Multi-component copolyamide containing side group and preparation method and application thereof

A multi-component copolymerized aramid and side group technology, applied in the field of polyamide, can solve the problems of decreased mechanical properties, decreased fiber strength and modulus, and cannot improve the solubility of PPTA.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

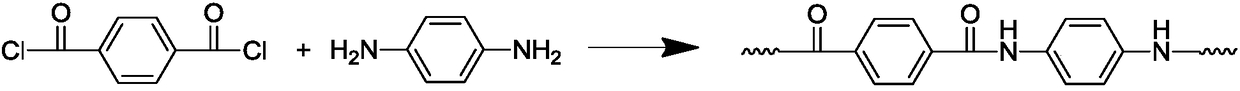

[0099] Embodiment 1 Synthetic formula (I) contains the multi-component copolymerized aromatic amide of triazine class side group

[0100] Prepared by low temperature polycondensation method.

[0101] Mix 0.3 mmol of terephthaloyl chloride, 1.0 mmol of p-phenylenediamine and 0.7 mmol of 2-(2,5-diformylchlorophenyl)-4,6-diphenyl-s-triazine in 5 mL of NMP-LiCl (LiCl The mass concentration is 4%), stirred in ice bath for 0.5 hours, then removed the ice bath, and continued to react at 15°C for 0.5 hours. The reaction solution was poured into 200 mL of methanol, and washed with 200 mL of 100° C. hot water to obtain a white precipitate.

[0102] The polymer was characterized by GPC, and a single peak was obtained, indicating that the polymerization was carried out very efficiently, with a number average molecular weight of 62,000 and a dispersion of 1.87. The polymer has very good solubility properties and can be dissolved in organic solvents such as NMP, DMSO, DMAc, NMP-LiCl or DM...

Embodiment 2

[0103] Embodiment 2 Synthetic formula (I) contains the multi-component copolymerized aromatic amide of triazine class side group

[0104] Prepared by low temperature polycondensation method.

[0105] Mix 0.5 mmol of terephthaloyl chloride, 1.0 mmol of p-phenylenediamine and 0.5 mmol of 2-(2,5-diformylchlorophenyl)-4,6-diphenyl-s-triazine in 5 mL of NMP-LiCl (LiCl The mass concentration is 4%), stirred in an ice bath for 0.5 hours, then removed the ice bath, and continued to react at 40° C. for 4 hours. The reaction solution was poured into 200 mL of methanol, and washed with 200 mL of 100° C. hot water to obtain a white precipitate.

[0106] The polymer was characterized by GPC, and a single peak was obtained, indicating that the polymerization was carried out very efficiently, with a number average molecular weight of 79,000 and a dispersion of 1.65. The polymer has very good solubility properties and can be dissolved in organic solvents such as NMP, DMSO, DMAc, NMP-LiCl or...

Embodiment 3

[0107] Embodiment 3 Synthetic formula (I) contains the multi-component polyarylamide of triazine class side group

[0108] Prepared by low temperature polycondensation method.

[0109] Mix 0.8 mmol of terephthaloyl chloride, 1.0 mmol of p-phenylenediamine and 0.2 mmol of 2-(2,5-diformylchlorophenyl)-4,6-diphenyl-s-triazine in 5 mL of NMP-LiCl (LiCl The mass concentration is 4%), stirred in ice bath for 0.5 hour, then removed the ice bath, and continued to react in 60°C oil bath for 48 hours. The reaction solution was poured into 200 mL of methanol, and washed with 200 mL of 100° C. hot water to obtain a flocculent white precipitate.

[0110] The polymer was characterized by GPC, and a single peak was obtained, indicating that the polymerization was carried out very efficiently, with a number average molecular weight of 81,000 and a dispersion of 1.77. The 5% thermal weight loss temperature of the polymer in nitrogen and air is very high, and it has very good thermal stabilit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com