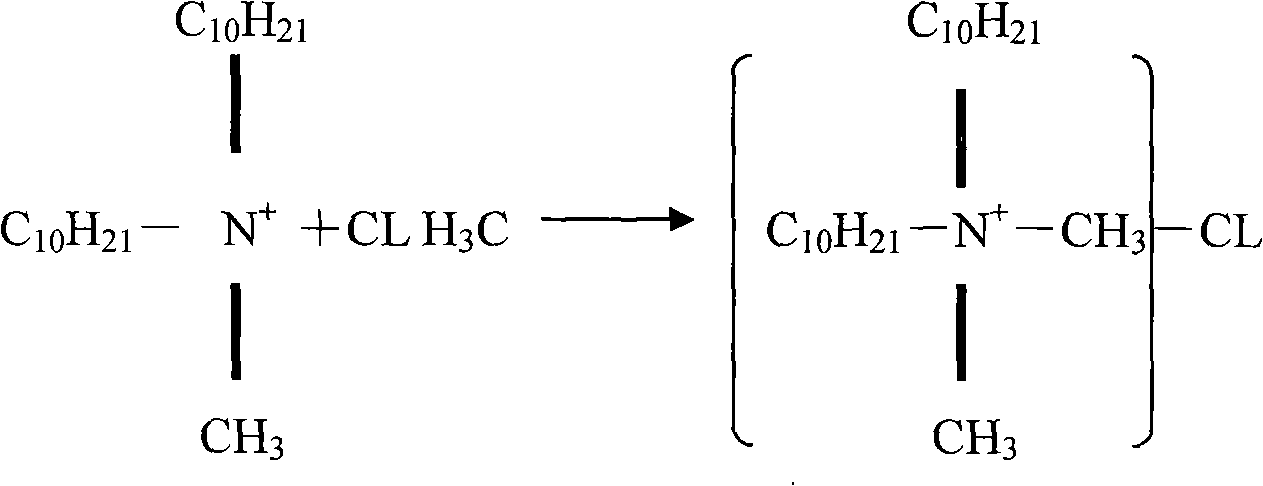

Process for preparing didecyl dimethyl ammonium chloride

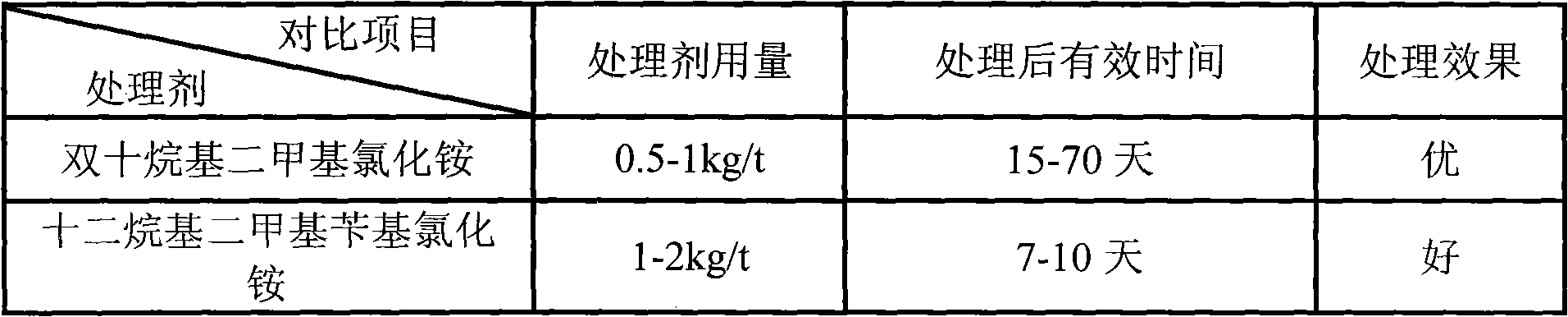

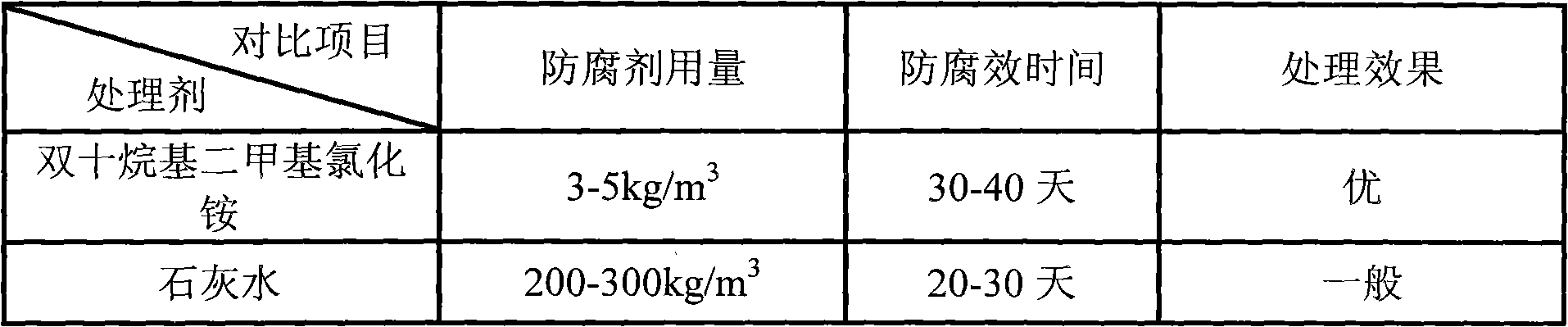

A didecyl dimethyl ammonium chloride, production process technology, applied in the field of preparation of didecyl dimethyl ammonium chloride, can solve the problem of limited production of didecyl dimethyl ammonium chloride, etc. problem, to achieve superior effect, simple process conditions and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Add 4.11mol of didecylmethyl tertiary amine into the reaction kettle, inhale 0.047mol of alkaline catalyst sodium carbonate, add 8.04mol of ethanol and stir; when heated to 75°C-95°C, open the methyl chloride addition valve to add The dosage is 4.21mol, and the condensing reflux system is turned on for condensing reflux. The addition temperature is between 75°C and 90°C. If the temperature rises, cooling water must be turned on to cool and lower the temperature. The pressure during the reaction shall not exceed 0.18MPa , react for 4.5 hours, after the reaction is completed, keep warm for 2.5 hours at 80°C to 90°C, then cool down and empty, and discharge the finished product for packaging. The analysis indicators are as follows:

[0016] Appearance: colorless transparent liquid

[0017] Content: 80.0%

[0018] PH value: 4.5

[0019] Free amine: 0.05%

[0020] Conformity.

Embodiment 2

[0022] Add 4.21mol of didecylmethyl tertiary amine into the reaction kettle, inhale 0.0475mol of alkaline catalyst sodium carbonate, add 8.14mol of ethanol and stir; when heated to 75℃~95℃, open the methyl chloride addition valve to add The dosage is 4.31mol, and the condensing and reflux system is turned on for condensing and reflux. The addition temperature is between 75°C and 90°C. If the temperature rises, cooling water must be turned on to cool and lower the temperature. The pressure during the reaction shall not exceed 0.18MPa , react for 5 hours, after the reaction is completed, keep warm for 2.5 hours at 80°C to 90°C, then cool down and empty, and discharge the finished product for packaging. The analysis indicators are as follows: The product indicators for this analysis are:

[0023] Appearance: colorless transparent liquid

[0024] Content: 80.4%

[0025] PH value: 6.2

[0026] Free amine: 0.85%

[0027] Conformity.

Embodiment 3

[0029] Add 4.31mol of didecylmethyl tertiary amine into the reaction kettle, inhale 0.048mol of alkaline catalyst sodium carbonate, add 8.24mol of ethanol and stir; after heating to 75℃~95℃, open the methyl chloride addition valve to add The dosage is 4.41mol, and the condensing reflux system is turned on for condensing reflux. The addition temperature is between 75°C and 90°C. If the temperature rises, cooling water must be turned on to cool and lower the temperature. The pressure during the reaction shall not exceed 0.18MPa , react for 5 hours, after the reaction is completed, keep warm for 2.5 hours at 80°C to 90°C, then cool down and empty, and discharge the finished product for packaging. The analysis indicators are as follows:

[0030] Appearance: colorless transparent liquid

[0031] Content: 82.0%

[0032] PH value: 7.5

[0033] Free amine: 0.98%

[0034] Conformity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com