Polarized point diffraction interferometer system for test of low-reflectivity optical spherical surfaces

A point-diffraction interference and surface shape detection technology, which is applied in the direction of optical devices, measuring devices, instruments, etc., can solve problems such as the difficulty of adjusting the ratio of interference fringes, and achieve a simple and feasible detection method, simple structure, and easy assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

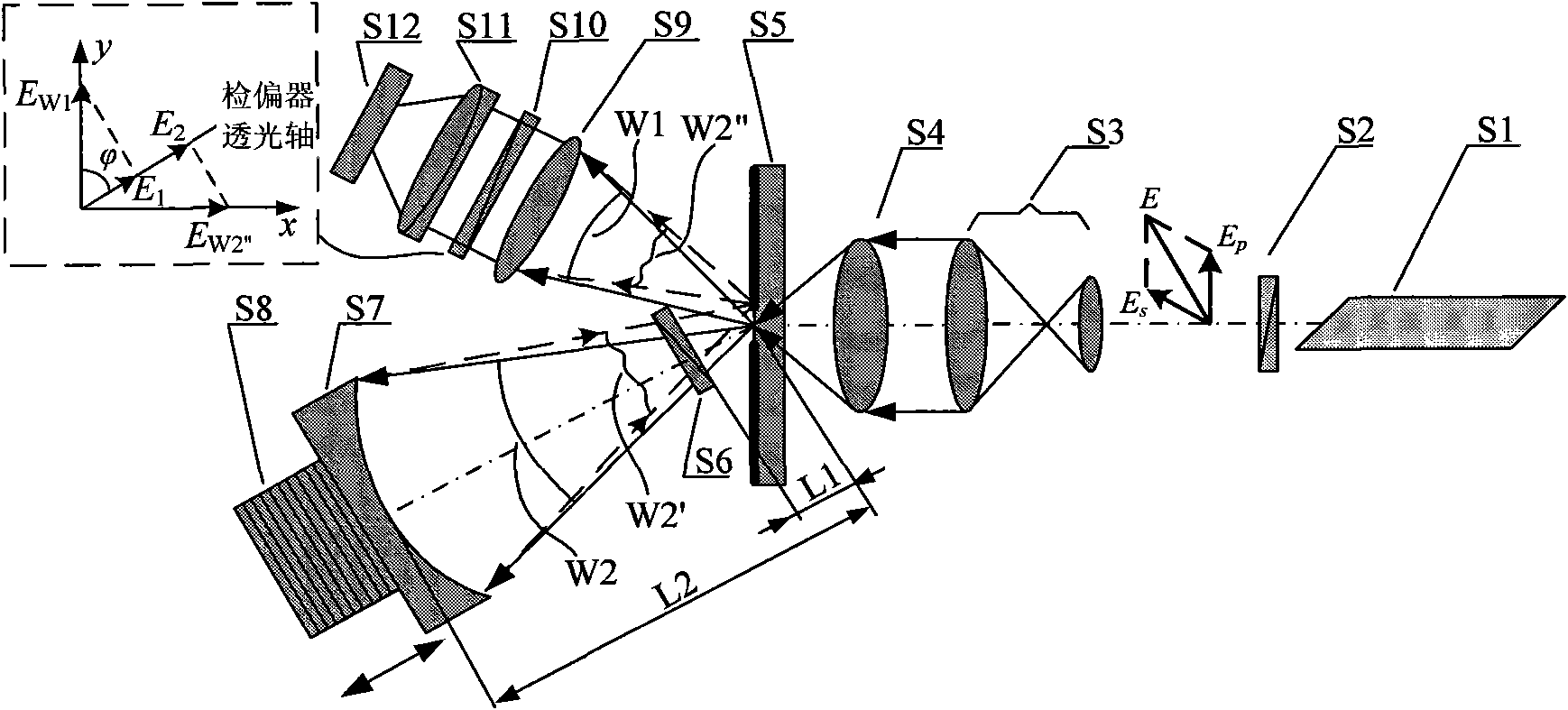

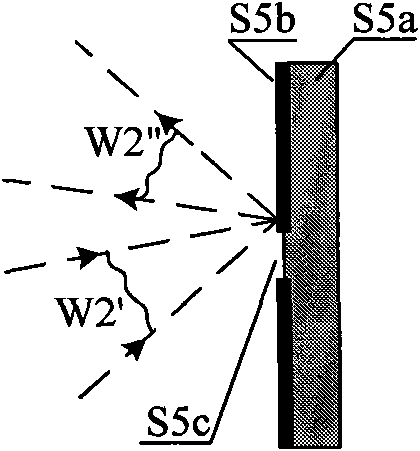

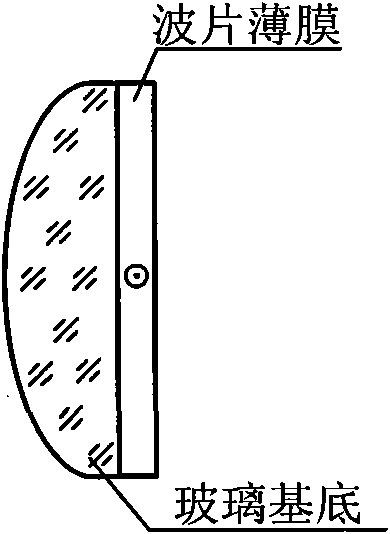

[0027] In the embodiment, the measured spherical surface S7 is a spherical surface with a radius of curvature of 180 mm and a numerical aperture (NA) of 0.65. The linearly polarized laser S1 obtains linearly polarized light through the half-wave plate S2, and generates parallel light through the collimator beam expander system S3, which is converged to the diffraction mask S5 through the microscope objective lens S4 with a magnification of 20× and an NA of 0.4 On the diffraction pinhole, a more ideal diffraction spherical wavefront is obtained. in figure 2 The diffraction mask shown is made of quartz glass substrate S5a, on which a chromium metal reflective film S5b with a thickness of 200nm (refractive index corresponding to 632.8nm wavelength is 2.65+3i) is plated, and is etched by convergent ion beam etching method. (Focused Ion Beam Etching, FIBE) process a diffraction pinhole S5c with a relatively ideal circularity on the metal film layer, and its diameter is taken as 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com