Preparation method of barium metaborate nano-powder

A nano-powder, barium metaborate technology, applied in borates, boron oxides, sustainable manufacturing/processing, etc., can solve the problems of inability to convert raw materials into products, complex process flow, harsh reaction conditions, etc. The effect of easy operation, simple preparation process and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of barium metaborate nano powder, the steps are:

[0040] A. Weigh barium hydroxide and boric acid with a molar ratio of 1:2, mix them evenly at room temperature, grind until they change from solid to wet, then from wet to viscous, and then continue to grind for 1 hour;

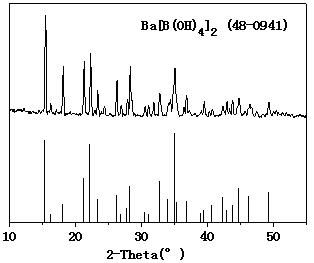

[0041] B, the product obtained in the last step is dried under air atmosphere and room temperature to obtain the product Ba[B(OH) 4 ] 2 , its X-ray diffraction pattern is as figure 1As shown, it is compared with the JCPDS standard card, showing that its crystal form is consistent with the JCPDS standard card 48-0941.

Embodiment 2

[0043] A preparation method of barium metaborate nano powder, the steps are:

[0044] A. Weigh barium hydroxide and boric acid with a molar ratio of 1:2, mix them evenly at room temperature, grind them until they change from solid to wet, then from wet to viscous, and then continue to grind for 1.5 hours ;

[0045] B. Put the product obtained in the previous step into a drying oven, and dry it in an air atmosphere at 40-60°C to obtain the product Ba[B(OH) 4 ] 2 , its X-ray diffraction pattern is as figure 1 As shown, it is compared with the JCPDS standard card, showing that its crystal form is consistent with the JCPDS standard card 48-0941.

Embodiment 3

[0047] A preparation method of barium metaborate nano powder, the steps are:

[0048] A. Weigh barium hydroxide and boric acid with a molar ratio of 1:2, mix them evenly at room temperature, grind until they change from solid to wet, then from wet to viscous, and then continue to grind for 1 hour;

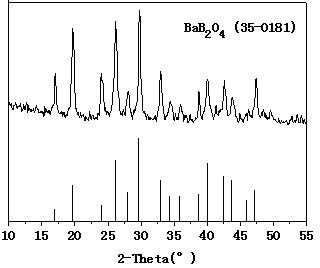

[0049] B. Put the product obtained in the previous step into a drying oven, and dry it in an air atmosphere at 100°C to obtain the product BaB 2 o 4 , its X-ray diffraction pattern is as figure 2 As shown, it is compared with the JCPDS standard card, showing that its crystal form is consistent with the JCPDS standard card 35-0181.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com