Rapid dehydration dryer

A rapid dehydration, dehydration and drying technology, applied in the field of rapid dehydration dryer, sludge dehydration or drying treatment, stools, etc., can solve the problems of inconvenient treatment, slow processing time, difficult separation, etc., and achieve dehydration High efficiency, reasonable use of heat energy, and time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

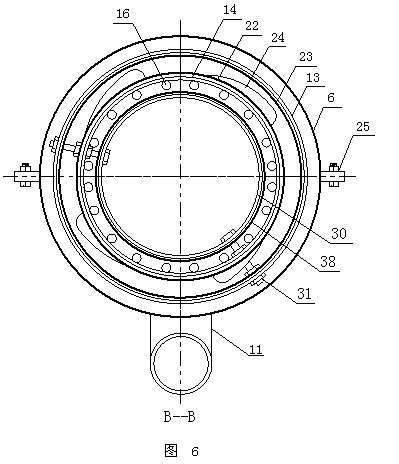

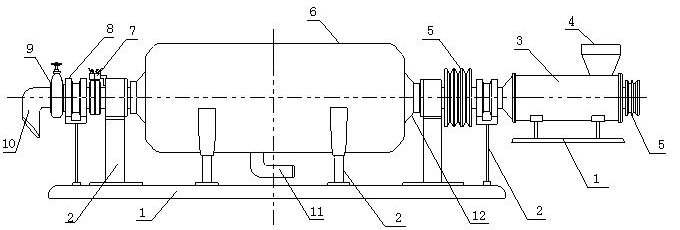

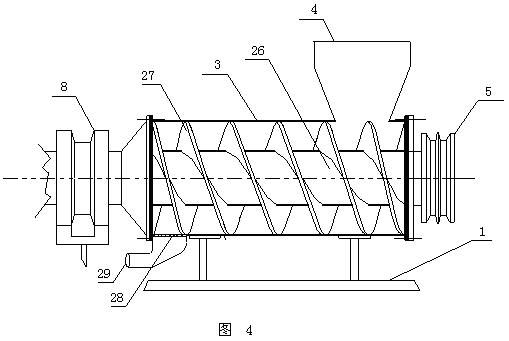

[0018] see figure 1 Among them, the structure diagram of the main body of the rapid dehydration dryer of the present invention is the main preferred option 1 of the present invention, which is characterized in that: a screw conveyor (3) is connected to a drum dehydration device for dehydration or drying treatment, and the material is conveyed by a screw Under the screw transport of the screw conveyor (3), the screw conveyor blade (27) at one end of the screw conveyor can be squeezed by the conical sleeve to squeeze the moisture of the material for the first time, and pass through the screen (28) and waste water The hole (29) discharges water, and the material is connected and transported to the drum dehydration device for dehydration or drying. In the process of processing, the outer drum (13) and inner drum (13) of the dehydration drum (12) 14) In the cavity, the material is conveyed while performing rapid spin dehydration. When the spin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com