Preparation method of homopiperazine

A technology of homopiperazine and diformyl homopiperazine, which is applied in the direction of organic chemistry, can solve the problems of high cost of raw materials and solvents, no obvious price advantage, and only 21% yield, and achieve easy recycling and reuse. Application value, effect of simple equipment

Inactive Publication Date: 2010-11-24

SHANGHAI RECORD PHARM CO LTD +1

View PDF2 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

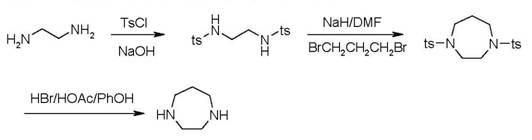

The NaH / DMF system was used in the second step cyclization reaction, and a phase transfer catalyst was added to complete the cyclization reaction under relatively mild conditions. The crude product could be directly subjected to the next step reaction; Sulfonyl group, yield can reach 91%; This route raw material is easy to get, and operation is simple, and yield is higher, is the synthetic route of homopiperazine and homopiperazine derivative commonly used; The requirements are very high, and the price advantage is not obvious

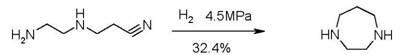

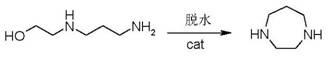

The raw materials of this route are simple and easy to obtain, but the reaction temperature is as high as 150-400 °C, the process is complicated, and the yield is only 21%.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a preparation method of homopiperazine, comprising the following steps of firstly, obtaining N-(2-formylethyl) formamide by carrying out reflux reaction on ethylenediamine and formylation reagent, wherein the molar ratio of the ethylenediamine to the formylation reagent is 1:2-4; secondly, obtaining 1,4-dicarboxy homopiperazine by reacting the N-(2-formylethyl) formamide with 1,3-propane dihalide under the alkaline condition, wherein the molar ratio of the N-(2-formylethyl) formamide to the 1,3-propane dihalide is 1:1.0-1.2; and thirdly, obtaining the homopiperazine by removing formyl of the 1,4-dicarboxy homopiperazine in alcohol hydrochloride solution. The invention has the advantages of cheap raw materials, simple synthesis technology, mild protection conditions, mild technological conditions, simple equipment and easy recovery and reuse of used solvent in the whole process.

Description

The preparation method of homopiperazine technical field The invention belongs to the field of medicinal chemistry, in particular to a preparation method of homopiperazine. Background technique Nitrogen-containing heterocyclic homopiperazine, also known as 1,4-diazepane, is an important intermediate in drug synthesis, and the dinitrogen atoms contained in it can react with many organic compounds. Homopiperazine can be used to synthesize drugs such as homopiperazine hydrochloride, cyclizine, carbamazepine, quinolones and chlorcyclazine. According to the report of ArmigerH et al. [1], the antihistamine activity of drugs such as cyclizine and homochlorocyclazine was significantly enhanced after using homopiperazine instead of piperazine to synthesize drugs such as cyclizine and homochlorocyclazine. Ziegler [2] et al.'s research on the correlation between drug activity and structure shows that the presence of homopiperazine groups can significantly improve the activity of rel...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07D243/08

Inventor 孙靖吴晓东张芳江

Owner SHANGHAI RECORD PHARM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com