Method for preparing polymer composite material with fluorescent property

A technology of composite materials and fluorescent properties, which is applied in the field of preparation of polymer composite materials, and can solve the problems of unreported polymer composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Preparation of basic zinc carbonate - solution reaction precipitation - hydrothermal treatment method:

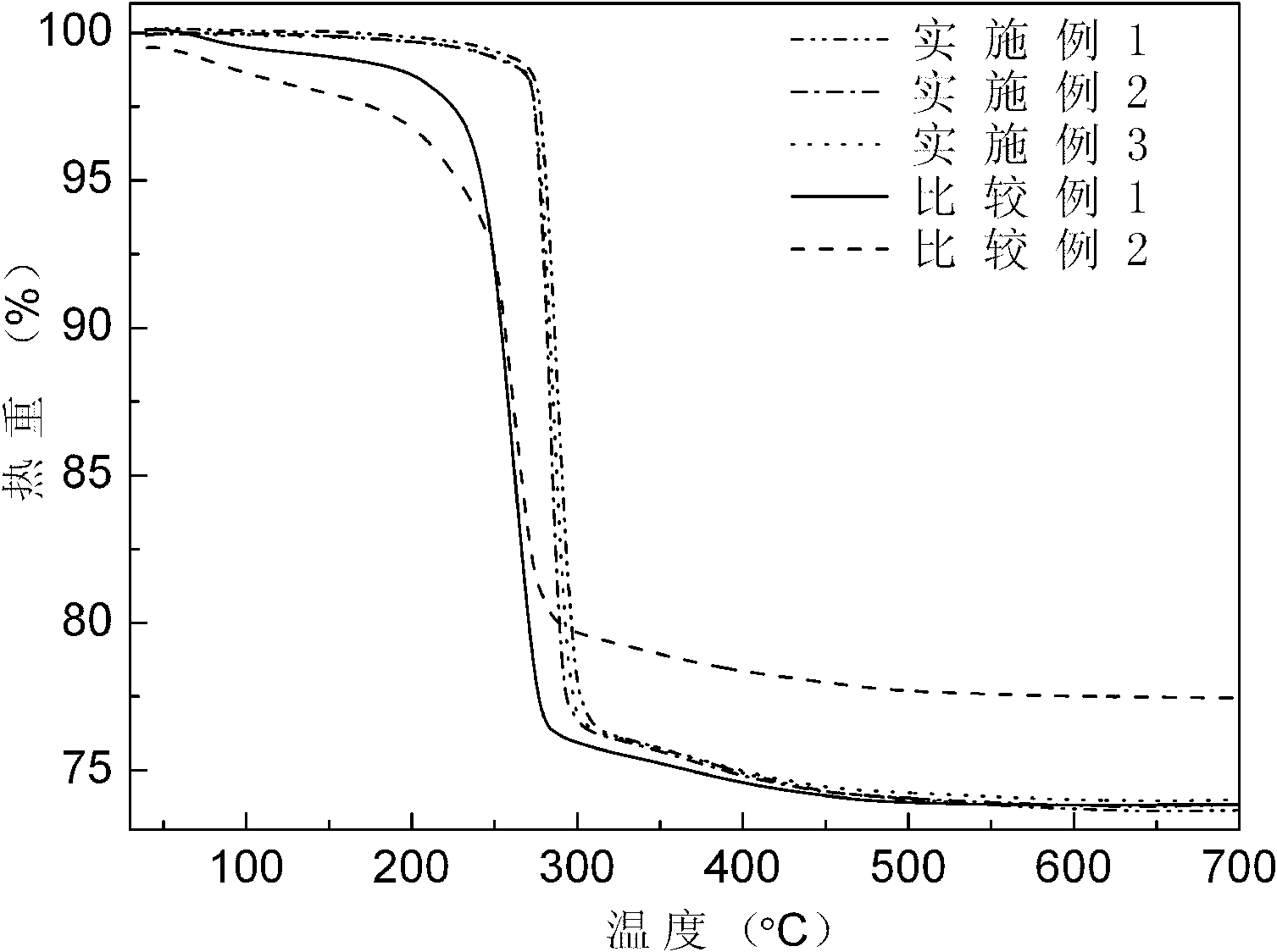

[0021] Add 52.40 parts of ammonium carbonate aqueous solution with a concentration of 0.5 mol / L to 57.44 parts of zinc nitrate aqueous solution with a concentration of 0.5 mol / L, suction filter the resulting precipitate and wash it with distilled water, add it to the autoclave, add 45 parts of distilled water, After heat preservation at 200°C for 20 hours, suction filtration, washing with distilled water, and drying to obtain basic zinc carbonate, the thermal weight loss curve is as follows: figure 1 It can be seen from the figure that basic zinc carbonate begins to decompose at about 270°C, which can be applied to higher processing temperatures.

[0022] (2) Preparation of a polymer composite material with fluorescent properties:

[0023] 100 parts of carboxylated hydrogenated nitrile rubber and 8 parts of basic zinc carbonate were blended on a two-roll mill, a...

Embodiment 2

[0025] (1) Preparation of basic zinc carbonate - solution reaction precipitation - hydrothermal treatment method:

[0026] Add 52.40 parts of ammonium carbonate aqueous solution with a concentration of 0.5 mol / L to 57.44 parts of zinc nitrate aqueous solution with a concentration of 0.5 mol / L, suction filter the resulting precipitate and wash it with distilled water, add it to the autoclave, add 45 parts of distilled water, After heat preservation at 200°C for 30 hours, suction filtration, washing with distilled water, and drying to obtain basic zinc carbonate, the thermal weight loss curve is as follows: figure 1 It can be seen from the figure that basic zinc carbonate begins to decompose at about 270°C, which can be applied to higher processing temperatures.

[0027] (2) Preparation of a polymer composite material with fluorescent properties:

[0028] 100 parts of carboxylated hydrogenated nitrile rubber and 8 parts of basic zinc carbonate were blended on a two-roll mill, a...

Embodiment 3

[0030] (1) Preparation of basic zinc carbonate - solution reaction precipitation - hydrothermal treatment method:

[0031] Add 52.40 parts of ammonium carbonate aqueous solution with a concentration of 0.5 mol / L to 57.44 parts of zinc nitrate aqueous solution with a concentration of 0.5 mol / L, suction filter the resulting precipitate and wash it with distilled water, add it to the autoclave, add 45 parts of distilled water, After heat preservation at 200°C for 40 hours, filter with suction, wash with distilled water, and dry to obtain basic zinc carbonate, which has a thermal weight loss curve such as figure 1 It can be seen from the figure that basic zinc carbonate begins to decompose at about 270°C, which can be applied to higher processing temperatures.

[0032] (2) Preparation of a polymer composite material with fluorescent properties:

[0033] 100 parts of carboxylated hydrogenated nitrile rubber and 8 parts of basic zinc carbonate were blended on a two-roll mill, and v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com