Two-tower stripping treatment method for sewage in coal chemical engineering equipment

A technology of coal chemical industry and stripping, applied in the field of coal chemical industry, can solve the problems of unsatisfactory acid sewage treatment effect, etc., and achieve the effect of avoiding separate treatment, reducing discharge, and having large operation flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

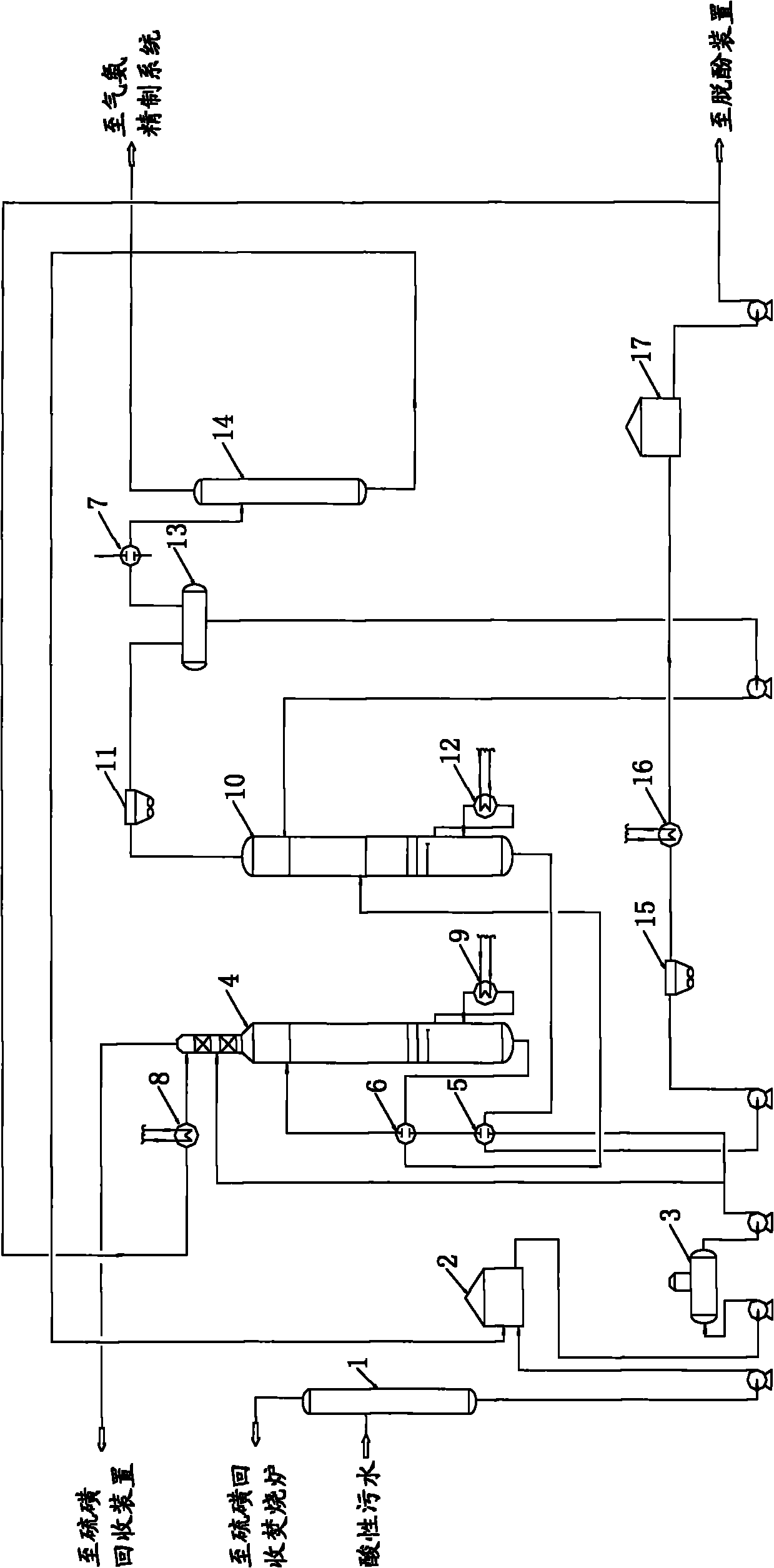

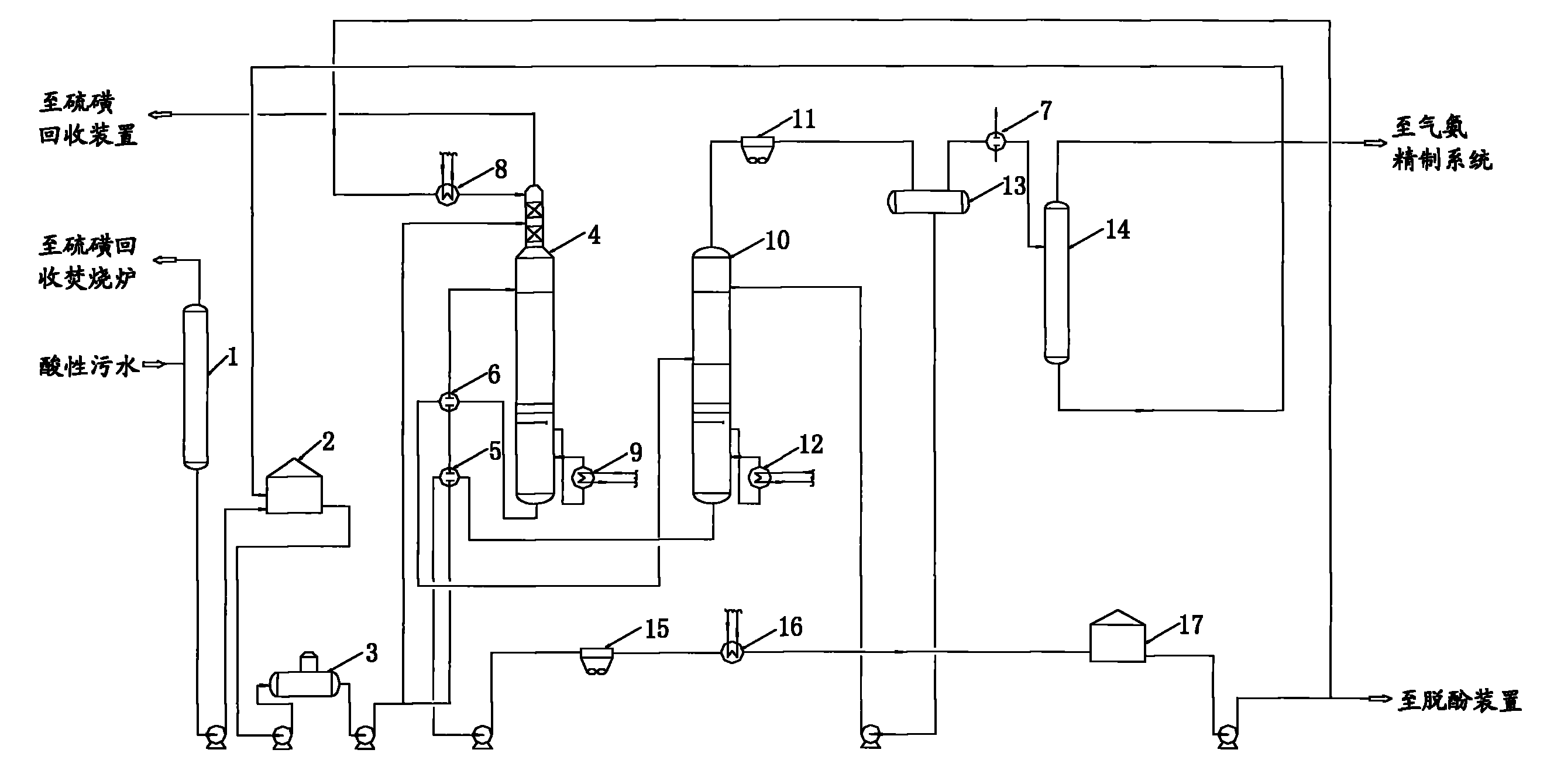

[0026] Acid sewage with high sulfur and ammonia content from coal-to-liquids plant, in which the concentration of hydrogen sulfide is 48000ppm and the concentration of ammonia is 31000ppm. The sewage first enters the sewage degassing tank 1 to remove oil and gas, and the removed oil and gas are discharged to the incinerator of the sulfur recovery device. Under the control of the liquid level, the sewage at the bottom of the tank is pumped into the sewage storage tank 2, where it stands for a long time to remove most of the oil in the water, and then pumped to the degreaser 3 to further remove tiny oil droplets in the water.

[0027] The acidic sewage after oil removal is divided into two parts by the pump under the flow control, and the acidic sewage accounting for 47% of the total weight of the sewage is used as the cold feed into the upper packing section of the first stripper 4, and the remaining acidic sewage is passed through the sewage - After the purified water heat exc...

Embodiment 2

[0032] Acid sewage with high sulfur and ammonia content from coal-to-liquids plant, in which the concentration of hydrogen sulfide is 11000ppm and the concentration of ammonia is 18000ppm. The sewage first enters the sewage degassing tank 1 to remove oil and gas, and the removed oil and gas are discharged to the incinerator of the sulfur recovery device. Under the control of the liquid level, the sewage at the bottom of the tank is pumped into the sewage storage tank 2, where it stands for a long time to remove most of the oil in the water, and then pumped to the degreaser 3 to further remove tiny oil droplets in the water.

[0033] The acidic sewage after oil removal is divided into two parts by the pump under flow control, among which the acidic sewage accounting for 10% of the total weight of the sewage enters the packing section of the first stripping tower as cold feed, and the rest is exchanged by sewage-purified water After being heated to 118°C by the tank 5, it exchan...

Embodiment 3

[0038] Acid sewage with high sulfur and ammonia content from coal-to-liquids plant, in which the concentration of hydrogen sulfide is 54000ppm and the concentration of ammonia is 35000ppm. The sewage first enters the sewage degassing tank 1 to remove oil and gas, and the removed oil and gas are discharged to the incinerator of the sulfur recovery device. Under the control of the liquid level, the sewage at the bottom of the tank is pumped into the sewage storage tank 2, where it stands for a long time to remove most of the oil in the water, and then pumped to the degreaser 3 to further remove tiny oil droplets in the water.

[0039] The acidic sewage after oil removal is divided into two parts by the pump under flow control, and the acidic sewage accounting for 47% of the total weight of the sewage enters the packing section of the first stripper 4 as cold feed, and the remaining acidic sewage is passed through the sewage- After the purified water heat exchanger 5 is heated to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com