Converter or electric furnace steel-making slagging agent and preparation process thereof

A technology of electric furnace steelmaking and slagging agent, which is applied in the direction of electric furnace, process efficiency improvement, furnace, etc., and can solve problems such as environmental pollution, prolonging slagging time, and steel slag returning to dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with embodiment.

[0019] The preparation process of converter and electric furnace steelmaking slagging agent described in this embodiment includes raw material preparation, mechanical processing, mixing, wetting processing, die-casting and aging reaction. The specific steps are as follows:

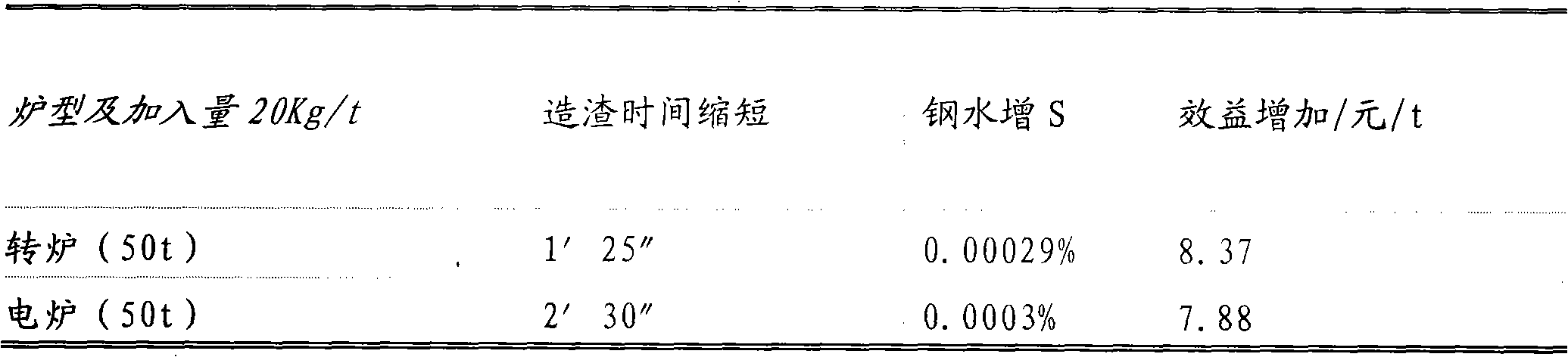

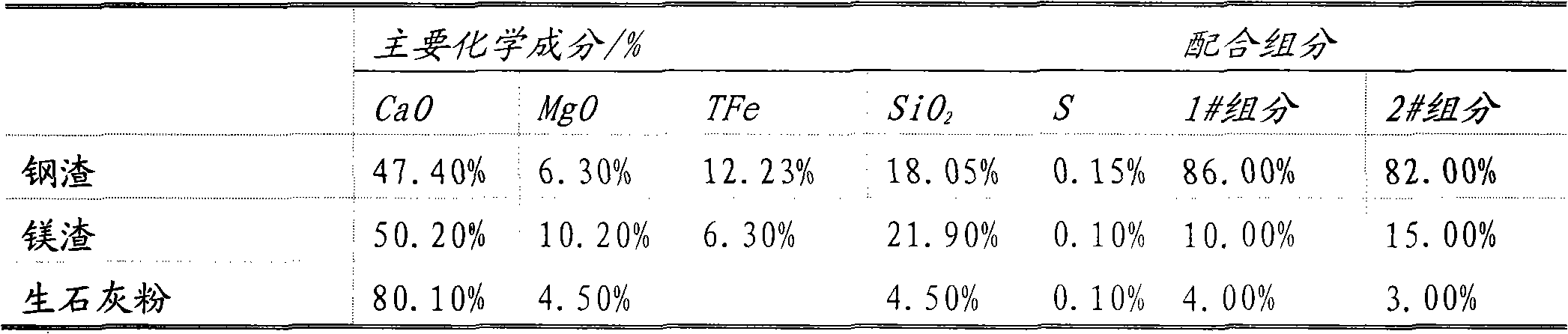

[0020] Raw material preparation: Table 1 provides two different raw material formulations for converter and electric furnace steelmaking slagging agents, and Table 2 provides the chemical composition of the two converter and electric furnace steelmaking slagging agents.

[0021] Mechanical processing is carried out according to the following procedures:

[0022] After the steel slag removes bricks and sundries → enters the jaw crusher → removes iron by the iron remover during belt conveyance → sends it to the roller mill and then removes iron → ball mill → process to the required specification (100-150 mesh) → Fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com