Deepwater carrying cable

A load and cable technology, applied in the direction of insulating cables, cables, circuits, etc., to achieve the effect of small size, thin insulation layer and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

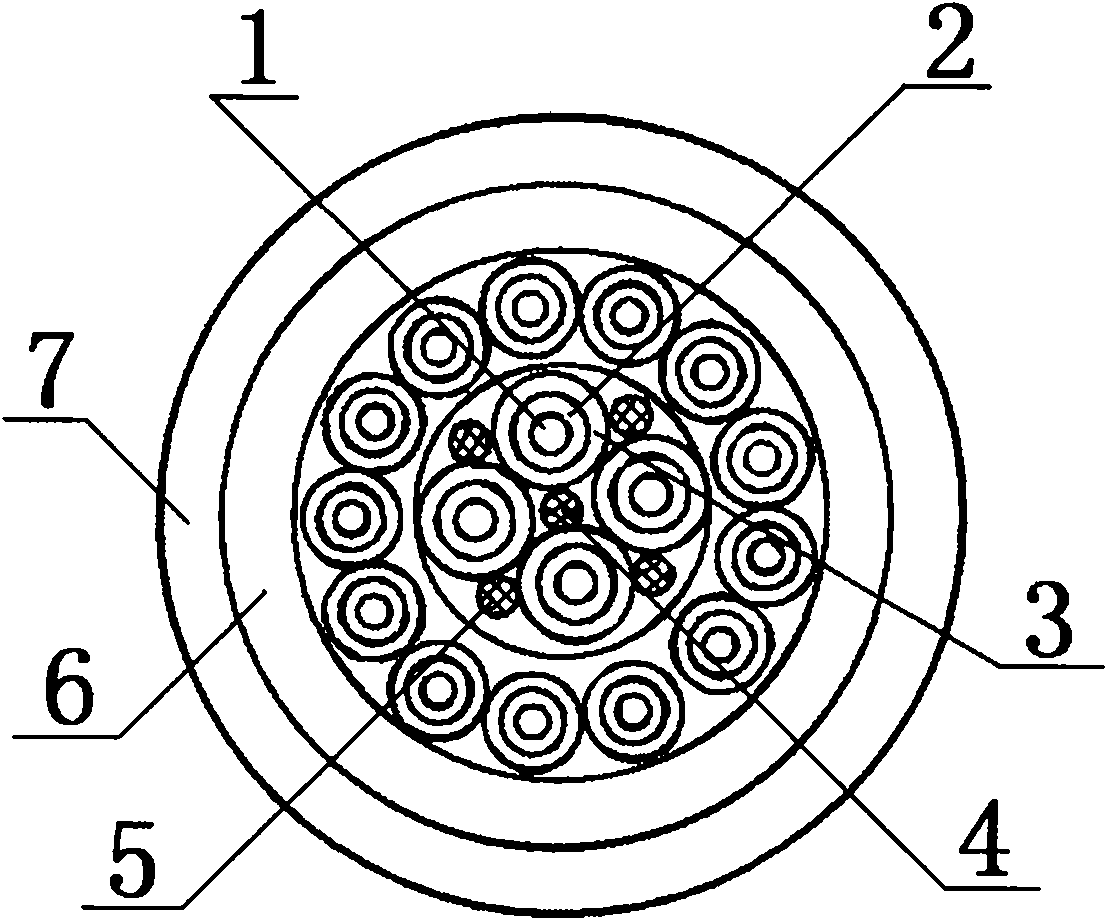

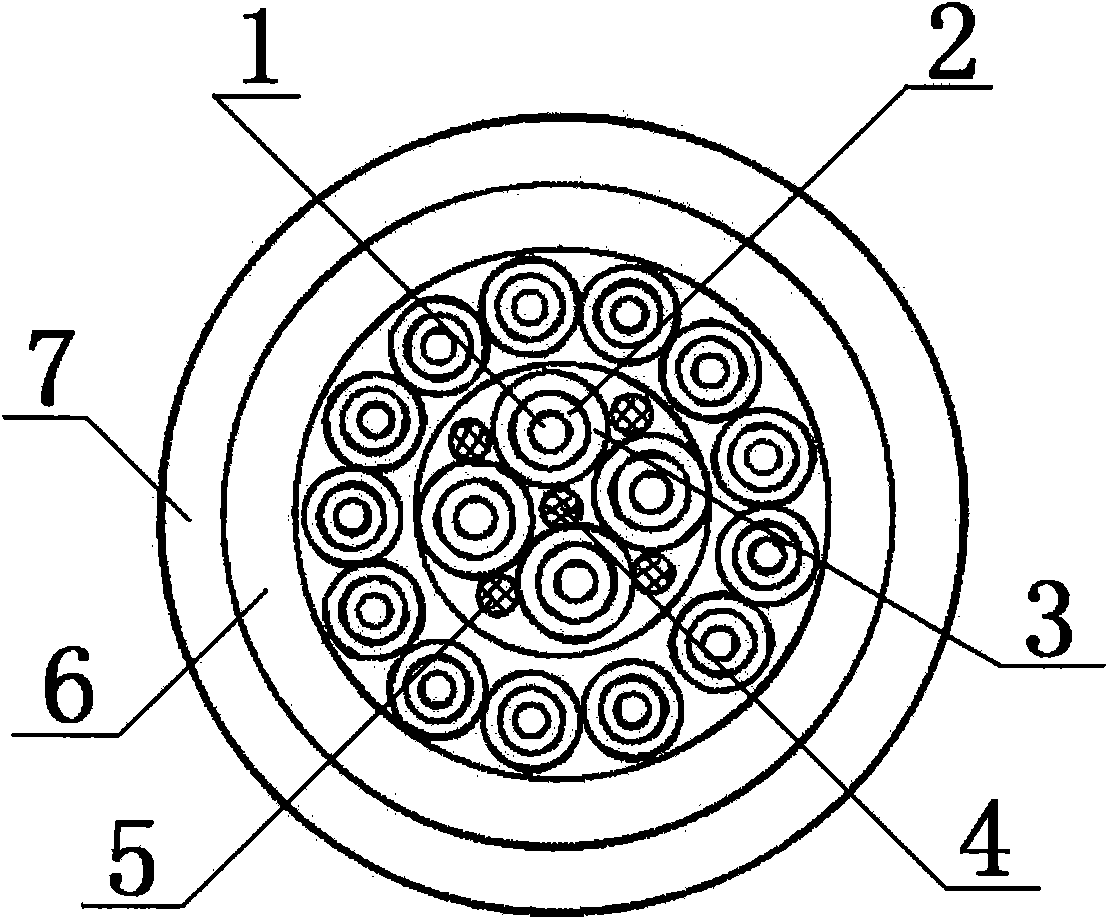

[0012] Embodiment 1, it includes a core cable and a sheath layer 7, the core cable is composed of three or more conductive core wires, and a water-blocking and tensile core rope 4 is arranged in the center of the core cable, and the conductive Water-blocking and tensile ropes 5 are filled between the core wires; a conductive core wire layer consisting of 5 or more conductive core wires distributed in a circle is arranged around the core cable; The outer periphery is provided with a water-blocking and tensile layer 6 and a sheath layer 7 in sequence from the inside to the outside. The water-blocking and tension-resistant rope 4, the water-blocking and tension-resistant rope 5, and the water-blocking and tension-resistant layer 6 can all be interwoven with water-blocking yarn and aramid yarn. treatment can effectively prevent the penetration of water vapor; the aramid yarn has high mechanical strength, especially the tensile strength is superior, and the interweaving of the wate...

Embodiment 2

[0013] Embodiment 2, the conductive core wire of the present invention is composed of three parts: a conductor 1, an insulating layer 2 and a waterproof layer 3, and the conductor 1 is preferably a silver-plated copper conductor, so as to improve the corrosion resistance and mechanical strength of the conductor And improve its welding performance to meet the requirements of vibration occasions; the outer layer of the conductor 1 is an insulating layer 2 that is separately extruded and molded with fluoroplastic F40. The known fluoroplastic F40 is a copolymer of ethylene and tetrafluoroethylene , the specific gravity of the material is light, and it is a thermosetting material. Its application not only improves the reliability of conduction, but also makes the wire flexible, small in size, light in weight, and easy to install and use. The outer layer of the insulating layer 2 is provided with a waterproof layer 3 interwoven with water-blocking yarn and aramid yarn to ensure the w...

Embodiment 3

[0014] Embodiment 3, the present invention can also use part of the conductive core wires in the conductive core wires that constitute the core cable and the conductive core wires that make up the conductive core wire layer as power wires, and the other multiple conductive core wires are used as signal wires. The power line and the signal line are made into one cable, so that the space occupied by the cable can be effectively reduced, and the assembly efficiency can be improved. refer to figure 1 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com