Method for separating and purifying curcin from seeds of jatropha curcas

A technology for separation and purification of toxic proteins, applied in the field of separation and purification of plant natural proteins, can solve the problems of long process cycle, increased column volume cost, insufficient scalability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The first step: prepare the crude extract of Curcin. The crude extract of Curcin was prepared according to the method disclosed in prior art 1.

[0040] The second step: desalting and buffer exchange. First use buffer A, that is, Tris-HCl buffer solution with a Tris concentration of 35mM and a pH of 8.2 for column equilibration, equilibrate for 5 column volumes, then load the crude extract of Curcin as a sample, and collect the first sample after loading. 280nm absorption peak components. Among them, the instrument uses AKTA purifier UPC 10 (product of General Electric Medical Group), the filler uses Sephadex G 25 superfine filler, the flow rate is 200cm / h, and the detector wavelength is 280nm.

[0041] The third step: anion exchange chromatography. First use buffer A (the ratio, concentration and pH are the same as the previous step) for column equilibration, equilibrate for 5 column volumes, then load the components collected in the desalting and buffer exchange st...

Embodiment 2

[0045] The first step: prepare the crude extract of Curcin. The crude extract of Curcin was prepared according to the method disclosed in prior art 1.

[0046] The second step: desalting and buffer exchange. First use buffer A, that is, Tris-HCl buffer with a Tris concentration of 20mM and a pH of 8.0 for column equilibration, equilibrate for 5 column volumes, then load the crude extract of Curcin as a sample, and collect the first 280nm absorption peak components. Wherein the flow rate is 150cm / h.

[0047] The third step: anion exchange chromatography. First use buffer A (the ratio, concentration and pH are the same as the previous step) for column equilibration, equilibrate for 5 column volumes, then load the components collected in the desalting and buffer exchange steps as samples, and collect the breakthrough after loading Components (components not bound to fillers). Wherein the flow rate is 150cm / h.

[0048] Step Four: Dilution. The fraction collected in the thir...

Embodiment 3

[0052] The first step: prepare the crude extract of Curcin. The crude extract of Curcin was prepared according to the method disclosed in prior art 1.

[0053] The second step: desalting and buffer exchange. First use buffer A, that is, Tris-HCl buffer with a Tris concentration of 40 mM and a pH of 8.0 for column equilibration, equilibrate for 5 column volumes, then load the crude extract of Curcin as a sample, and collect the first 280nm absorption peak components. Wherein the flow rate is 150cm / h.

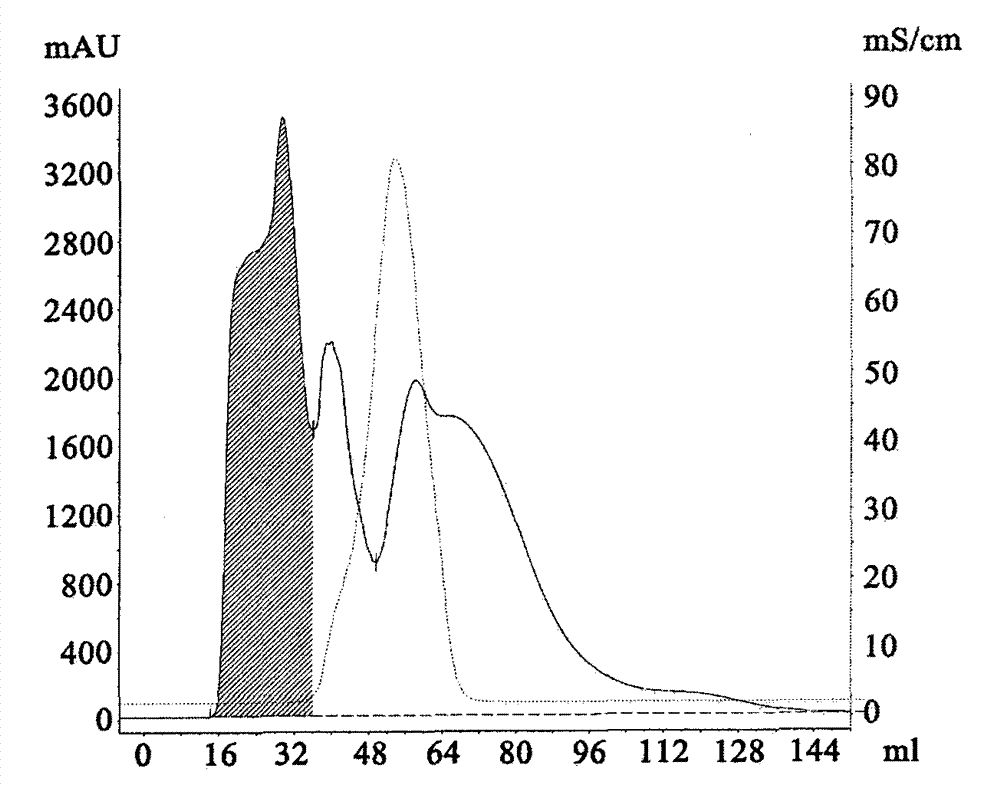

[0054] For the chromatographic peak pattern (or chromatogram) corresponding to this step, see figure 1 . See the specific collection location figure 1 In the middle shaded part, the electrophoresis results of the collected fractions are shown in Figure 4 Lane 3.

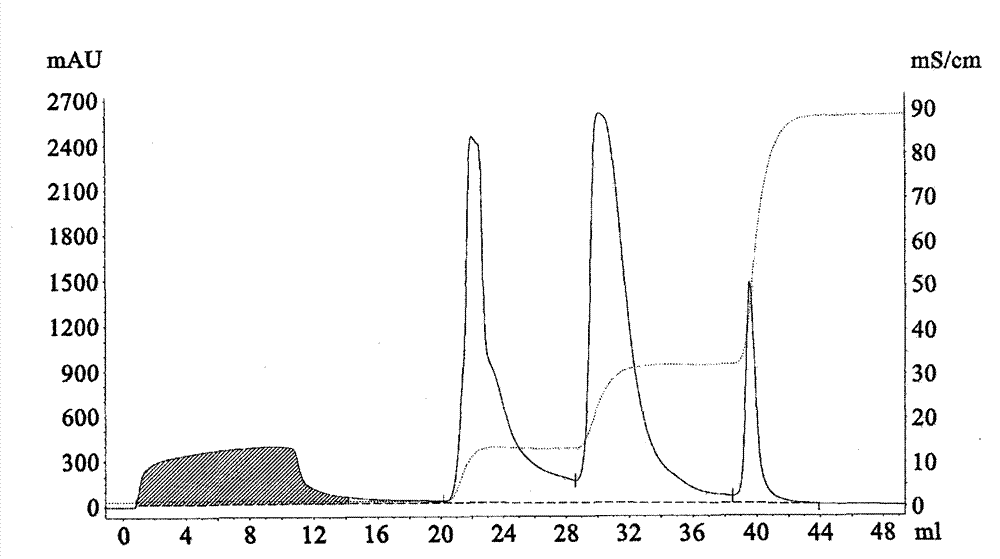

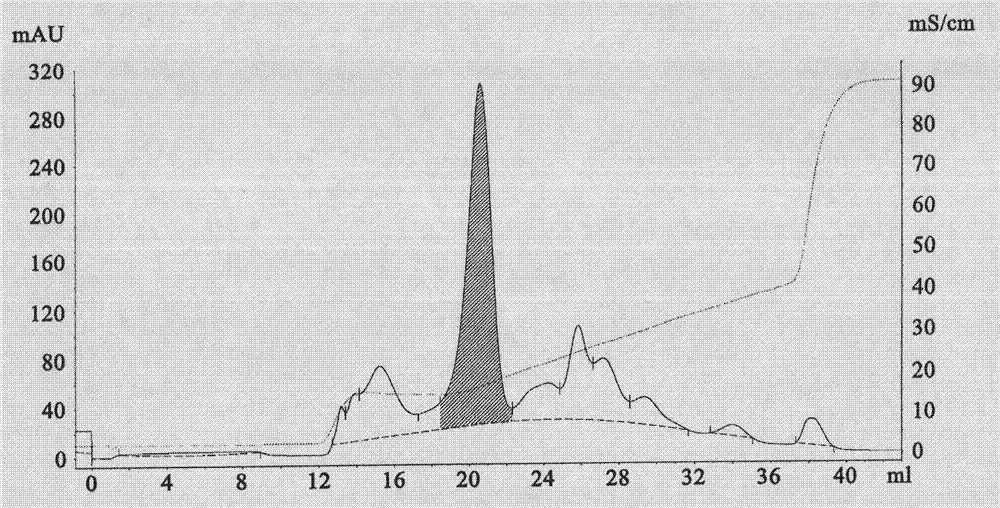

[0055] The third step: anion exchange chromatography. First use buffer A (the ratio, concentration and pH are the same as the previous step) for column equilibration, equilibrate for 5 column volumes, then lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com