Detergent composition for photoresists

A cleaning agent and composition technology, which is applied in the processing of photosensitive materials, etc., can solve the problems of strong corrosion of semiconductor wafer patterns and substrates, insufficient cleaning ability, etc., and achieve the effect of weak corrosion and reduced corrosion

Active Publication Date: 2010-12-08

ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

View PDF7 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0016] Therefore, the technical problem to be solved by the present invention is to provide a thick-film photoresist cleaning agent with insufficient cleaning ability or strong corrosion to semiconductor wafer patterns and substrates in existing thick-film photoresist cleaning agents. Photoresist cleaning agent composition with strong resist cleaning ability and low corrosion to semiconductor wafer patterns and substrates

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

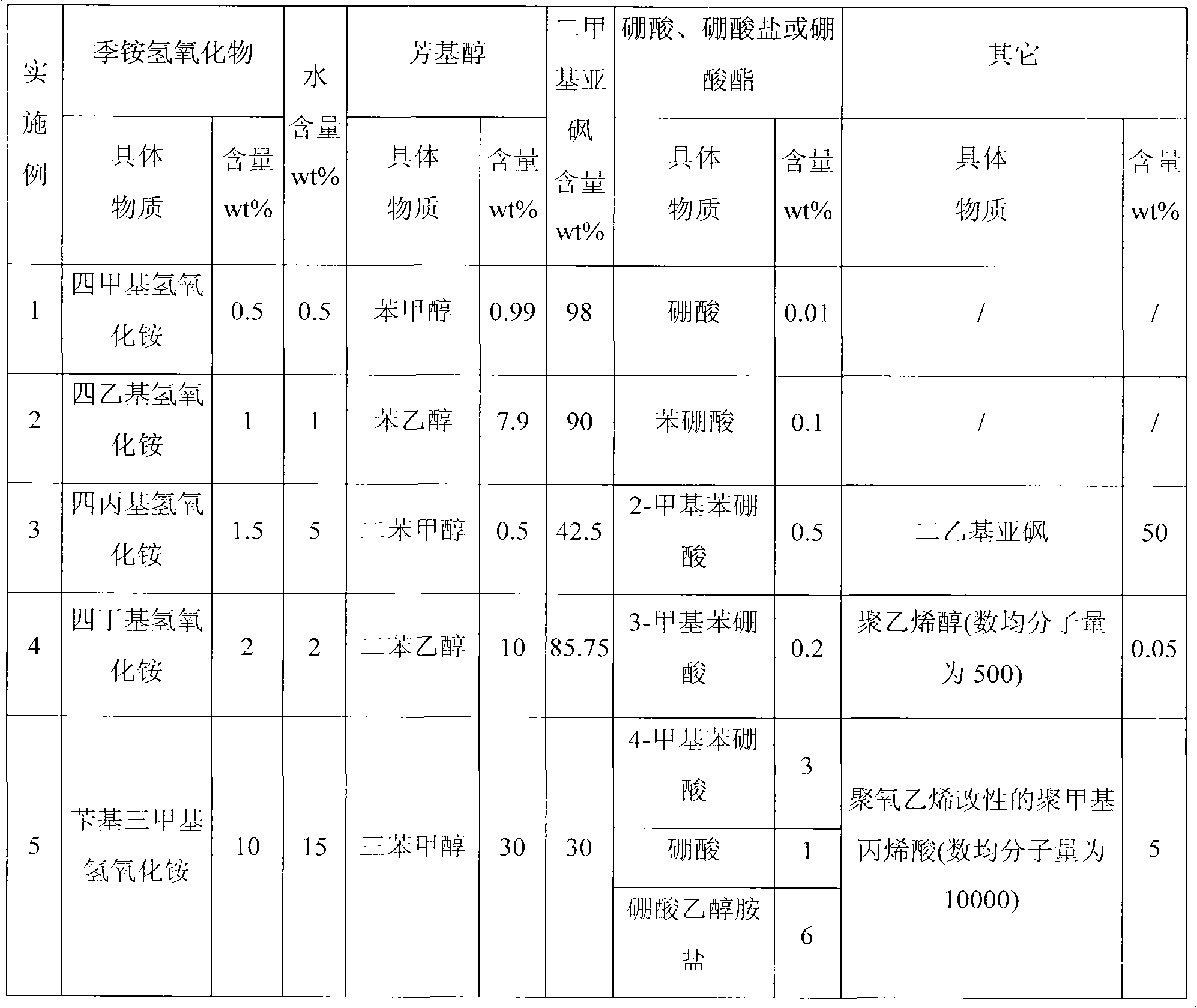

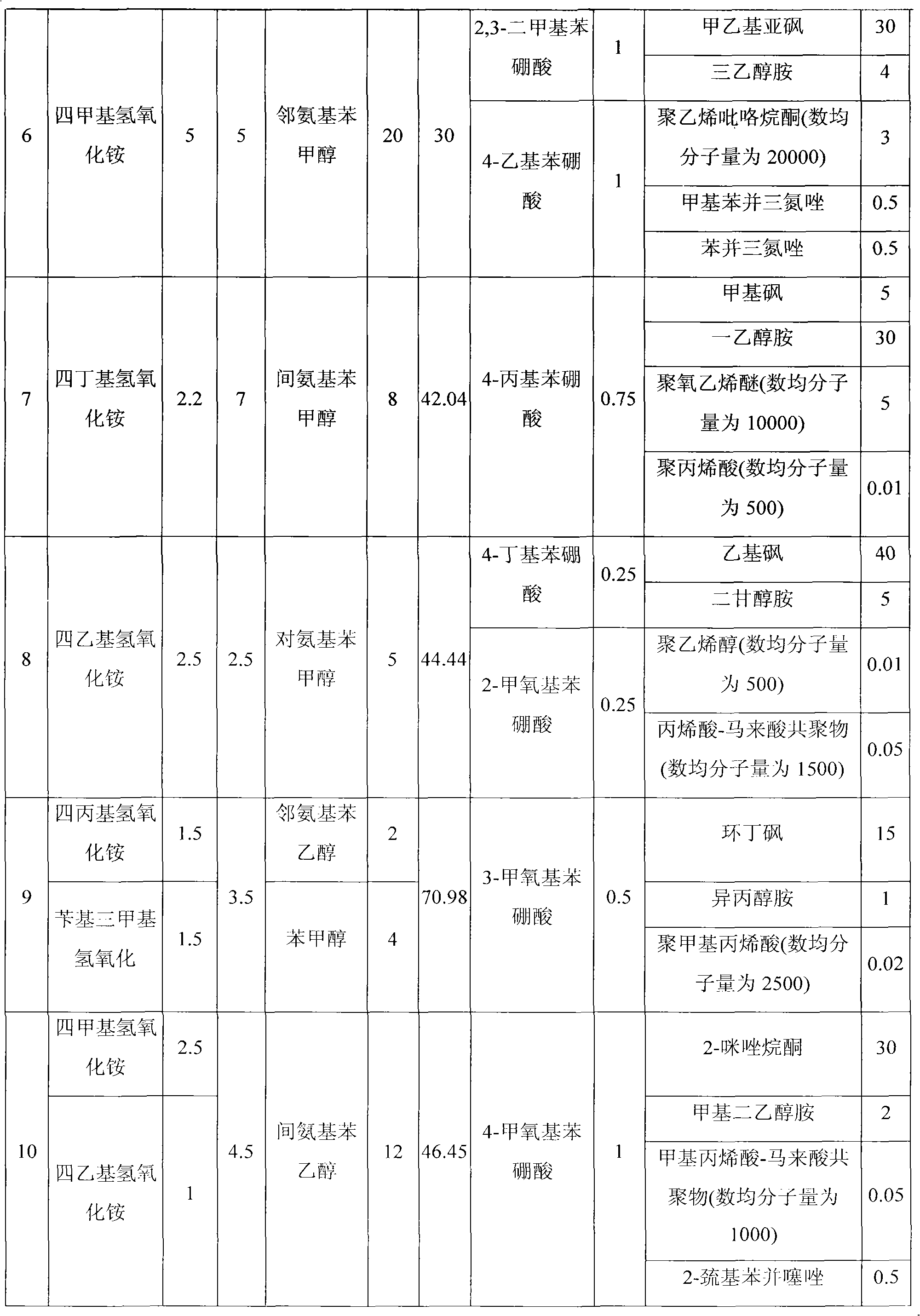

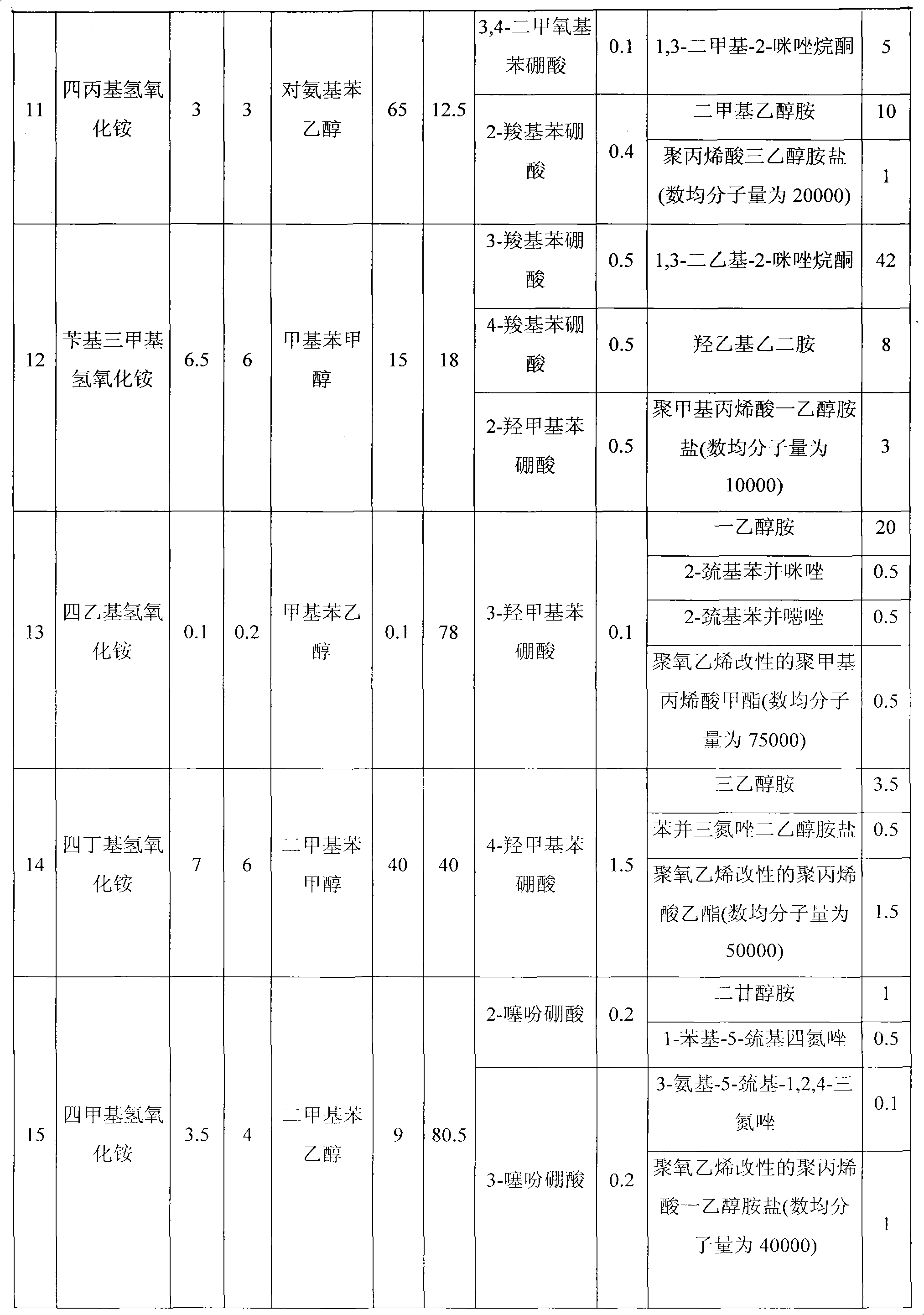

Embodiment 1~26

[0040]

[0041]

[0042]

[0043]

[0044]

[0045]

[0046] The beneficial effects of the present invention will be further illustrated below through effect examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a detergent composition for photoresists. The detergent composition for the photoresists comprises quaternary ammonium hydroxide, aryl alcohol, dimethyl sulfoxide, corrosion inhibitor and water, wherein the corrosion inhibitor contains one or more of boric acid, borate and boric acid ester. The detergent for the photoresists can remove the photoresists (particularly thick-film negative photoresists) with the thickness of more than 20 mu m and other etching residues on base materials such as metals, metal alloys, dielectrics and the like, and has lower corrosivity to metals such as aluminum, copper and the like and nonmetallic materials such as silicon dioxide and the like, so that the detergent composition for the photoresists has good application prospect in the fields of cleaning microelectronics such as semiconductor chips and the like.

Description

technical field [0001] The invention relates to a cleaning agent composition in a semiconductor manufacturing process, in particular to a photoresist cleaning agent composition. Background technique [0002] In the usual semiconductor manufacturing process, a photoresist coating is first formed on the surface of metals such as silicon dioxide, Cu (copper), and low-k materials, and then exposed and developed using an appropriate mask. According to the photoresist used To remove the exposed or unexposed part of the photoresist, form a photoresist pattern at the required position, and then perform plasma etching or reactive gas etching on the photoresist pattern to perform pattern transfer. Low temperature and fast cleaning process is an important direction for the development of semiconductor wafer manufacturing process. Negative photoresists with a thickness of more than 20 μm are gradually being used in the semiconductor wafer manufacturing process. At present, most photore...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G03F7/42

Inventor 彭洪修

Owner ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com