High-temperature slab imaging temperature detecting system in secondary cooling zone of continuous casting machine and temperature detecting method thereof

A technology of secondary cooling zone and continuous casting machine, applied in casting equipment, configuration of indicating equipment/measuring equipment, manufacturing tools, etc., can solve the problems of no process parameters, high equipment cost, damage measurement of temperature measuring components, etc. The effect of broad prospects, high measurement accuracy and fast dynamic response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings.

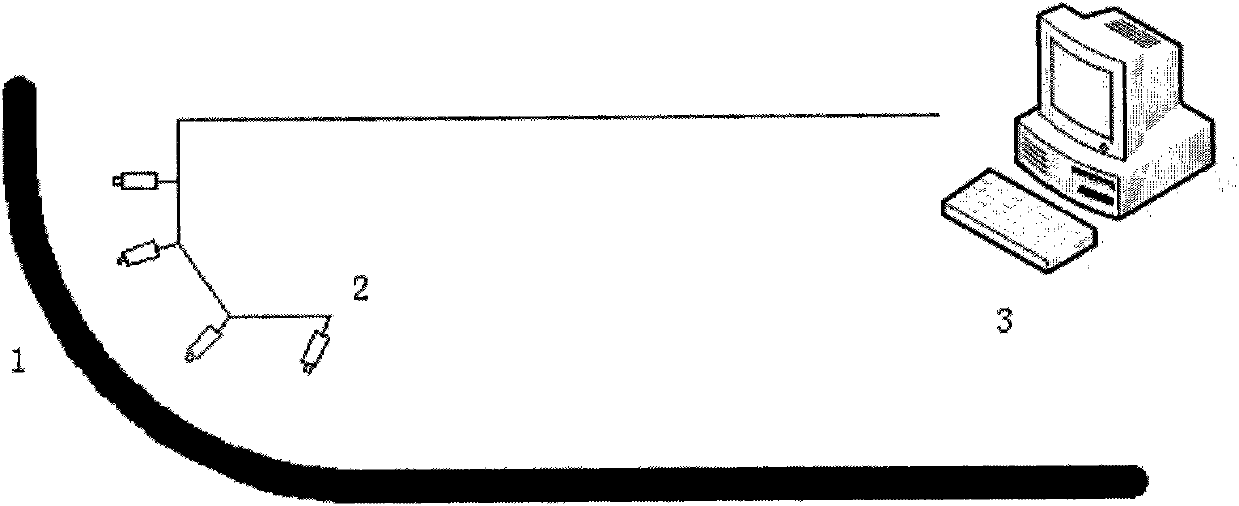

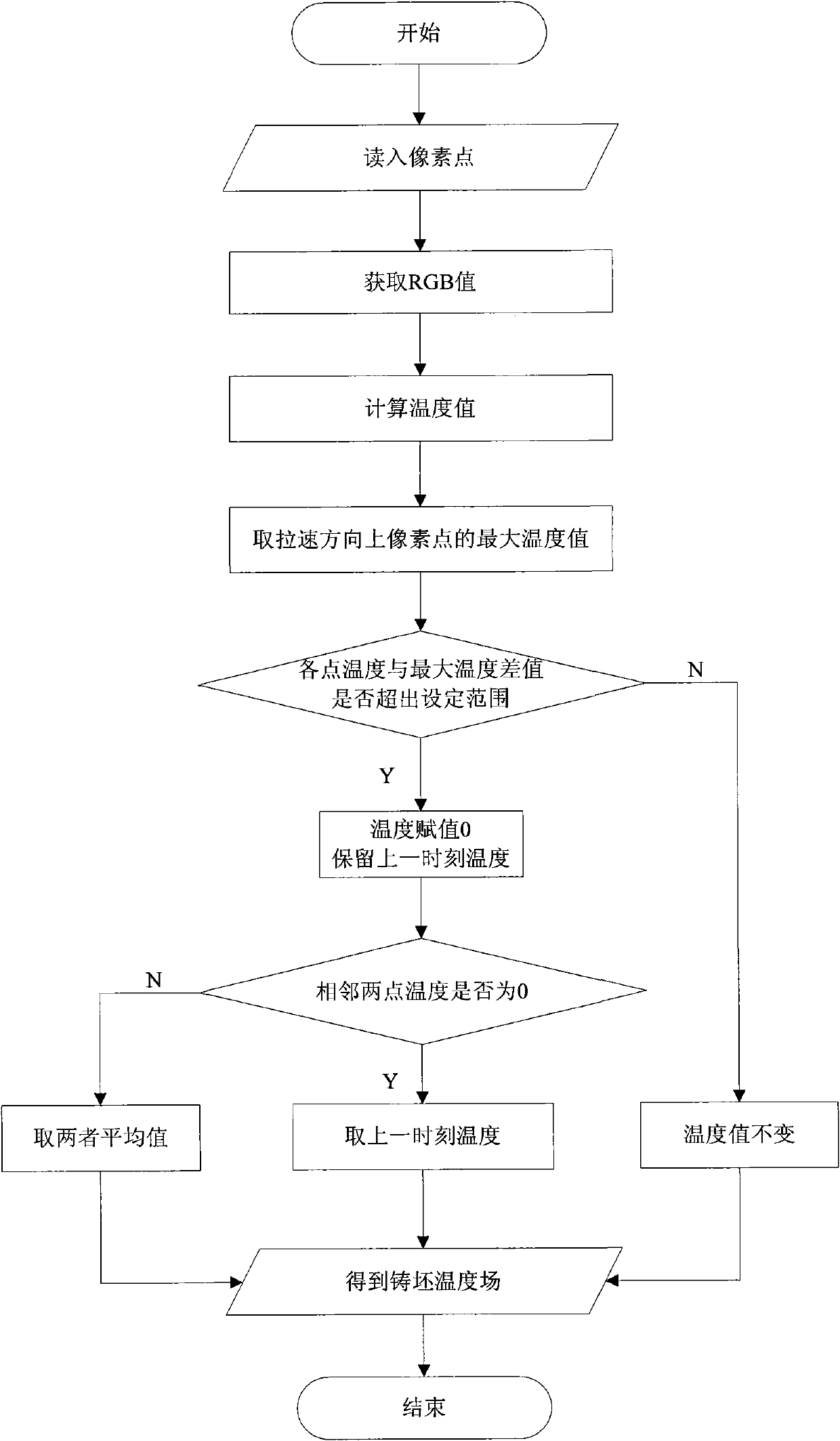

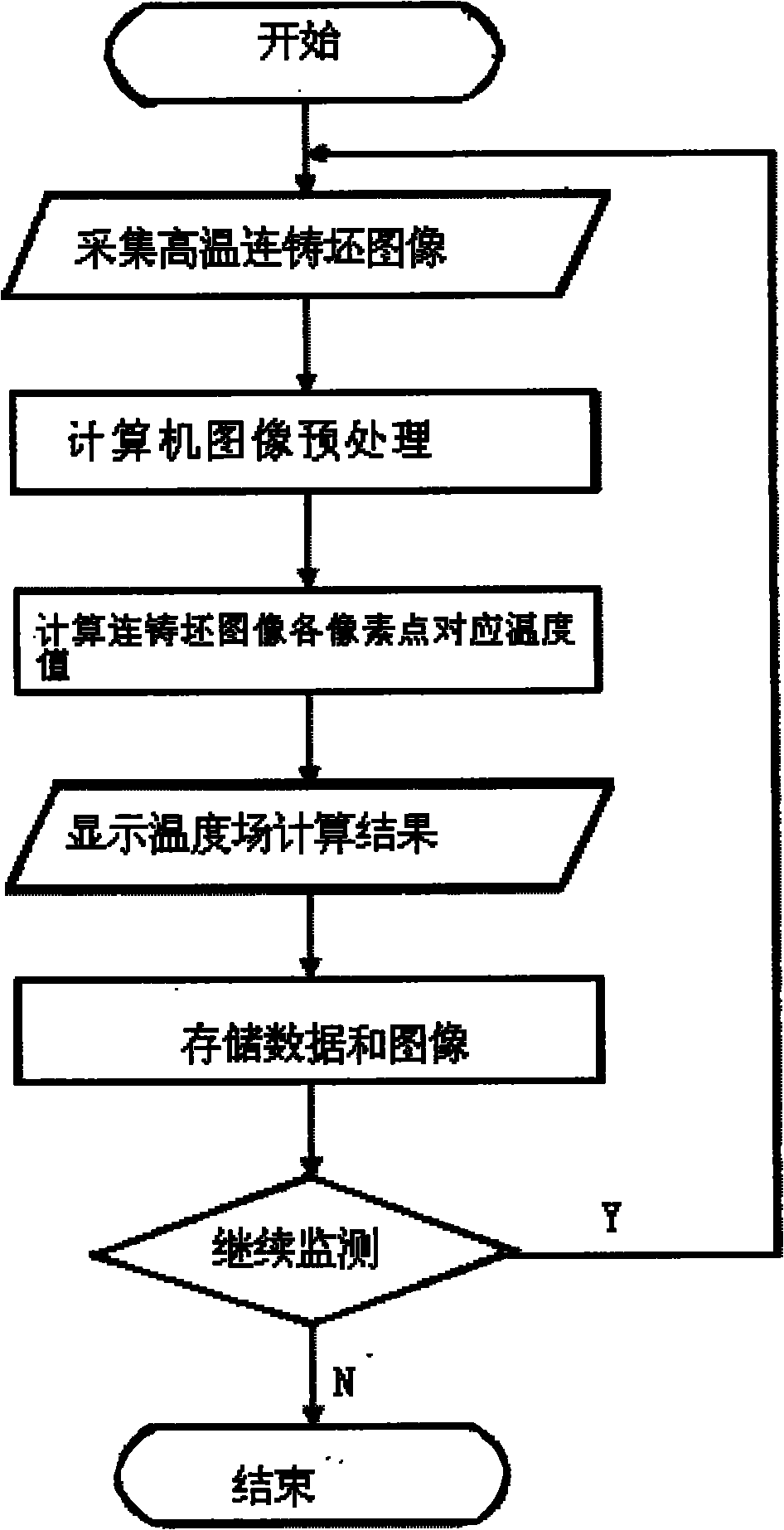

[0050] The application object of this embodiment is a certain flow casting slab of a certain bloom continuous casting machine, and the CCD camera image of the casting slab in the secondary cooling spray area is shown in Figure 1a , see the CCD camera image of the slab in the unsprayed area Figure 1b . refer to figure 2 , Weld the fixing frame at the appropriate position above the secondary cooling zone on the inner arc side of the 1 continuous casting machine, and install four 2-color area array CCD cameras on the designated positions, respectively: the images collected by each camera are transmitted to one through the image acquisition card 3 industrial control computers. The cameras all adopt wide-angle lenses and are installed at a distance of 3-5m from the high-temperature continuous casting slab, so as to obtain a complete image of the slab without being bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com