Method for making photoelectric hydrogen production electrode and photoelectric hydrogen production electrode

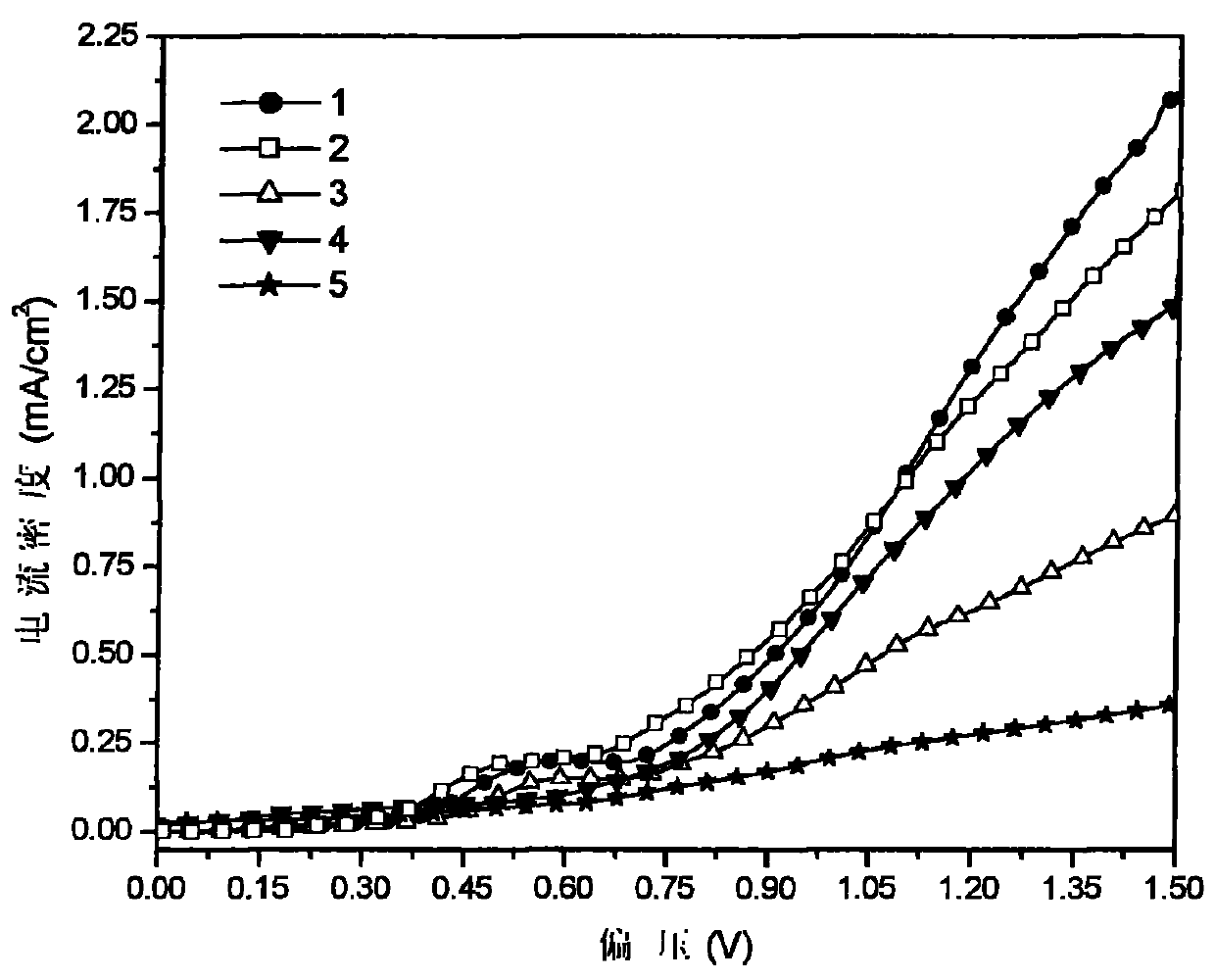

A photoelectric hydrogen production and electrode technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of high resistance, poor crystallinity, and poor conductivity of conductive glass, and achieve improved photoresponse current, good electrode stability, good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In the method for preparing the photoelectric hydrogen production electrode of the present invention provided by the present invention, the method includes the following steps: the first step, providing an anodized substrate; the second step, preparing a slurry for forming an oxide nanoporous film , wherein the oxide contained in the slurry is the oxide of the precursor metal of the anodized substrate; the third step is to apply the slurry to the anodized substrate so that the slurry is on the anodized substrate forming a film on the anodized substrate; and, in the fourth step, sintering the anodized substrate on which the film has been formed.

[0045] First, an anodized substrate suitable for use as a substrate for photoelectric hydrogen production electrodes is selected as the substrate. The precursor of the anodized substrate may be a metal selected from W, Ti, Fe, Ta, Zr and the like. Ta, Fe, Ti, and W are preferred, Fe, Ti, and W are more preferred, and W is part...

Embodiment 1

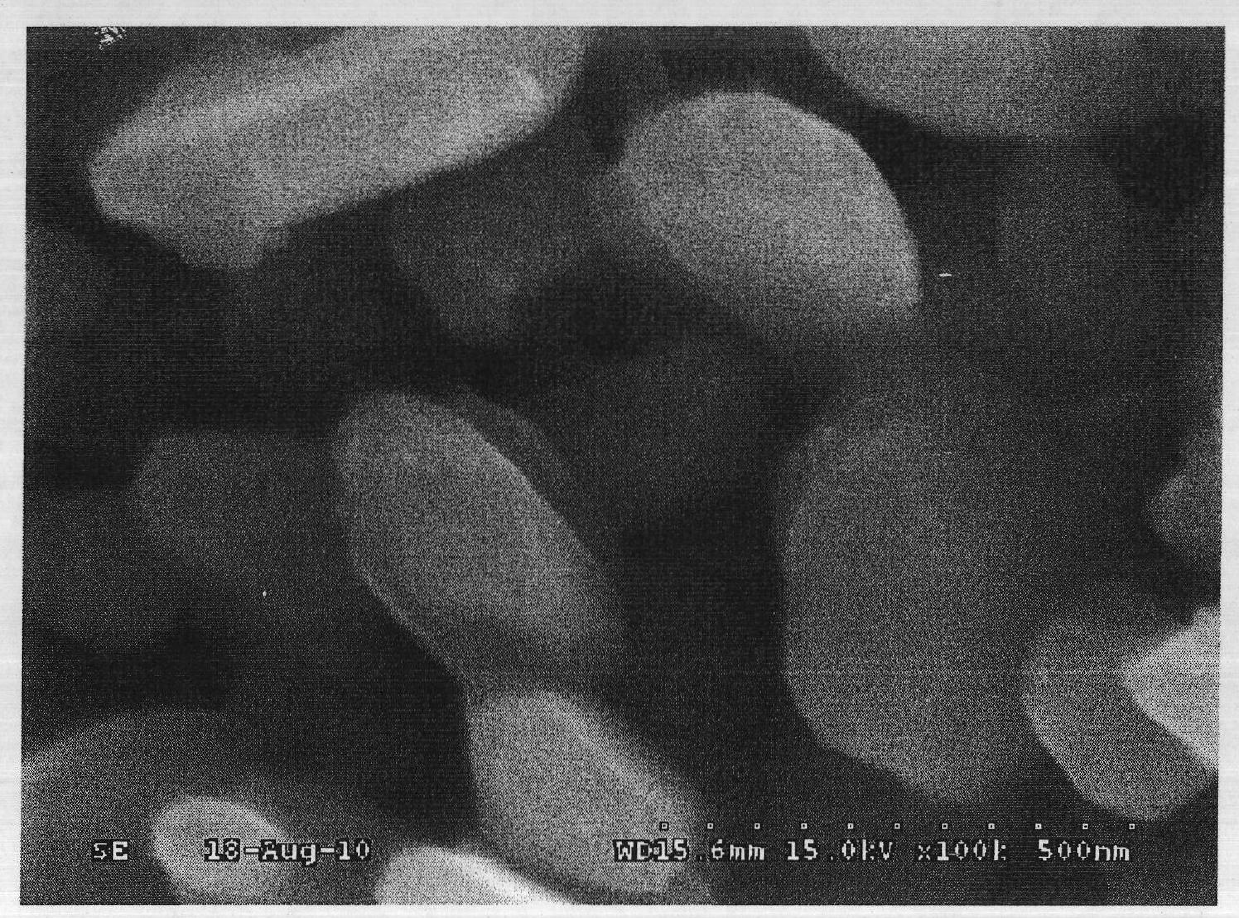

[0075] Example 1 Anodized substrate-WO 3 Preparation of nanoporous electrodes

[0076] 1. Preparation of anodized substrate

[0077] (1) Use 10mm×30mm×0.2mm metal tungsten sheet with a purity of 99.9% (provided by Beijing General Research Institute for Nonferrous Metals), and use 360-mesh, 600-mesh and 1000-mesh sandpaper to polish, and each kind of sandpaper to polish for 1min.

[0078] (2) Sonicate the polished tungsten sheet in ethanol for 30 minutes with an ultrasonic cleaner, and then dry it at 90°C.

[0079] (3) Place the cleaned two tungsten sheets in parallel in an anodic oxidation pool equipped with 2.0M nitric acid electrolyte, respectively as the anode and cathode of anodic oxidation, and the distance between the two is 2cm; The nitric acid electrolyte is heated to make its temperature reach 40°C; a constant voltage of 30V is applied between the cathode and the anode; the anodic oxidation time is 2 hours.

[0080] (4) Put the anodized tungsten sheet into a tube f...

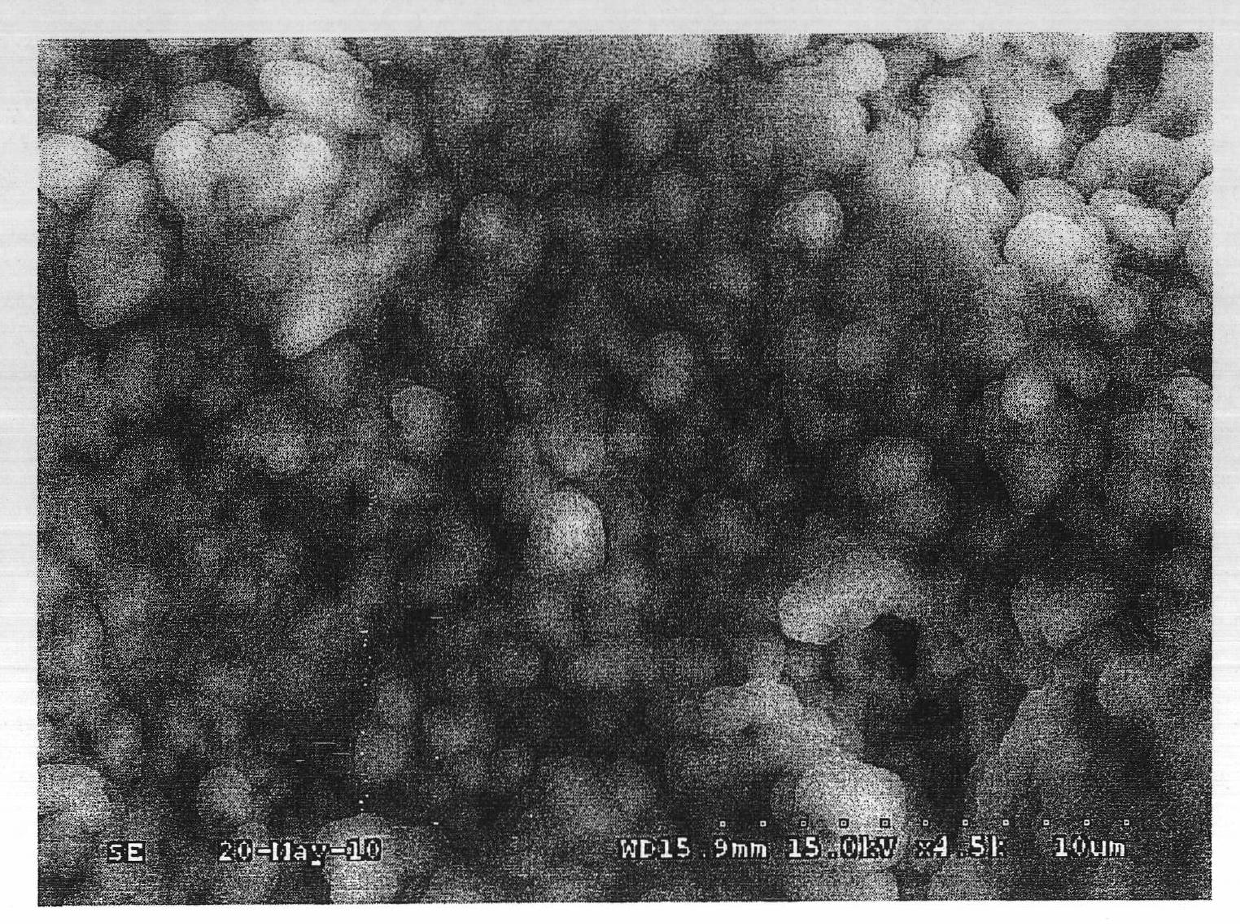

Embodiment 2

[0085] Example 2 Anodized substrate-WO 3 Preparation of nanoporous electrodes

[0086] 1. Preparation of anodized substrate

[0087] (1) Use 10mm×30mm×0.2mm metal tungsten sheet with a purity of 99.9% (Beijing General Research Institute for Nonferrous Metals), and polish it with 360 mesh, 600 mesh and 1000 mesh sandpaper, and polish each kind of sandpaper for 1 min.

[0088] (2) Sonicate the polished tungsten sheet in ethanol for 30 minutes with an ultrasonic cleaner, and then dry it at 90°C.

[0089] (3) Place the cleaned two tungsten sheets in parallel in an anodic oxidation pool equipped with 2.0M nitric acid electrolyte, respectively as the anode and cathode of anodic oxidation, and the distance between the two is 2cm; The nitric acid electrolyte is heated to 40°C; a constant voltage of 30V is applied between the cathode and the anode; the anodic oxidation time is 2 hours, and the anodized substrate is obtained.

[0090] 2. Add 1g WO 3 The nanopowder was mixed with 3g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com