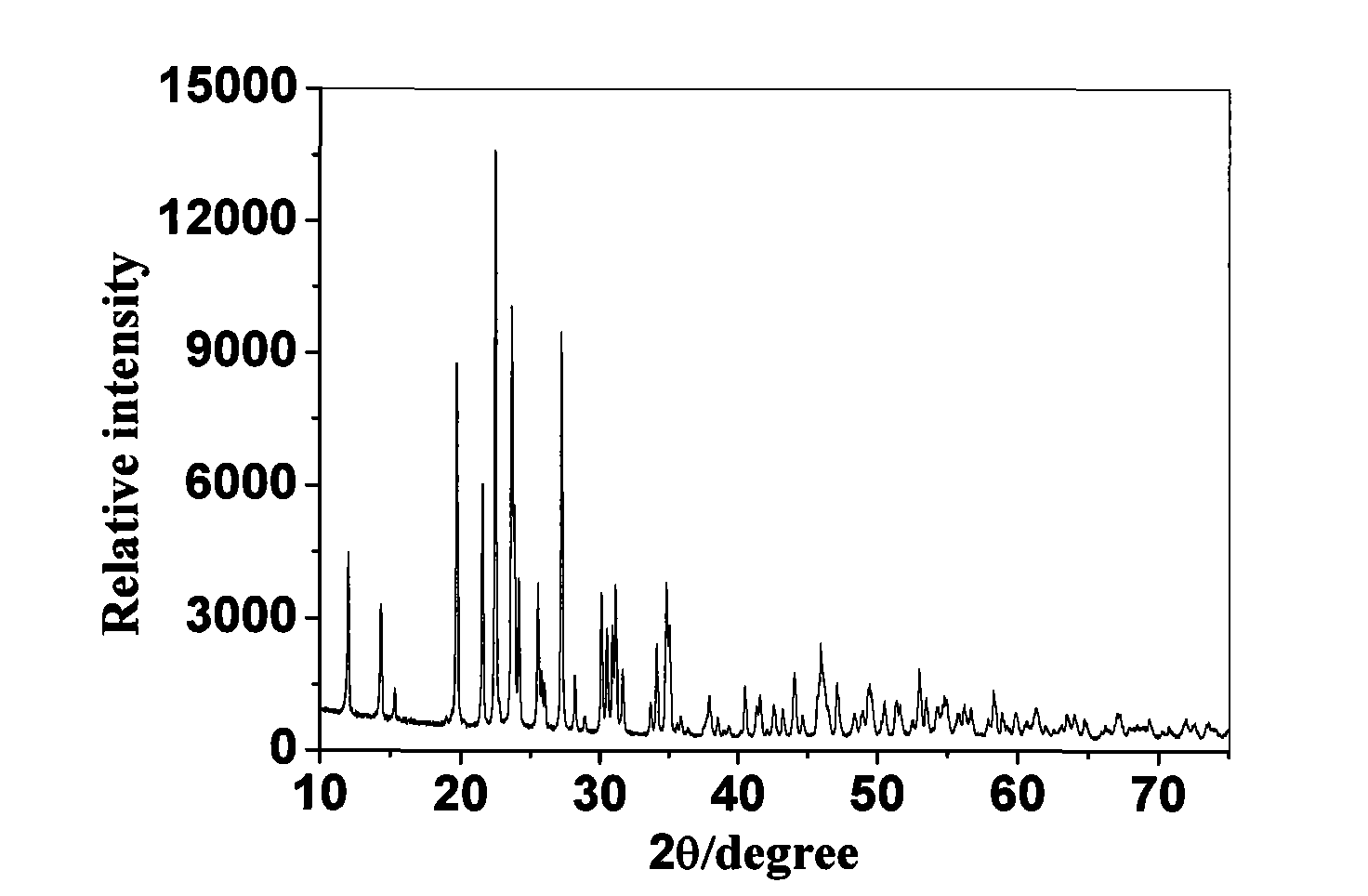

[0032] For the X-ray diffraction phase analysis corresponding to the product, see figure 1 , figure 1 The XRD results...

Embodiment 2

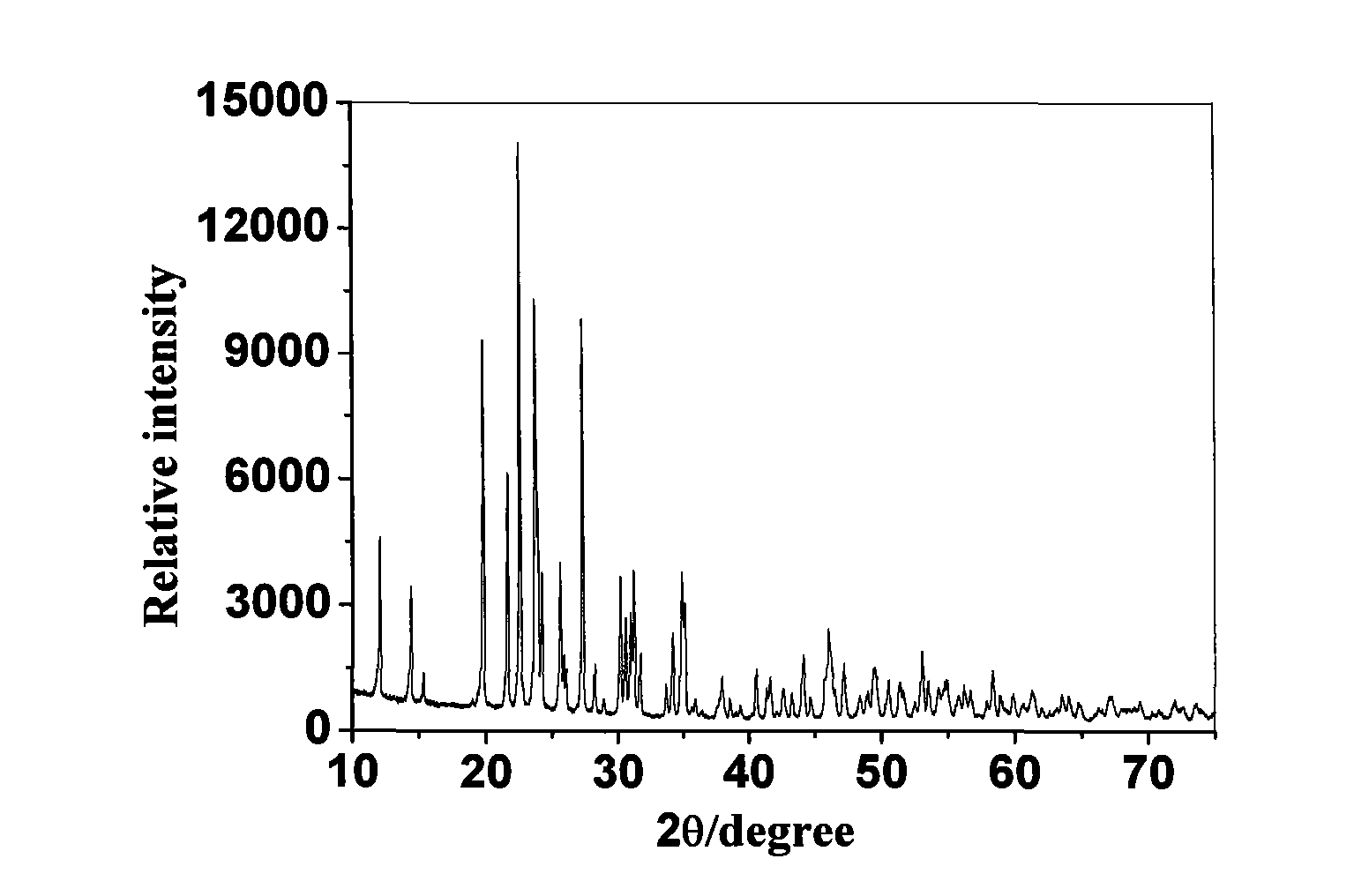

[0034] The difference from Example 1 is: a high-temperature tube furnace is set to heat up to a sintering temperature of 1300° C., and the sintering time is 1 h; ZrO 2 : WO 3 :P 2 o 5 The molar ratio of Zr is 2:1.1:1.1; the drying temperature is 160°C, and the drying time is 3h+40min; the formed Zr 2 P 2 WO 12 For the corresponding X-ray diffraction phase analysis see figure 2 , figure 2 The XRD results showed the formation of pure Zr 2 P 2 WO 12 Mutually.

Embodiment 3

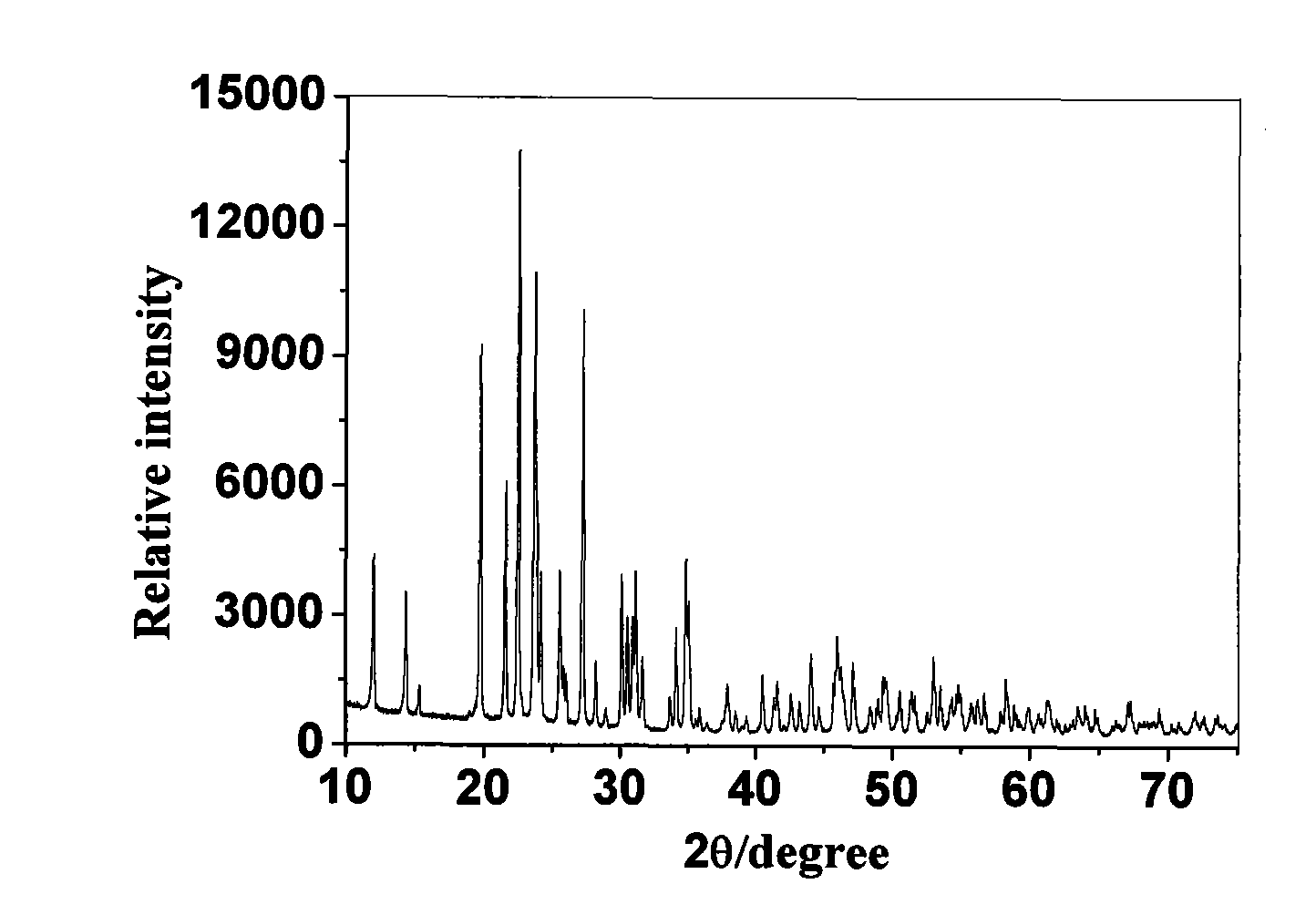

[0036] The difference from Example 1 is that a high-temperature tube furnace is set to heat up to a sintering temperature of 1300°C, and the sintering time is 2h; ZrO 2 : WO 3 :P 2 o 5 The molar ratio is 2:1.1:1.1; the drying temperature is 170°C, and the drying time is 3h+20min; the formed Zr 2 P 2 WO 12 For the corresponding X-ray diffraction phase analysis see image 3 , image 3 The XRD results showed the formation of pure Zr 2 P 2 WO 12 Mutually.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com