Preparation method of dihydric phenol di(dialkyl phenyl organic phosphate)

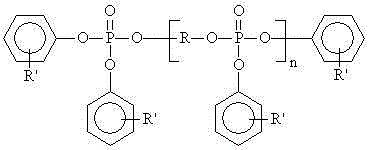

A technology of phenyl phosphate and dihydric phenol is applied in the field of preparation of dihydric phenol bis[bis(2,6-dimethyl)phenyl phosphate], which can solve the problem of increasing the difficulty of product purification, many side reactions, etc. problems, to achieve the effect of reducing environmental protection treatment costs, good environmental protection, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

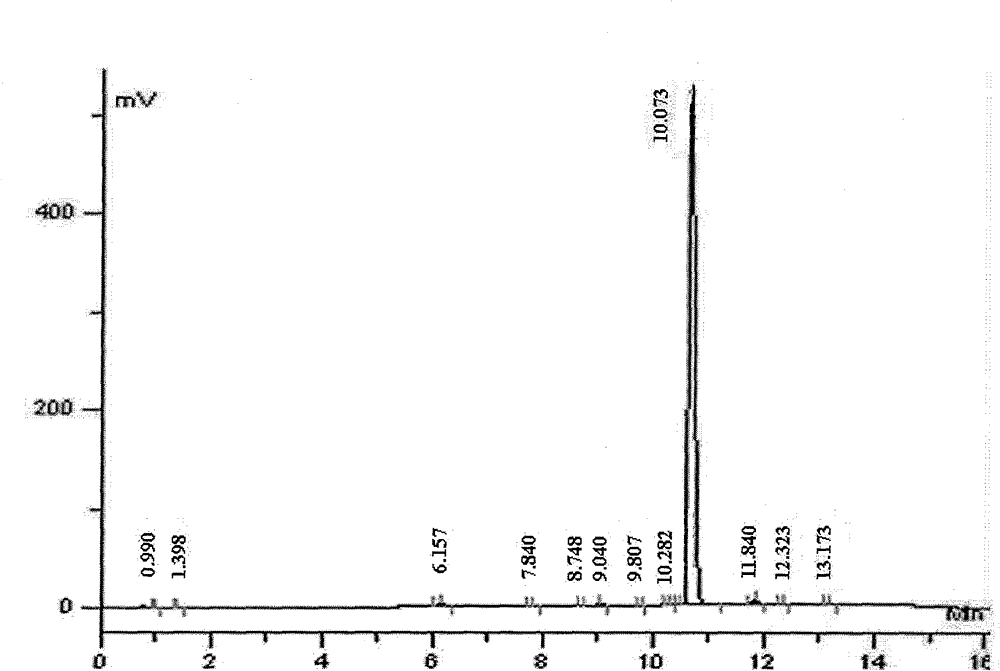

[0024]Example 1: Add 328g of TXP into the reactor, slowly add 44g of resorcinol, raise the temperature to 80°C, add 4g of sodium diphenylborate catalyst, raise the temperature to about 100°C, start stirring, and turn on the vacuum, the extracted 2,6 —Xylenol is recovered by the condenser, the reaction temperature is slowly raised to 250°C, and the reaction is kept for 3 hours. Cool to 100°C, add 300g of ethanol solution, continue cooling to below 50°C, the product begins to recrystallize, the precipitate is filtered and washed with deionized water, and the precipitate is dried at 60°C to obtain 233g of white powder which is resorcinol Bis[bis(2,6-dimethyl)phenyl phosphate]XDP, yield: 85%, melting point: 103°C, main content: 98.1%. The liquid chromatogram is shown in the accompanying drawing, and the data of each product peak are shown in Table 1.

Embodiment 2

[0025] Example 2: Add 328g of TXP into the reactor, slowly put in 44g of hydroquinone, raise the temperature to 80°C, add 4g of sodium diphenylborate, repeat the above process, and obtain 240g of white powder which is hydroquinone bis[bis(2, 6-Dimethyl)phenyl phosphate], the yield is 87.6%, the melting point is 105°C, and the main content is 97.7%.

Embodiment 3

[0026] Example 3: Add 260g of TPP (triphenyl phosphate) into the reactor, slowly add 44g of resorcinol, repeat the above reaction process, add 60g of deionized water after the reaction is completed, stir at 70°C for one hour, separate layers, and The remaining water was removed by vacuum distillation in the oil layer to obtain 188g RDP with a yield of 81.7% and a main content of 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com