Synthesis process of calcium formate

A synthesis process, calcium formate technology, applied in carboxylate preparation, organic chemistry, etc., can solve the problems of high energy consumption, high equipment requirements, complex calcium formate synthesis process, etc., and achieve low energy consumption and simple production process technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

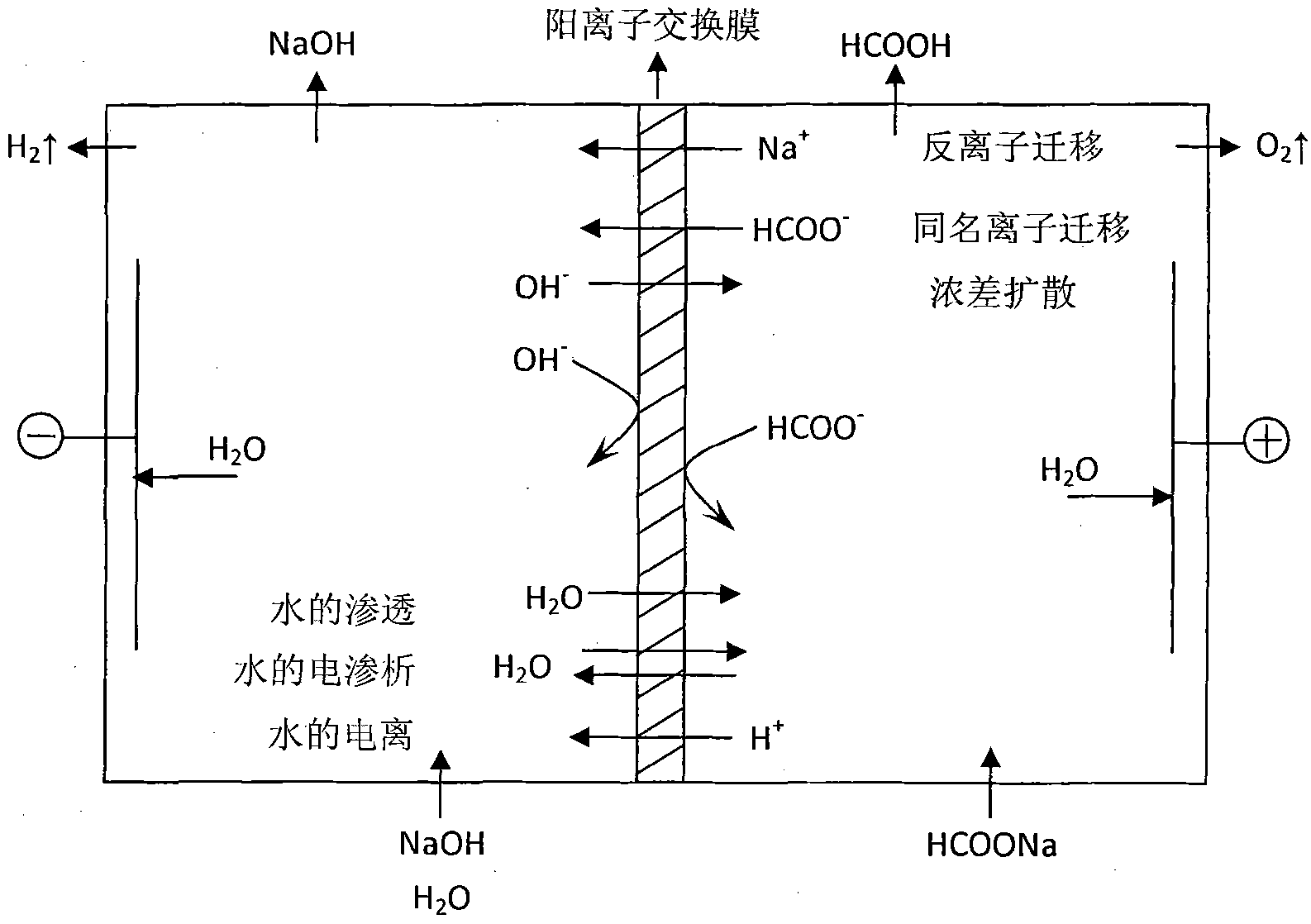

Method used

Image

Examples

Embodiment 1

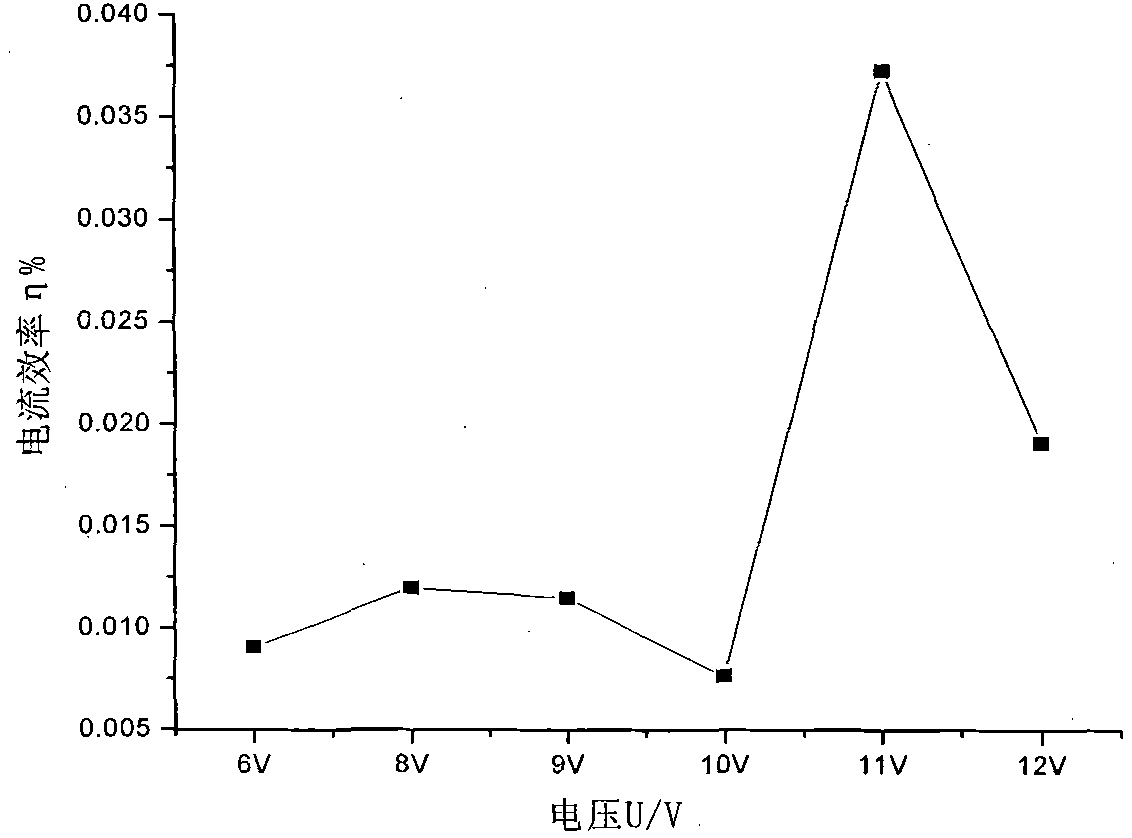

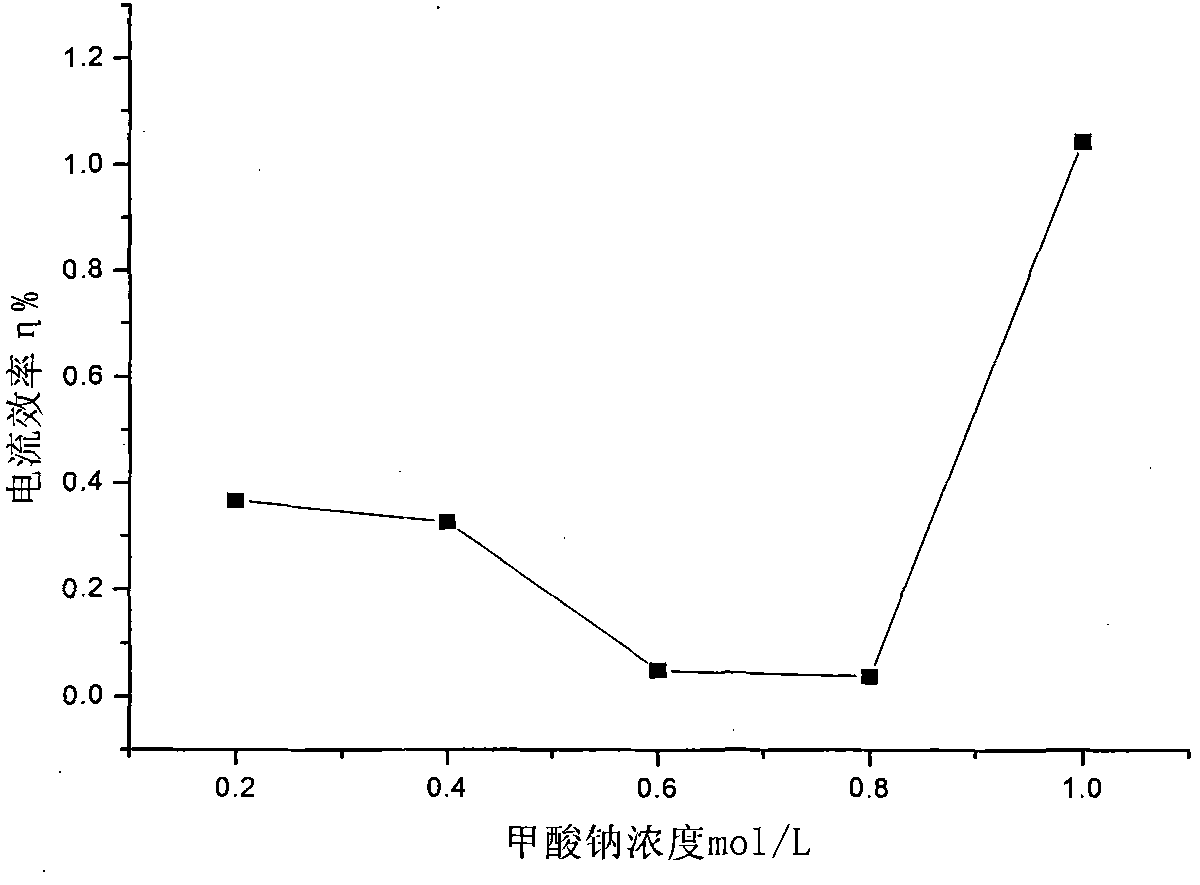

[0028] 1) Add the sodium formate solution of 0.2mol / L and the sodium hydroxide solution of 2mol / L respectively to the anode tank and the cathode tank of the cation exchange membrane electrodialyzer;

[0029] 2) The two ends of the anode plate and the cathode plate are connected to a DC power supply, the voltage is set to 5V, and the timing is started at the same time, and the current, voltage, and pH value of the solution in the cathode tank and the anode tank are recorded every 5 minutes;

[0030] 3) When the pH range is within ±0.1, discharge the solutions in the cathode tank and the anode tank, and add excess calcium carbonate powder to the anode tank solution to obtain a calcium formate solution.

Embodiment 2

[0032] 1) Add the sodium formate solution of 0.6mol / L and the sodium hydroxide solution of 0.01mol / L respectively to the anode tank and the cathode tank of the cation exchange membrane electrodialyzer;

[0033] 2) The two ends of the anode plate and the cathode plate are connected to a DC power supply, the voltage is set to 8V, and the timing is started at the same time, and the current, voltage, and pH value of the solution in the cathode tank and the anode tank are recorded every 5 minutes;

[0034] 3) When the pH range is within ±0.1, discharge the solutions in the cathode tank and the anode tank, and add excess calcium hydroxide powder to the anode tank solution to obtain a calcium formate solution.

Embodiment 3

[0036] 1) Add the sodium formate solution of 0.4mol / L and the sodium hydroxide solution of 0.05mol / L respectively to the anode tank and the cathode tank of the cation exchange membrane electrodialyzer;

[0037] 2) Connect the two ends of the anode plate and the cathode plate to a DC power supply, set the voltage to 9V, start timing at the same time, and record the current, voltage, and pH value of the solution in the cathode tank and the anode tank every 5 minutes;

[0038] 3) When the pH range is within ±0.1, discharge the solutions in the cathode tank and the anode tank, and add excess calcium carbonate powder to the anode tank solution to obtain a calcium formate solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com