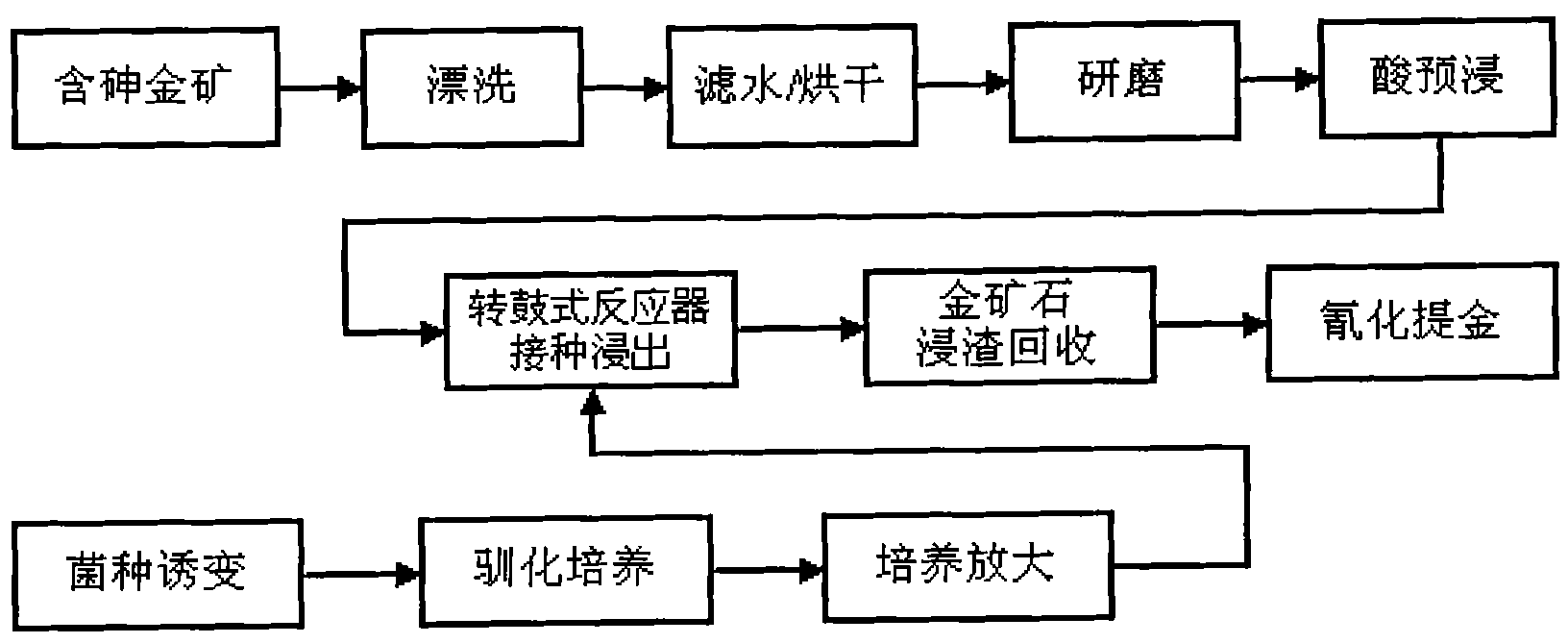

Preoxidation treating method for leaching arsenic golden ores by using drum type reactor organisms

A pre-oxidation treatment and bioleaching technology, applied in the direction of improving process efficiency, can solve the problems of harsh pulp concentration, pH and temperature control conditions, unsatisfactory oxidation effect, high mass transfer and low shear, etc., to achieve dissolved oxygen supply. Fully, improve the leaching effect, the effect of uniform gas-liquid distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

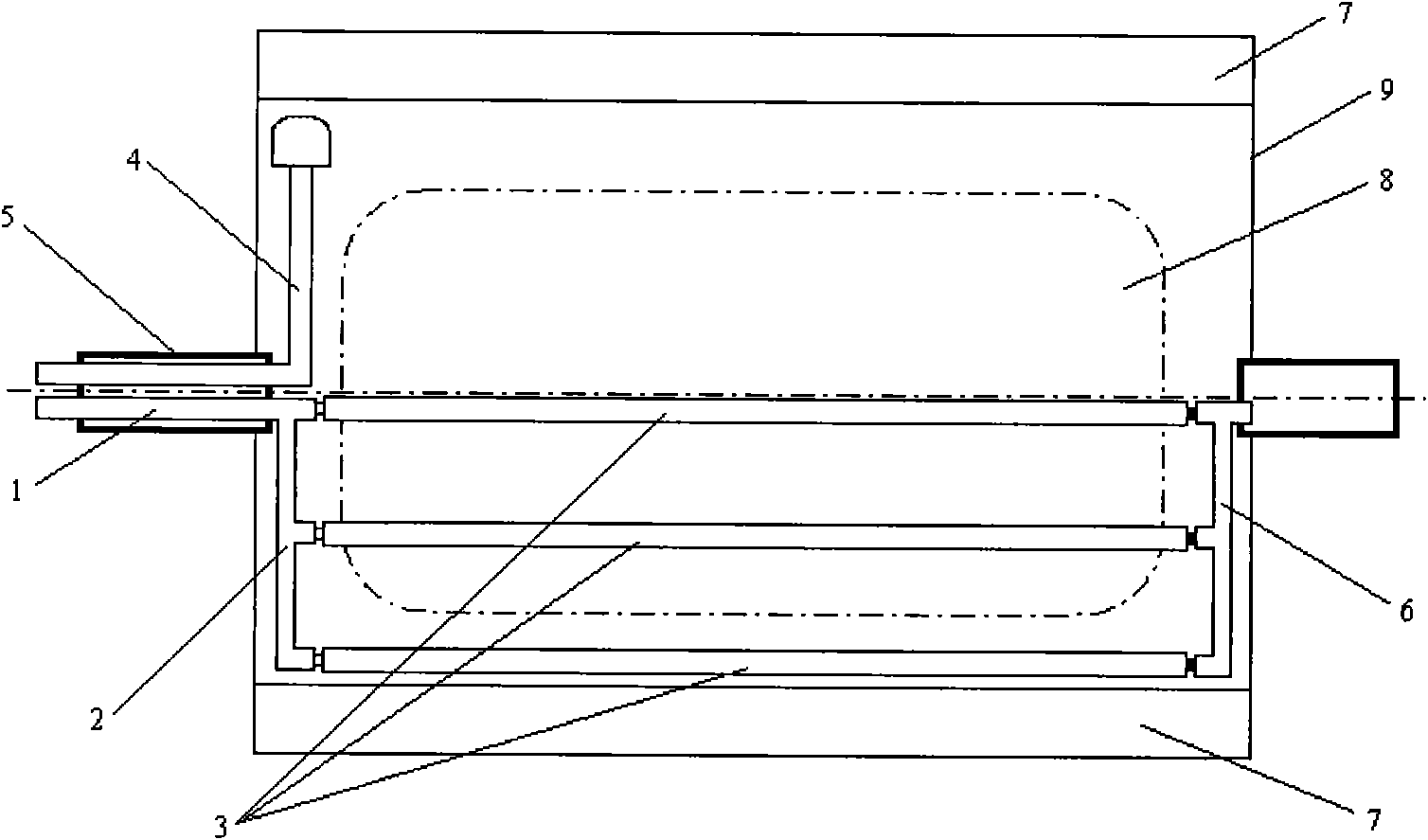

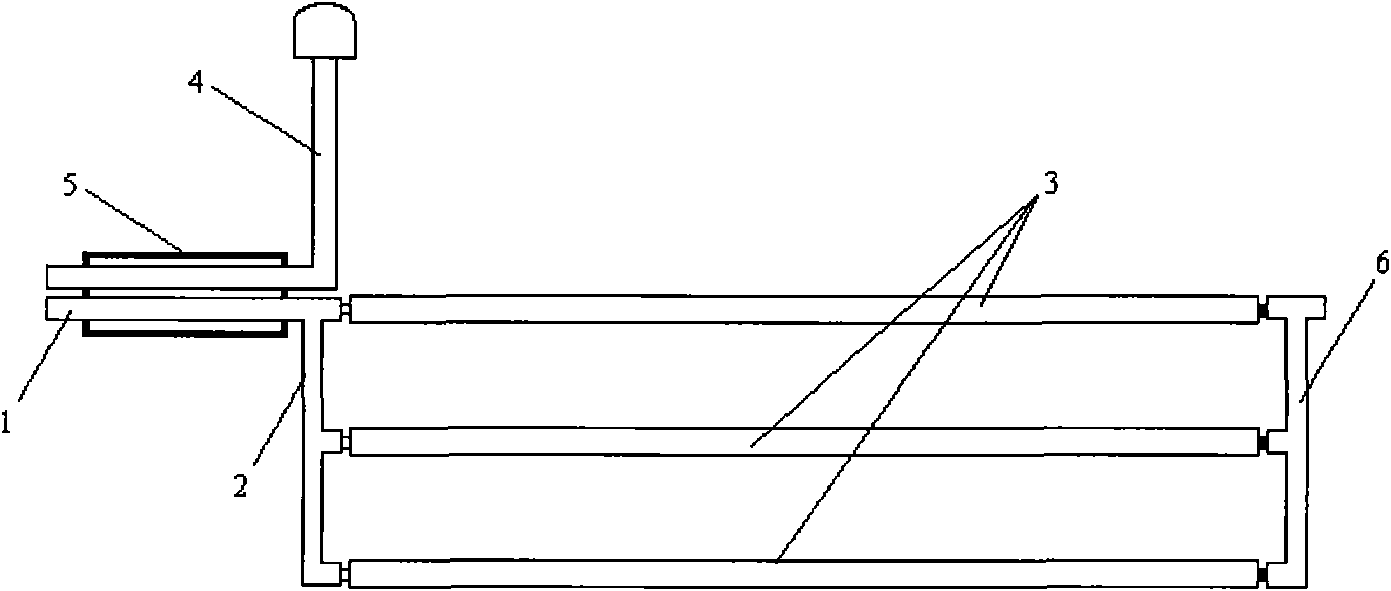

[0038] Example 1 Using a drum reactor to bioleach simulated systems with different pulp concentrations

[0039] Use alumina inert particles to simulate minerals, and change the particle concentration (particle collision frequency) in the reactor by adding different amounts of alumina particles in the drum bioreactor to induce mixed bacteria to oxidize Fe 2+ The process represents the effect of different particle concentrations on the oxidation activity of leaching microorganisms. During the controlled leaching process, the rotational speed of the drum bioreactor was 3.33r / min, and the ventilation rate was 6L / min. The inoculation amount is 3% of the liquid volume, and the reaction temperature is 30°C. At various solid particle concentrations, Fe in the drum bioreactor 2+ The oxidation process showed the same characteristics, that is, in the first 8h Fe 2+ The concentration did not decrease basically, and the effect of the lag period in the corresponding bacterial growth proc...

Embodiment 2

[0040] Embodiment 2 adopts the pre-oxidation treatment method of arsenic-containing gold ore bioleaching by drum reactor

[0041] The bioleaching experiment of arsenic-containing gold ore was carried out in a drum bioreactor to examine the performance of the drum reactor in the actual bioleaching process. Fe was not added to the seed solution 2+ And add ore sample as the energy source of microbial growth, the inoculum size is 10% of the liquid volume. Temperature, rotating speed and ventilation rate are with embodiment (1). Harmful substances released during bioleaching, such as arsenic oxidation products, may inhibit the activity of leaching microorganisms. In order to avoid the influence of the above factors, keep the mineral concentration consistent, and change the total solid particle concentration in the reactor by adding different concentrations of alumina particles. During the bioleaching process of arsenic-containing gold ore in a drum bioreactor, the total iron con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com