Method for separating methyl acetate-methanol-water by adopting extractive distillation separation method with two-solvent lateral feed

A technology of methyl acetate, extraction and rectification, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of complex processes, high energy consumption, and large waste water discharge, and achieve simple process steps. , low energy consumption and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

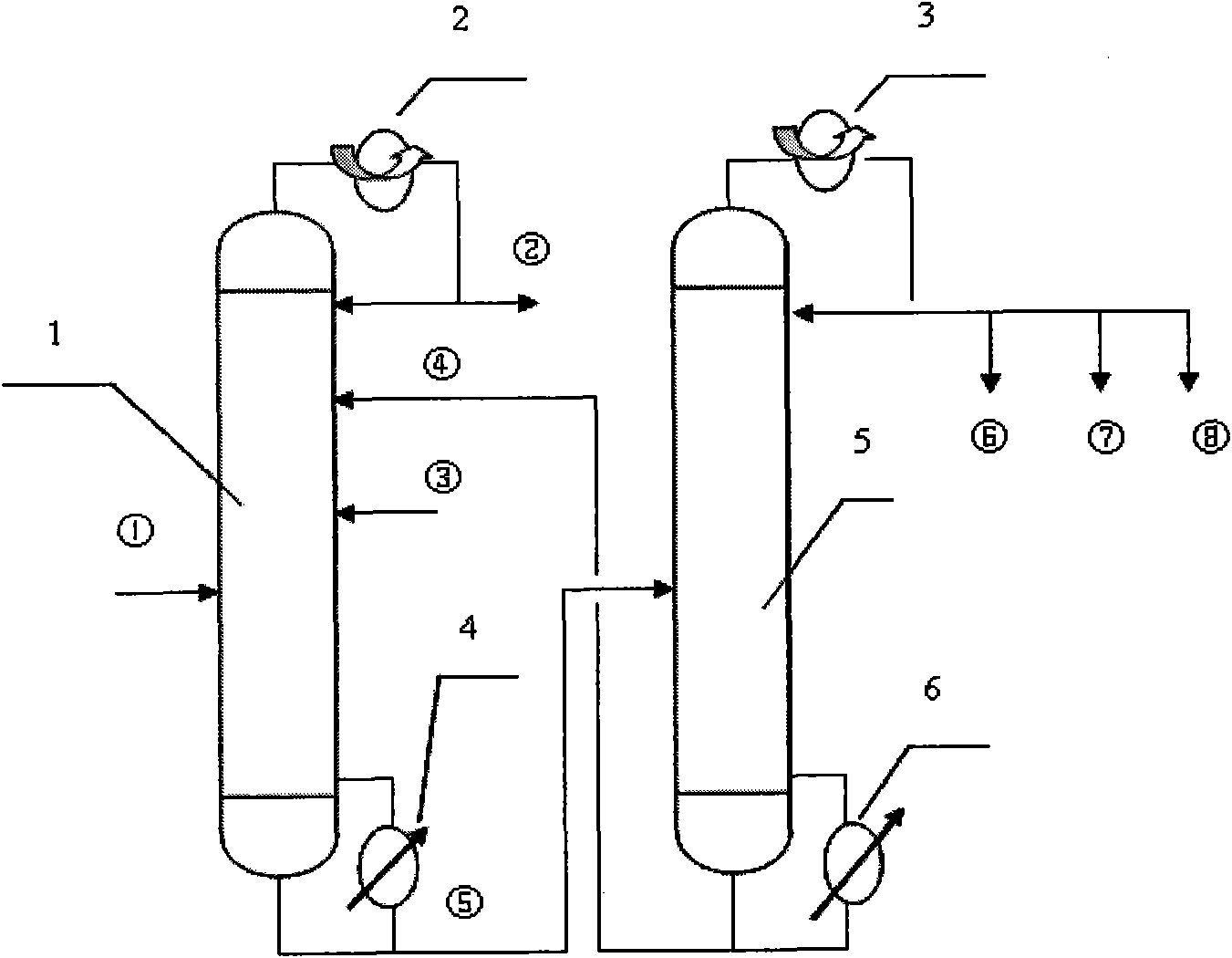

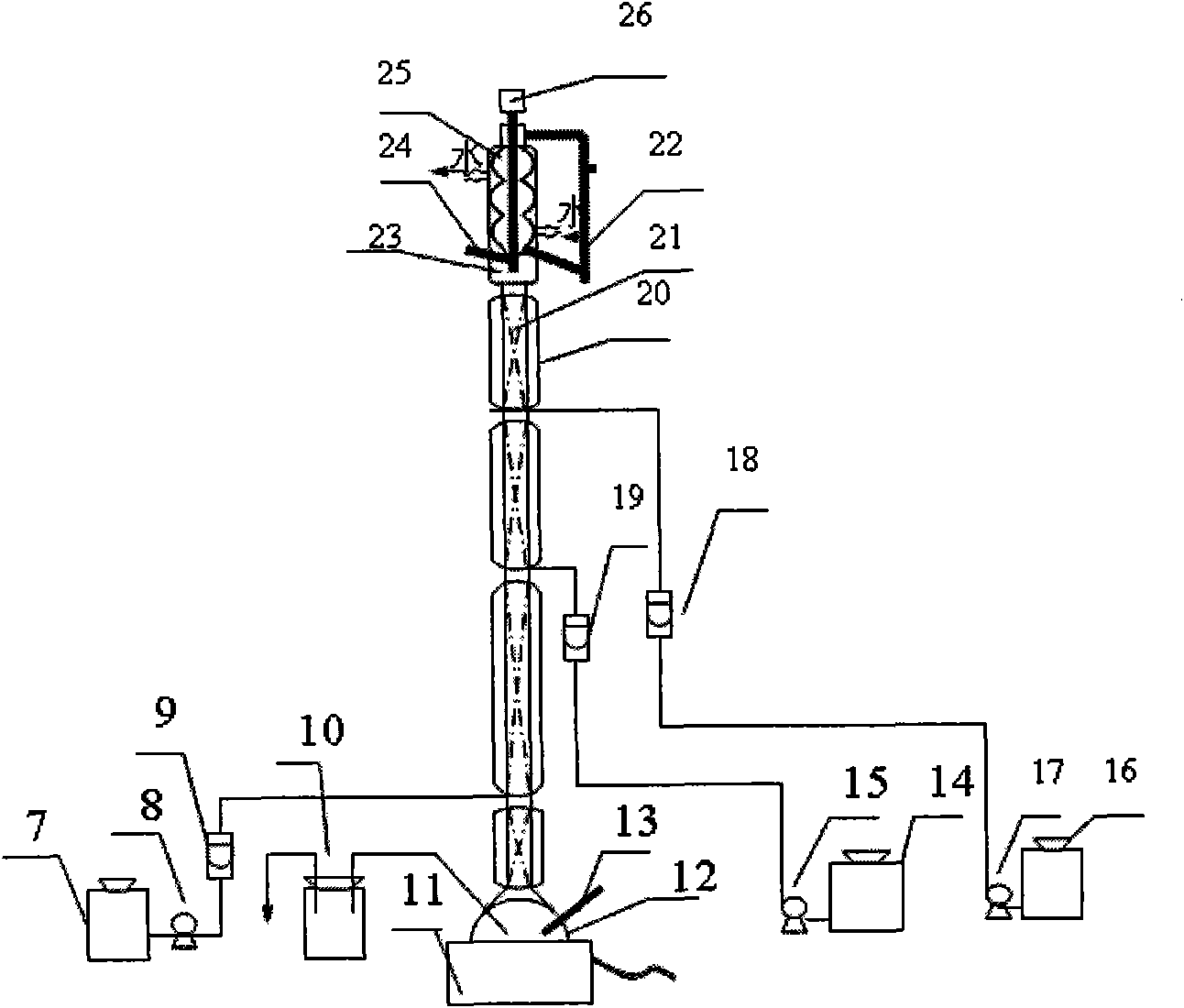

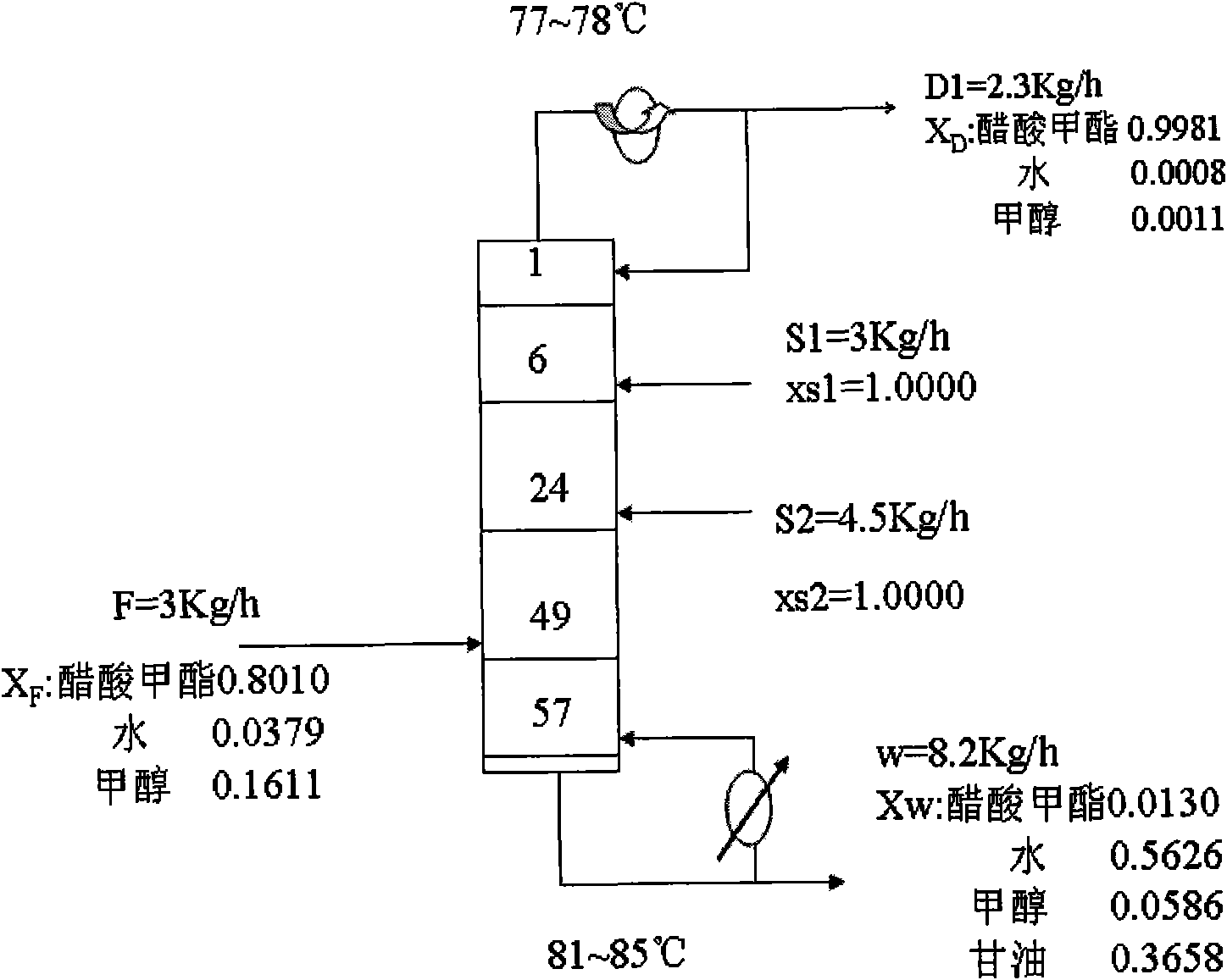

[0023] Embodiment 1: The extraction process and experimental equipment of the two strands of side feed are referred to respectively figure 1 and figure 2 , figure 2 Among them, 7 is the raw material storage tank, 8 is the pump, 9 is the glass rotameter, 10 is the storage tank, 11 is the electric heating jacket, 12 is the tower kettle, 13 is the tower kettle thermometer, 14 is the storage tank, 15 is the pump, and 16 is the storage tank , 17 is the pump, 18 and 19 are glass rotor flowmeters, 20 is glass fiber cotton and jacket, 21 is packing, 22 is return pipe, 23 is return port, 24 is tower top thermometer, 25 is condenser, 26 electromagnetic Great. Using the methyl acetate-methanol-water mixture provided by Yangzi Petrochemical Co., Ltd. as the raw material, it was analyzed by HP chromatography. image 3 In, the composition in the figure is the mass content. The raw material liquid is extracted and separated by two side feed extraction towers, the temperature at the top...

Embodiment 2

[0024] Embodiment 2, refer to figure 1 , figure 2 , using the methyl acetate-methanol mixture (50-55% methyl acetate, 45-50% methanol) provided by Yangzi Petrochemical Company as raw material, the raw material was Figure 5 Middle rectification and extraction are integrated and separated, and more than 99.5% of methyl acetate can be obtained at the top, with a yield of more than 93%. See Figure 5 shown.

Embodiment 3

[0025] Embodiment 3 is basically the same as Embodiment 1, but wherein the extractant adopts S2 water and S1 glycerol; S1:S2=0.5:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com