Pymetrozine water dispersing granule and preparation method thereof

A technology of pymetrozine and disperse granules, applied in botany equipment and methods, insecticides, biocides, etc., can solve the problems of large filler consumption, environmental pollution, etc., to reduce negative impacts, reduce environmental pollution, flow good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: 10% pymetrozine water dispersible granules

[0022] Each component is (weight):

[0023] Pymetrozine 10 parts

[0024] 25 parts of polycarboxylate

[0025] Sodium Carboxymethyl Starch 12 parts

[0026] Sodium p-methoxy fatty acid amide benzene sulfonate 12 parts

[0027] Sodium carboxymethyl cellulose 10 parts

[0028] 31 parts of anhydrous sodium sulfate

[0029] Pymetrozine and other additives except the binder are crushed and mixed in a gravity-free mixer according to the formula ratio for 20 minutes, and then the mixture is put into a double screw mixer (Ⅰ), and the mixture is crushed by airflow while mixing It is crushed to a particle size of more than 1000 meshes, collected by a cyclone separator and a bag filter, and finally mixed with a double screw mixer (II) to obtain a uniform powder. Then accurately weigh a quantitative amount of powder in a boiling granulator, spray the binder according to the formula, and dry to obtain a granular water-dispersible granule ...

Embodiment 2

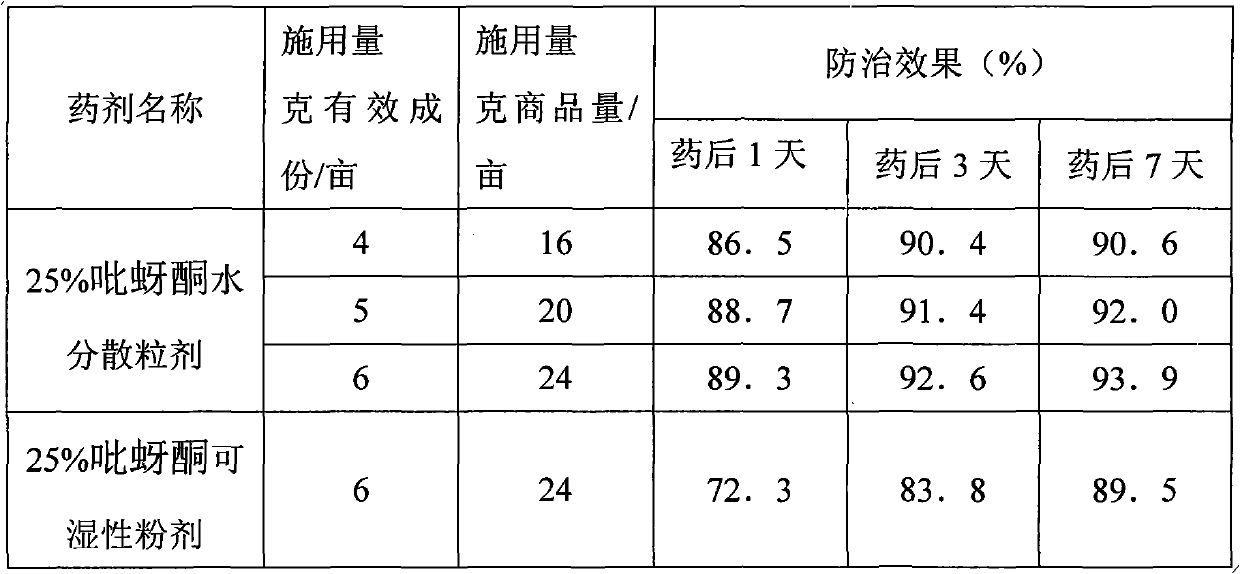

[0030] Example 2: 25% pymetrozine water dispersible granules

[0031] Pymetrozine 25 parts

[0032] 10 parts of polycarboxylate

[0033] Sodium Carboxymethyl Starch 5 parts

[0034] Sodium p-methoxy fatty acid amide benzene sulfonate 5 parts

[0035] Sodium carboxymethyl cellulose 1 part

[0036] 54 parts of anhydrous sodium sulfate

[0037] Prepare 25% pymetrozine water dispersible granules according to the method of Example 1.

Embodiment 3

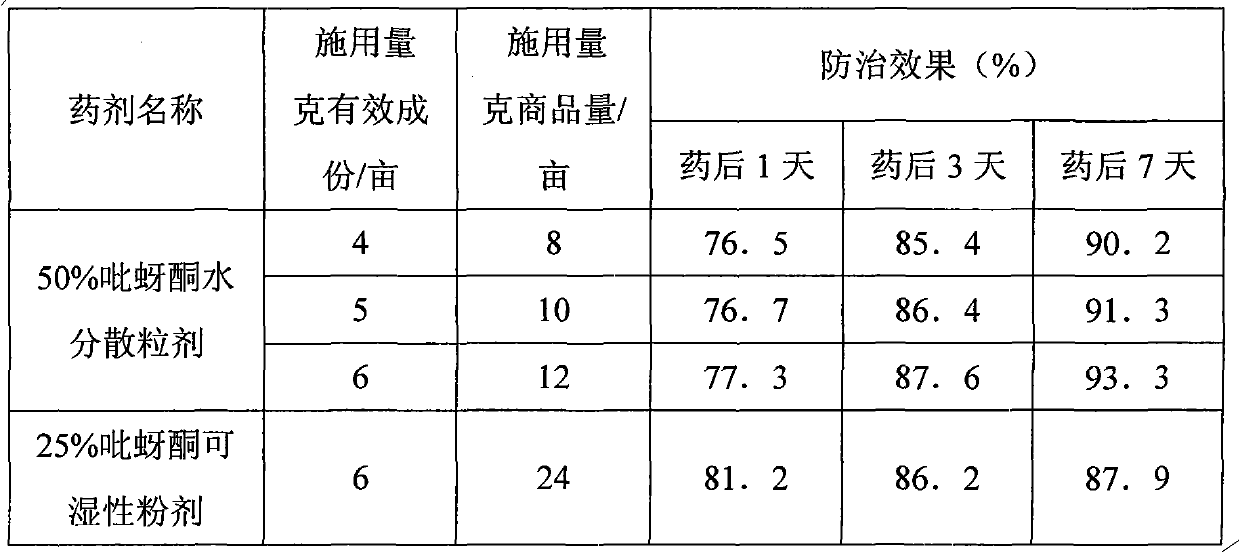

[0038] Example 3: 50% pymetrozine water dispersible granules

[0039] Pymetrozine 50 parts

[0040] 15 parts of polycarboxylate

[0041] Sodium Carboxymethyl Starch 10 parts

[0042] Sodium p-methoxy fatty acid amide benzene sulfonate 12 parts

[0043] 3 parts of sodium carboxymethyl cellulose

[0044] Anhydrous sodium sulfate 10 parts

[0045] According to the method of Example 1, 50% pymetrozine water dispersible granules were prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com